A heat-insulating, heat-preserving, and high-temperature-resistant coating for the surface of q235b steel and a preparation method thereof

A high-temperature-resistant coating, Q235B technology, applied in anti-corrosion coatings, fire-proof coatings, alkali metal silicate coatings, etc., can solve the problems of high thermal conductivity, large coating thickness, etc., achieve strong fire resistance, prevent bursting, and prevent cracking deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

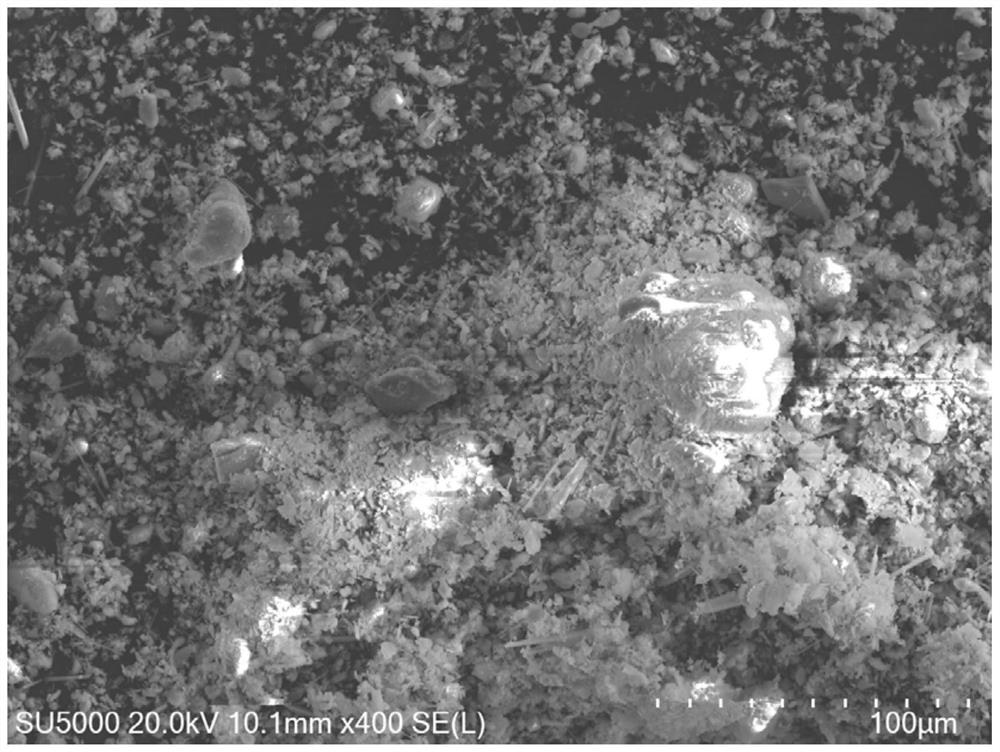

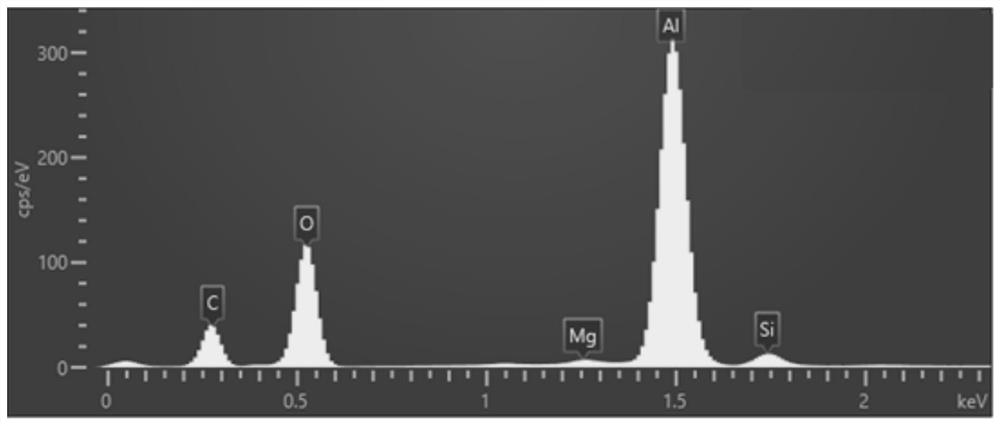

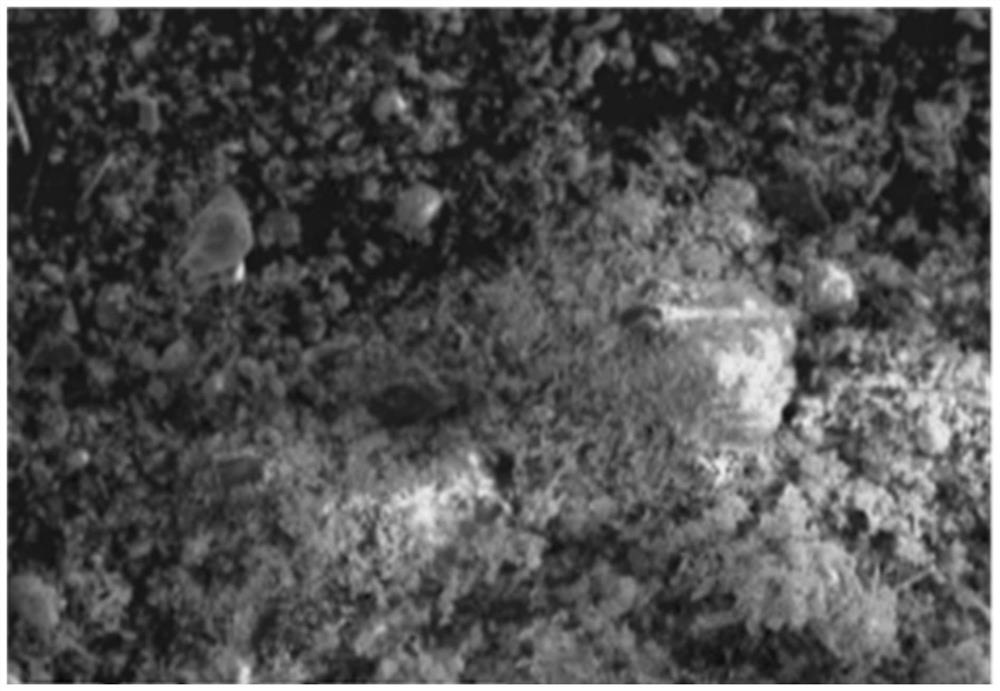

Image

Examples

specific Embodiment approach 1

[0043] Specific Embodiment 1: In this embodiment, a heat-insulating and heat-resisting high-temperature-resistant coating for the surface of Q235B steel consists of 11-22 parts by mass of sodium silicate, 0.4-0.8 parts of air-entraining agent, and 0.8-4 parts of thickening agent, 0.4-1.6 parts of corrosion inhibitor, 30-38 parts of alumina, 4-8 parts of fly ash, 1.6-3.2 parts of magnesium oxide, 0.8-4 parts of silicon carbide, 5-10 parts of aluminum powder and 15-20 parts Deionized water preparation.

specific Embodiment approach 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sodium silicate is sodium trimosilicate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the air-entraining agent is sodium petroleum sulfonate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com