Waterborne polyurethane, waterborne polyurethane coating and preparation method of waterborne polyurethane coating

A water-based polyurethane and polypropylene carbonate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor water resistance, solvent resistance and unsatisfactory mechanical properties, so as to reduce production costs and improve mechanical properties , Improve the effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

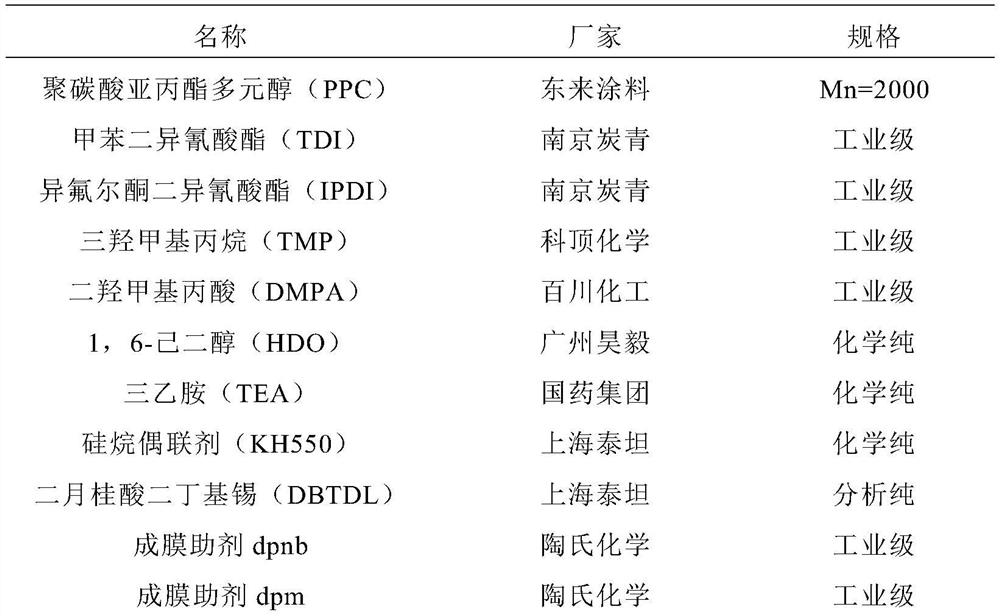

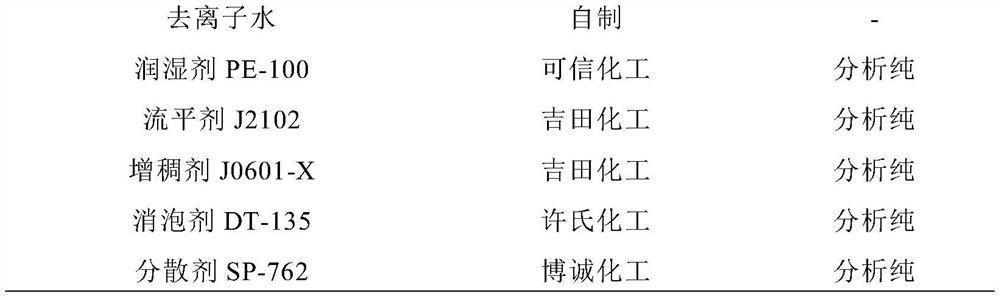

Embodiment 1

[0035] Pour 1000g of PPC into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 170g of TDI, 150g of IPDI and 50g of DMPA, and react at 85°C for 2h. Add 80g of TMP and 80g of HDO, and add catalyst 5g of DBTDL to react, use amine titration to determine the reaction end point, add KH550 with a total mass content of 1% for hydrolysis condensation and 30g of TEA for neutralization, add water to emulsify, and obtain modified waterborne polyurethane ①.

[0036] In this embodiment, PPC is polypropylene carbonate polyol, TDI is toluene diisocyanate, IPDI is isophorone diisocyanate, DMPA is dimethylolpropionic acid, TMP is trimethylolpropane, and HDO is 1 ,6-Hexanediol, DBTDL is dibutyltin dilaurate.

Embodiment 2

[0038] Pour 1000g of PPC into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 160g of TDI, 140g of IPDI and 40g of DMPA, and react at 85°C for 2h. Add 70g of TMP and 70g of HDO, and add catalyst 3g of DBTDL to react, use amine titration to determine the reaction end point, add KH550 with a total mass content of 3% for hydrolysis condensation and 25g of TEA for neutralization, add water to emulsify, and obtain modified water-based polyurethane ②.

Embodiment 3

[0040] Pour 1000g of PPC into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 180g of TDI, 160g of IPDI and 60g of DMPA, and react at 85°C for 2h. Add 90g of TMP and 90g of HDO, and add catalyst 7g of DBTDL to react, judge the reaction end point by amine titration method, add KH550 with a total mass content of 5% for hydrolysis condensation and 35g of TEA for neutralization, add water to emulsify, and obtain modified water-based polyurethane ③.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com