Safety drilling device for lead-acid battery leakage test

A technology for lead-acid batteries and drilling devices, applied in battery/battery leak testing, boring/drilling, maintenance and safety accessories, etc., capable of solving test errors, contamination of environmental equipment and experimenters, electrolyte splash or overflow To prevent splashing or overflowing, protect the safety of personnel and the environment, and achieve good human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

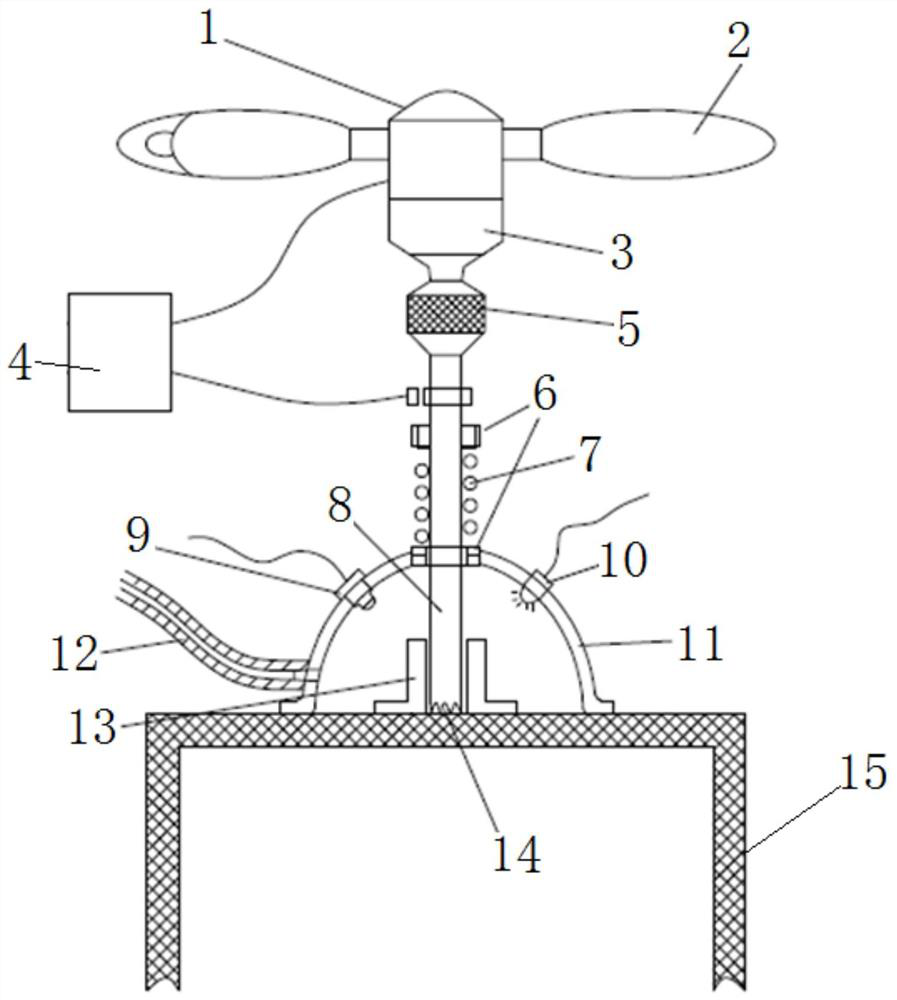

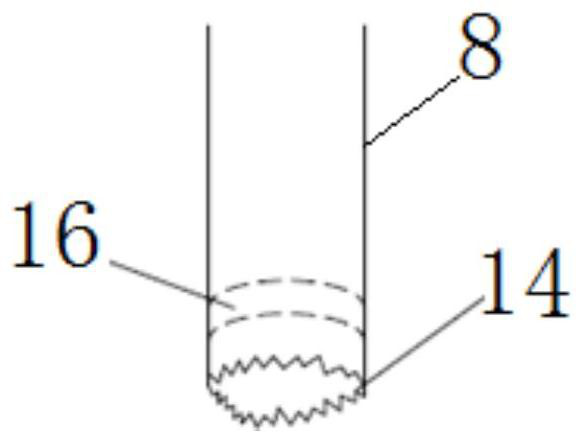

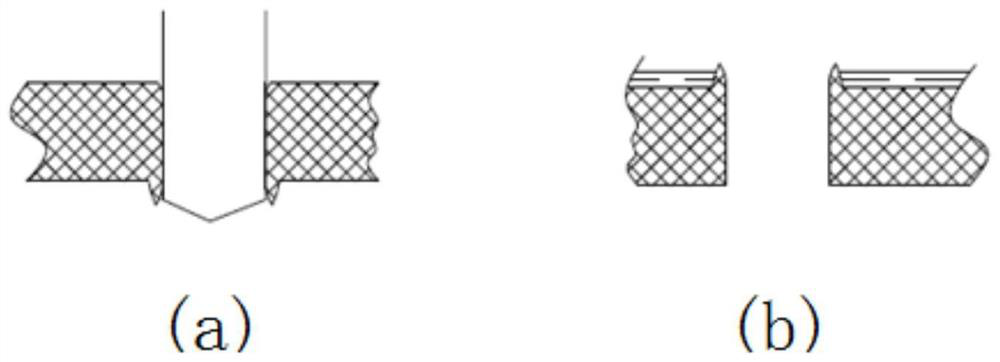

[0035] Such as figure 1 A safe drilling device for the leakage test of the lead-acid battery is shown, including a drilling unit, a protection unit that is sleeved outside the drilling unit and adapted to the surface of the lead-acid battery 15, and a drilling unit that is compatible with the drilling unit. A power-off protection system for the electrical connection of the hole unit. The drilling unit includes a power mechanism and a hollow tube 8 connected to the power mechanism. The bottom end of the hollow tube 8 is provided with sawtooth 14 .

[0036] Wherein, the power mechanism includes a DC motor 1 and a reducer 3 connected to the output shaft of the DC motor 1 , and a connecting head 5 is provided between the reducer 3 and the top of the hollow tube 8 . The serrations 14 are arranged on the bottom end of the hollow tube 8 in a ring shape. A pressing handle 2 is provided on the shell side of the DC motor 1 .

[0037] The protection unit includes a protective cover 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com