Self-active denitrification carrier material and preparation method and application thereof

A carrier material and denitrification technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve the problem of low denitrification rate, achieve the effect of improving stability and increasing denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

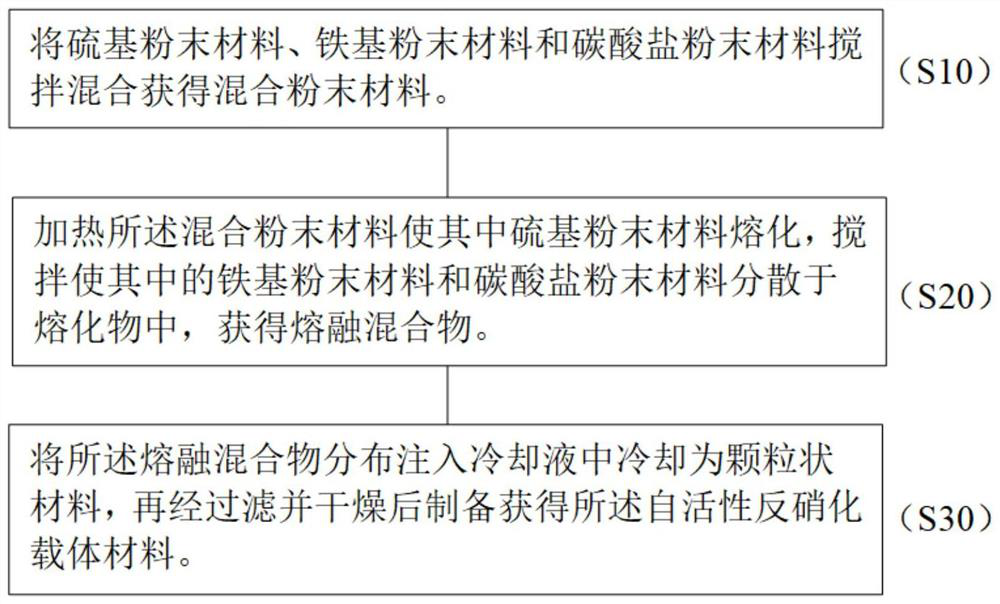

[0036] The embodiment of the present invention also provides the preparation method of the self-active denitrification carrier material as described above, refer to figure 1 , the preparation method comprises the steps of:

[0037]S10. Stir and mix the sulfur-based powder material, the iron-based powder material and the carbonate powder material to obtain a mixed powder material.

[0038] Specifically, the mass ratio among the sulfur-based powder material, the iron-based powder material and the carbonate powder material is selected to be in the range of (1-20):(1-10):(1-5) Inside, the particle size of each material powder is selected within the range of 100-200 mesh.

[0039] S20. Heating the mixed powder material to melt the sulfur-based powder material, stirring to disperse the iron-based powder material and carbonate powder material in the melt to obtain a molten mixture.

[0040] In a preferred solution, the heating temperature for heating the mixed powder material is 14...

Embodiment 1

[0048] The preparation process of the self-active denitrification carrier material in this embodiment is as follows:

[0049] 1. Mix elemental sulfur powder, reduced zero-valent iron powder and magnesite powder uniformly in a mass ratio of 3:1:1 to obtain a mixed powder material.

[0050] 2. Put the mixed powder material in a heating kettle, heat and melt the elemental sulfur powder in the mixture at 150°C to form liquid sulfur, and keep the temperature of the heating kettle at 150°C.

[0051] 3. Stir and mix the mixture at a frequency of 120r / min, so that the reduced zero-valent iron powder and magnesite powder are evenly dispersed in the liquid sulfur, and the CO is introduced at a low speed. 2 gas that encases CO in a liquid sulfur mixture 2 bubble.

[0052] 4. Wrap the CO 2 The mixed solution of bubbles is uniformly and stably injected into the cooling water through the mixed solution distributor, and the injection rate is 5mL / min.

[0053] 5. Cool the dripped mixed so...

Embodiment 2

[0055] The preparation process of the self-active denitrification carrier material in this embodiment is as follows:

[0056] 1. Mix elemental sulfur powder, sponge iron powder and magnesite powder evenly according to the mass ratio of 3:1:1 to obtain a mixed powder material.

[0057] 2. Put the mixed powder material in a heating kettle, heat and melt the elemental sulfur powder in the mixture at 150°C to form liquid sulfur, and keep the temperature of the heating kettle at 150°C.

[0058] 3. Stir and mix the mixture at a frequency of 120r / min, so that the reduced zero-valent iron powder and magnesite powder are evenly dispersed in the liquid sulfur, and the CO is introduced at a low speed. 2 gas that encases CO in a liquid sulfur mixture 2 bubble.

[0059] 4. Wrap the CO 2 The mixed solution of bubbles is uniformly and stably injected into the cooling water through the mixed solution distributor, and the injection rate is 5mL / min.

[0060] 5. Cool the dripped mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com