Quality-divided crystallization device and process capable of realizing zero discharge of high-salinity wastewater

A high-salt wastewater and crystallization device technology, which is applied in the direction of water pollutants, water/sewage treatment, frozen water/sewage treatment, etc., can solve problems such as high operating costs, difficulties in meeting the needs of enterprises, and complicated crystallization processes. Achieve the effects of reducing operating costs, significant economic and social benefits, and reducing operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

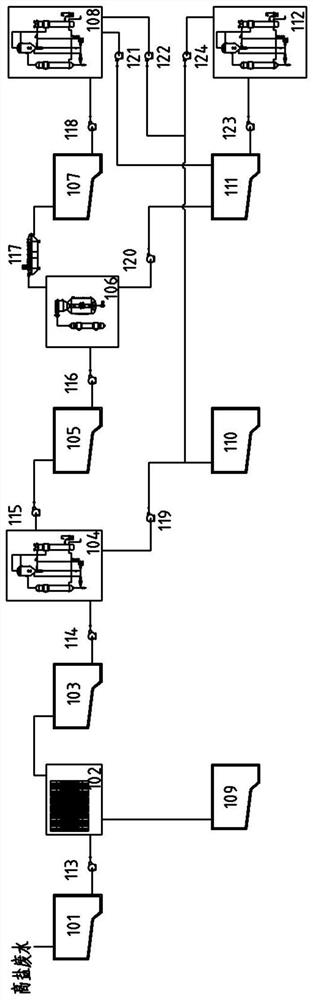

[0057] The difference between this embodiment and embodiment 1 is that in the high-salt wastewater with specific components, the salt-nitrate ratio (mass ratio of sodium chloride to sodium sulfate)≤1:1, the nitric acid recrystallization device 108 is omitted, and the The high brine in the dissolved brine pool 107 is sent to the evaporative crystallization device 104 by the nitric acid recrystallization water inlet pump 118, which simplifies the treatment process.

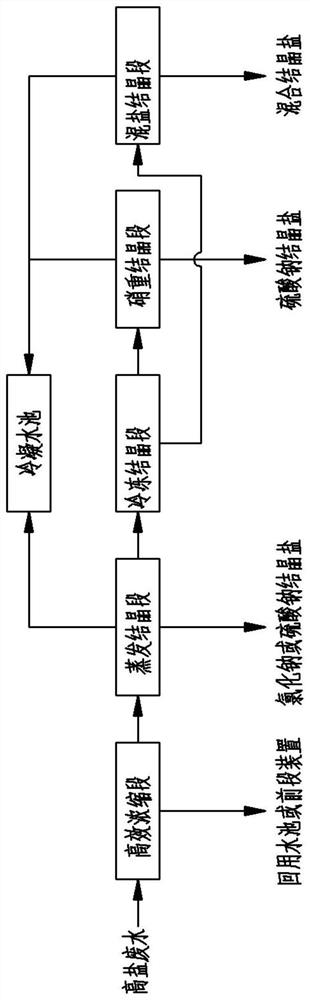

[0058] The process of this embodiment includes four parts: high-efficiency concentration, evaporative crystallization, freezing crystallization and mixed salt crystallization (reference example 1). Taking the concentrated salt wastewater to be treated in a typical coal chemical zero discharge device as an example, after being concentrated by the front-stage reuse water device , water volume 34m 3 / h, salt content 3.5%, of which, the main salts are sodium sulfate and sodium chloride, sulfate radical 22540mg / L, chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com