Thermal control coating with designable solar absorptivity and preparation method

A technology of solar absorptivity and thermal control coating, applied in coating, metal material coating process, ion implantation plating, etc. Absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

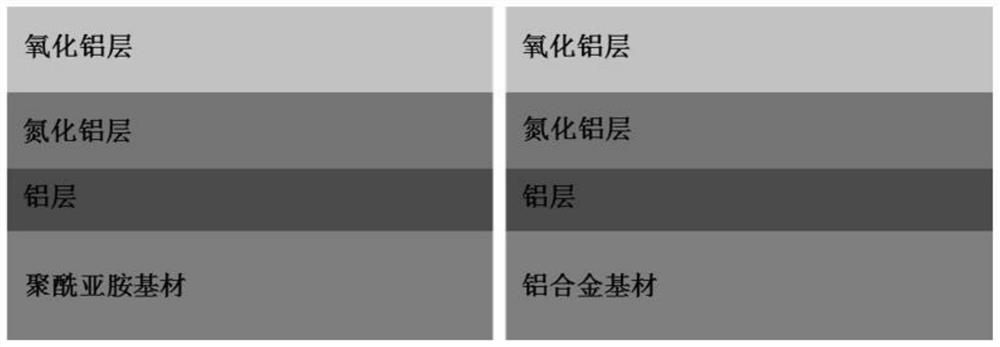

Method used

Image

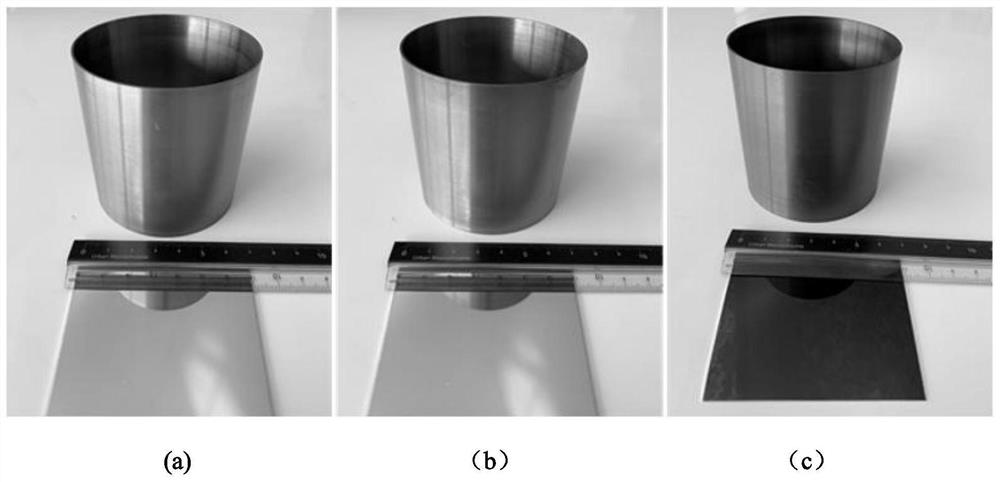

Examples

Embodiment 1

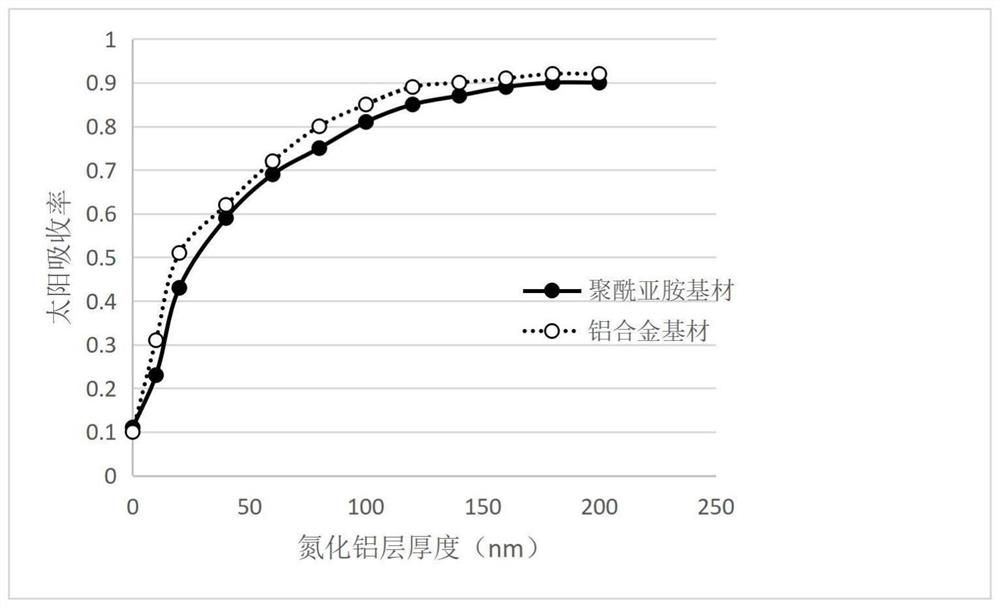

[0032] Put the aluminum alloy test piece (5 pieces) and the polyimide test piece (5 pieces) into the magnetron sputtering deposition equipment for film coating. Wherein, the thickness of the first layer of pure aluminum layer is 100nm, the thickness of the second layer of aluminum nitride layer is 0nm, and the thickness of the third layer of aluminum oxide layer is 10nm.

[0033] Aluminum coating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120sccm, voltage 550V; current 3A; sputtering time 500s. In this example no aluminum nitride layer was plated. Aluminum oxide plating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake rate 120sccm; power 1200W, sputtering time 10s.

[0034] Thermal radiation performance index test

[0035] Embodiment 1 test piece solar absorptivity test result is as follows table:

[0036] Numbering Polyimide Sample Solar Absorption Rate Aluminum alloy sample solar absorption rate ...

Embodiment 2

[0039] Put the aluminum alloy test piece (5 pieces) and the polyimide test piece (5 pieces) into the magnetron sputtering deposition equipment for film coating. Wherein, the thickness of the first layer of pure aluminum layer is 100nm, the thickness of the second layer of aluminum nitride layer is 10nm, and the thickness of the third layer of aluminum oxide layer is 10nm.

[0040] Aluminum coating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120sccm, voltage 550V; current 3A; sputtering time 500s. Aluminum nitride coating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1Pa; argon gas intake volume 120sccm; nitrogen gas intake volume 45sccm; voltage 550V; current 3A; sputtering time 250s. Aluminum oxide plating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120sccm; power 1200W, sputtering time 400s.

[0041] Thermal radiation performance index test

[0042] Embodiment 2 Test piece solar absorption rate te...

Embodiment 3

[0046] Put the aluminum alloy test piece (5 pieces) and the polyimide test piece (5 pieces) into the magnetron sputtering deposition equipment for film coating. Wherein, the thickness of the first layer of pure aluminum layer is 100nm, the thickness of the second layer of aluminum nitride layer is 80nm, and the thickness of the third layer of aluminum oxide layer is 10nm.

[0047] Aluminum coating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120sccm, voltage 550V; current 3A; sputtering time 500s. Aluminum nitride coating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120 sccm; nitrogen intake volume 45 sccm; voltage 550V; current 3A; sputtering time 500s. Aluminum oxide plating process parameters: vacuum degree 6×10 -1 Pa~8×10 -1 Pa; argon intake volume 120sccm; power 1200W, sputtering time 400s.

[0048] Thermal radiation performance index test

[0049] Embodiment 3 Test piece solar absorptivity test resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com