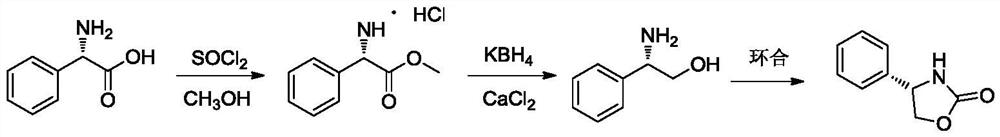

Method for synthesizing (S)-4-phenyl-2-oxazolidinone by micro-channel reactor

A technology of microchannel reactor and channel reactor, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, organic chemistry, etc., can solve the problems of uncontrollable reaction, high toxicity, unstable thermal effect, etc. Reduced risk, improved purity and improved yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

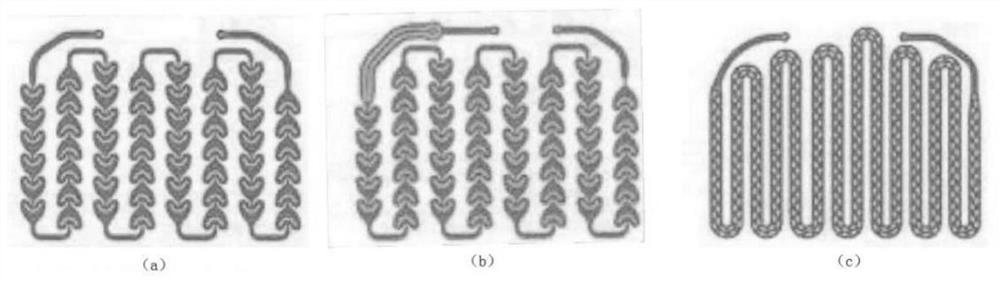

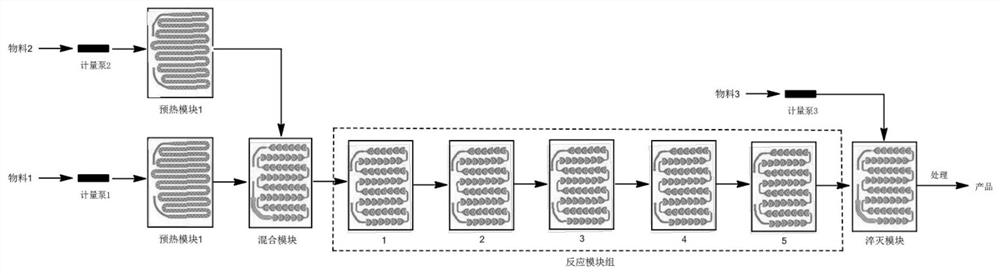

[0032] The present embodiment provides a kind of method that microchannel reactor synthesizes (S)-4-phenyl-2-oxazolidinone, as figure 1 and figure 2 As shown, the microchannel reactor adopted includes a preheating module, a mixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the mixing module is connected in series with the reaction module group, and the reaction module group and the quenching module group are connected in series. The off modules are connected in series.

[0033] 1). Weigh 100 g of raw material L-phenylglycinol and 7.5 g of triethylamine dissolved in 2 L of tetrahydrofuran to form material 1, and transport material 1 to the preheating module of the microchannel reactor for preheating;

[0034] 2). 87 g of triphosgene was weighed and dissolved in 1.5 L of tetrahydrofuran to form material 2, and 5% ammonia solution was transported as material 3 to the quenching mo...

Embodiment 2

[0037] The present embodiment provides a kind of method that microchannel reactor synthesizes (S)-4-phenyl-2-oxazolidinone, as figure 1 and figure 2As shown, the microchannel reactor adopted includes a preheating module, a mixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the mixing module is connected in series with the reaction module group, and the reaction module group and the quenching module group are connected in series. The off modules are connected in series.

[0038] 1). Weigh 120g of raw material L-phenylglycinol and 17.5g of triethylamine dissolved in 2.5L of tetrahydrofuran to form material 1, and transport material 1 to the preheating module of the microchannel reactor for preheating;

[0039] 2). 130 g of triphosgene was weighed and dissolved in 2.5 L of tetrahydrofuran to form material 2, and 10% ammonia solution was transported as material 3 to the quenching m...

Embodiment 3

[0042] The present embodiment provides a kind of method that microchannel reactor synthesizes (S)-4-phenyl-2-oxazolidinone, as figure 1 and figure 2 As shown, the microchannel reactor adopted includes a preheating module, a mixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the mixing module is connected in series with the reaction module group, and the reaction module group and the quenching module group are connected in series. The off modules are connected in series.

[0043] 1). Weigh 150 g of raw material L-phenylglycinol and 43 g of pyridine and dissolve in 2 L of dichloromethane to form material 1, and transport material 1 to the preheating module of the microchannel reactor for preheating;

[0044] 2). 146g of triphosgene was weighed and dissolved in 1.8L of dichloromethane to form material 2, and 10% ammonia solution was transported to the preheating module of the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com