Instant high-glue alloy asphalt modified material as well as preparation method and application thereof

A kind of asphalt modification and glue alloy technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of poor thermal storage stability, insufficient aging performance, and large smoke pollution, so as to improve the service life and increase the effective surface area , Solve the effect of high energy consumption in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

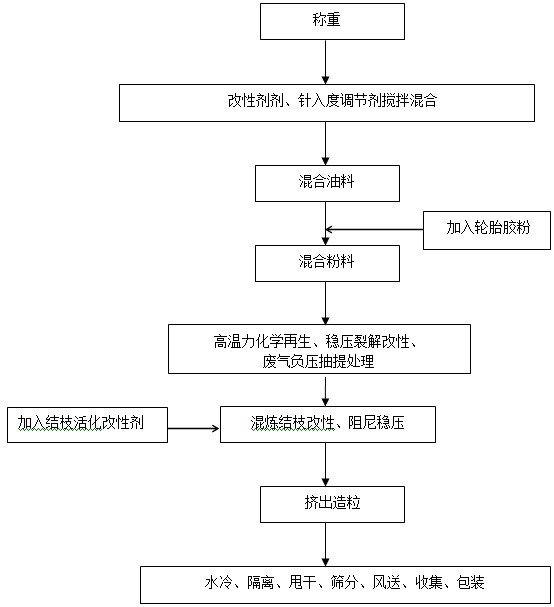

Method used

Image

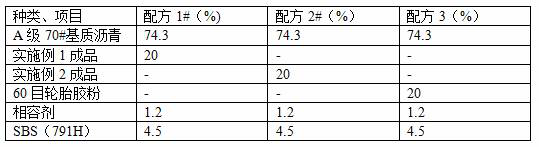

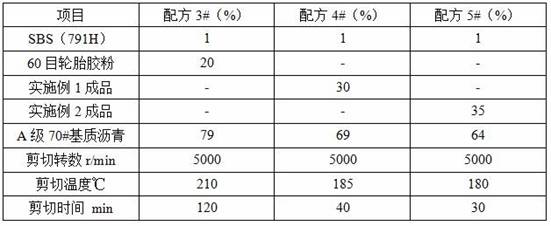

Examples

Embodiment 1

[0044] An instant high-adhesive alloy asphalt modified material, comprising the following components in parts by mass:

[0045] Truck tire rubber powder 100 parts

[0046] Heavy Bituminous Aromatic Oil 207 6 parts

[0047] 70# asphalt 6 parts

[0048] C9 resin 1.5 parts

[0049] Composite rock asphalt 5 parts

[0050] Among them, the truck tire rubber powder comes from steel wire radial tires with a specification of 9.00~12.00, and the mesh number is 40 mesh (screen residue ≤5%).

[0051] A preparation method of an instant high-adhesive alloy asphalt modified material, specifically comprising the following steps:

[0052](1) For the screening of raw materials, weigh each component according to the above formula.

[0053] (2) Heavy asphalt aromatic oil 207, 70# asphalt, and C9 resin were stirred in a mixing tank at 100°C for 1.5 hours, and mixed evenly to obtain a mixed oil.

[0054] (3) Stir the mixed oil and truck tire rubber powder in a mixing tank at 100°C for 300s, m...

Embodiment 2

[0059] An instant high-adhesive alloy asphalt modified material, comprising the following components in parts by mass:

[0060] Truck tire rubber powder 100 parts

[0061] Heavy Bituminous Aromatic Oil 207 7 parts

[0062] 70# asphalt 6 parts

[0063] C9 resin 1.5 parts

[0064] Composite rock asphalt 8 parts

[0065] Among them, the truck tire rubber powder comes from steel wire radial tires with a specification of 9.00~12.00, and the mesh number is 60 mesh (screen residue ≦8%).

[0066] A preparation method of an instant high-adhesive alloy asphalt modified material, specifically comprising the following steps:

[0067] (1) For the screening of raw materials, weigh each component according to the above formula.

[0068] (2) Heavy asphalt aromatic oil 207, 70# asphalt, and C9 resin were stirred in a mixing tank at 100°C for 1 hour, and mixed evenly to obtain a mixed oil.

[0069] (3) Stir the mixed oil and truck tire rubber powder in a mixing tank at 110°C for 280s, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com