Low-temperature quick-drying polymer-based conductive adhesive and preparation method thereof

A polymer and conductive adhesive technology, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of poor conductivity and poor system stability of conductive adhesives, achieve conductive network stability, promote curing, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

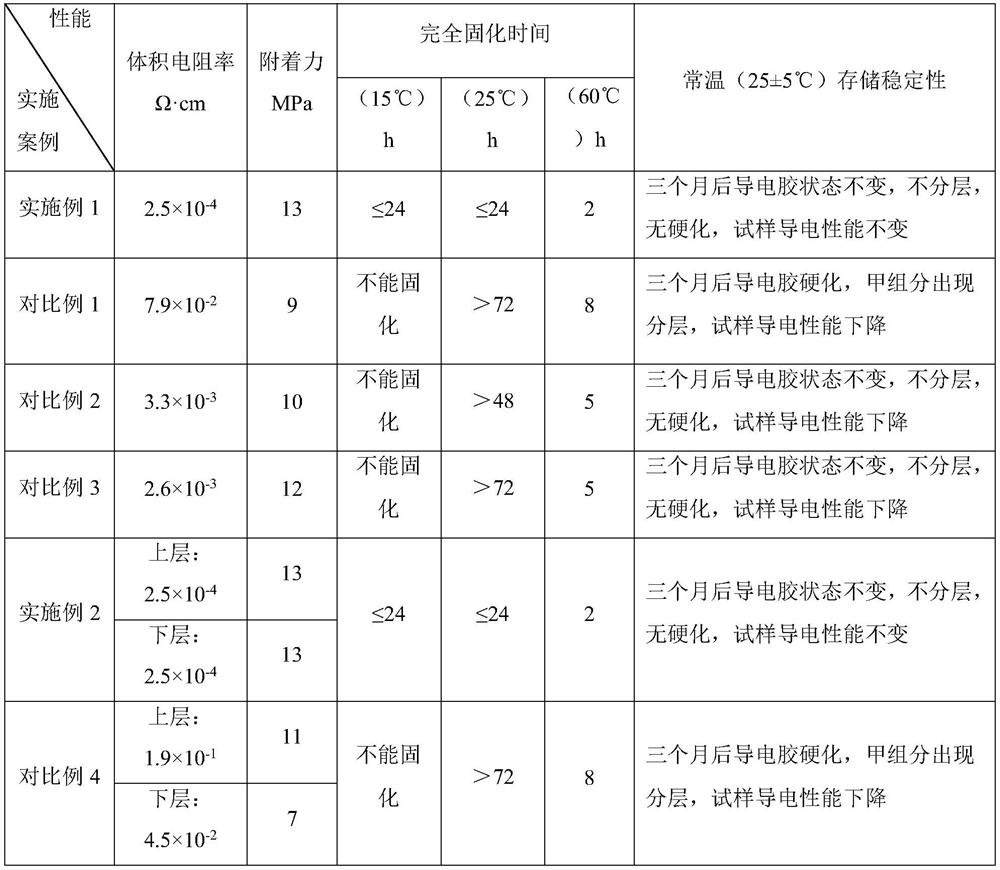

Embodiment 1

[0051] A low-temperature quick-drying polymer-based conductive adhesive of the present invention, comprising A component and B component, in parts by weight, A component includes: 13 parts of bisphenol A type epoxy resin, 80 parts of conductive filler; 4 parts of carboxyl liquid nitrile rubber, 1 part of triethylhexyl phosphoric acid, 2 parts of D6802; component B includes: 70 parts of polyamide curing agent, 10 parts of DDS, 20.5 parts of xylene, 0.5 part of n-butanol; among them, conductive filler It is a mixture of acidified and reduced micron copper powder and nanometer copper graphene. The preparation process is as follows:

[0052] 1) Add 100g of micron copper powder into 5% dilute sulfuric acid solution, ultrasonically treat for 40 minutes to remove oxides on the surface of the copper powder, rinse with deionized water after suction filtration, remove residual dilute sulfuric acid, and then transfer the copper powder to an anhydrous Sonicate in ethanol for 20 minutes an...

Embodiment 2

[0080] The formula and preparation method are the same as in Example 1. When preparing the sample, take the upper layer paste and the lower layer paste of component A and mix them with component B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com