Preparation method of Yunnan green tea

A green tea greening technology, applied in tea treatment before extraction, etc., can solve the problems of less research on processing technology, and achieve the effect of fully maintaining the contained substances, high temperature, and maintaining bright green

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

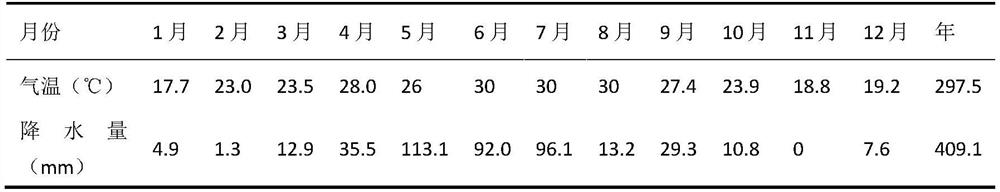

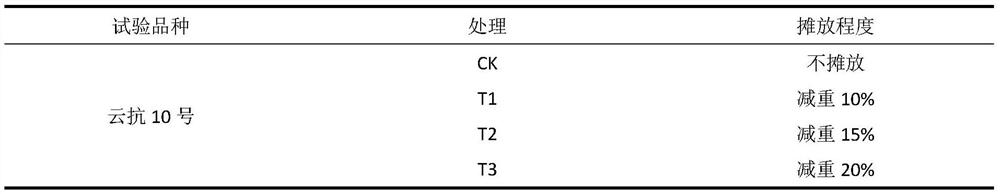

[0022] In this embodiment, Yunkang No. 10 is used as the test material, and 4 treatments are set: CK (no spreading), T1 (10% weight loss), T2 (15% weight loss), and T3 (20% weight loss), among which CK (not spread) is the experimental control. At the same time, four treatments CK (5 minutes), T1 (10 minutes), T2 (15 minutes), T3 (20 minutes) were set to each process four samples. Keeping the water loss withering, the initial temperature of the killing pot, the rolling time, the drying temperature, and the drying time, the chemical components contained in the tea polyphenols and caffeine of the four green tea samples were detected, and the data obtained from the experiment were analyzed. The sensory evaluation is based on the eight-factor tea evaluation method to evaluate the strands, color, tea soup, taste, etc. of the green tea produced in the test.

[0023] This test is divided into 16 pretreatments, each pretreatment fresh leaves (Yunkang No. 10) 4 kg (500 grams of finishe...

Embodiment 2

[0051] The specific process of the method described in this embodiment is as follows:

[0052] (1) The fresh leaves are first treated with ultraviolet rays, insecticides are sterilized, and then spread to keep the water loss rate of the fresh leaves at 20%.

[0053] (2) Finishing: The temperature of the finishing pot: the initial temperature is 214°C. Greening frequency: flip once every 5 seconds; amount of leaves: 2 kg. Finishing method: manual flipping and finishing.

[0054] (3) Kneading: Kneading method: cold kneading. Kneading machine model: 6CR–Z45. Kneading time: 20 minutes. Kneading degree: the cord is tight and there is less broken tea.

[0055] (4) Drying: The drying method is to bake green tea, tools: hand-pulled louver dryer; the first drying fire: temperature 100-120°C, time: 30 minutes. Baking for the second time: temperature 80-100°C, time: 20 minutes. The final moisture content is between 7% and 8%.

[0056] Table 6 Finishing test design table

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com