Method for clean utilization of inferior heavy oil

A low-quality heavy oil, clean technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of waste of resources, environmental pollution, large amount of addition, etc., to reduce operating costs, simple mixing method, suppress strong focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

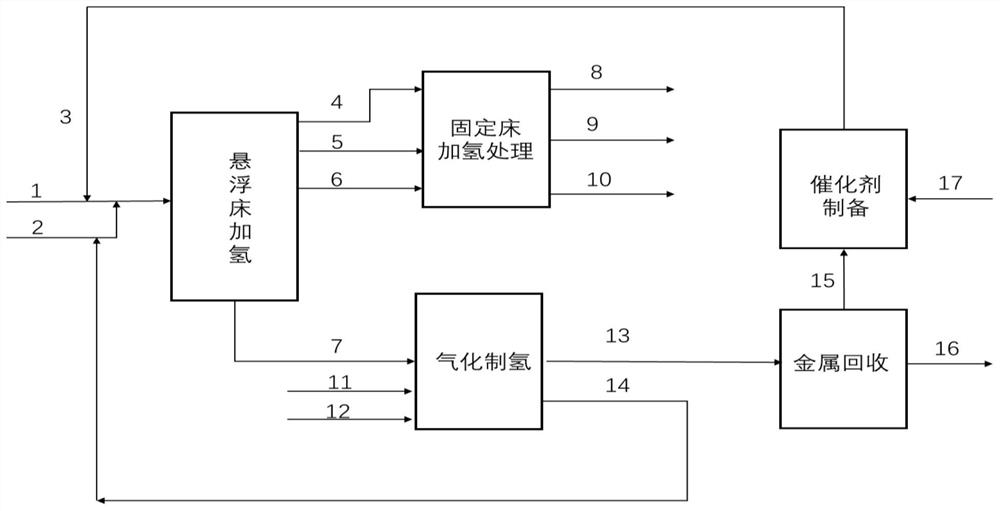

Method used

Image

Examples

Embodiment 1

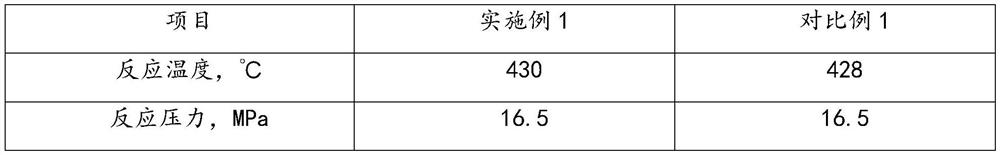

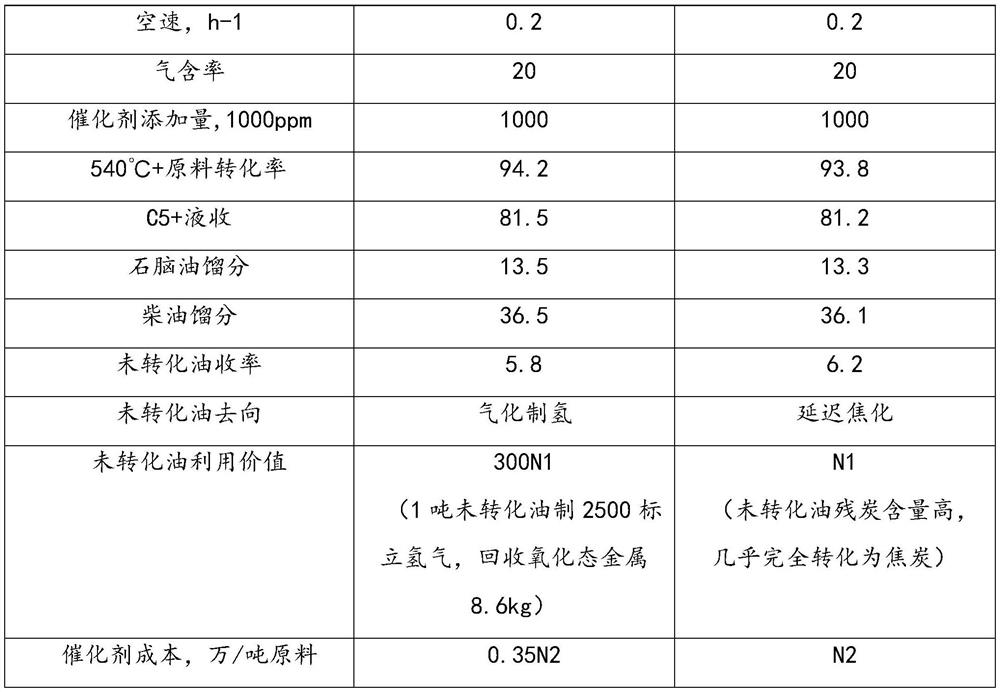

[0050] Take the vacuum residue and process it through conventional filtration and other means, add 1000ppm of molybdenum-based oil-soluble catalyst, the content of molybdenum in the catalyst is 15%, pass hydrogen to carry out the hydrothermal cracking reaction in the suspension bed reactor, the reaction pressure is 16.5MPa, Reaction temperature 430°C, volumetric space velocity 0.2h -1 , The gas holdup rate is 20%, and the gasoline fraction is obtained by separation after the reaction. Diesel oil fraction, wax oil fraction and unconverted oil fraction, the unconverted oil is fed into the gasification furnace to produce hydrogen, and the carbon cake produced is taken to the metal recovery system to recover molybdenum, nickel, and vanadium, and the recovered molybdenum is purified to prepare molybdenum-based oil-soluble catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com