Porous graphene film prepared by laser processing method, preparation method and application thereof

A laser processing method, porous graphene technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve problems that do not meet the concept of green development, high condition requirements, cannot be removed, etc., and achieve high reusability , strong adaptability and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The small commercial laser engraving machine used in the present invention is a diode laser, and any power within 0-3W can be obtained by adjusting parameters, and it can be considered accurate within a certain error range. The polyimide film is purchased from DuPont, and the specific model is Kapton The color is light yellow, and the specific thickness is 0.0125-0.025mm, which can be considered accurate within a certain error range.

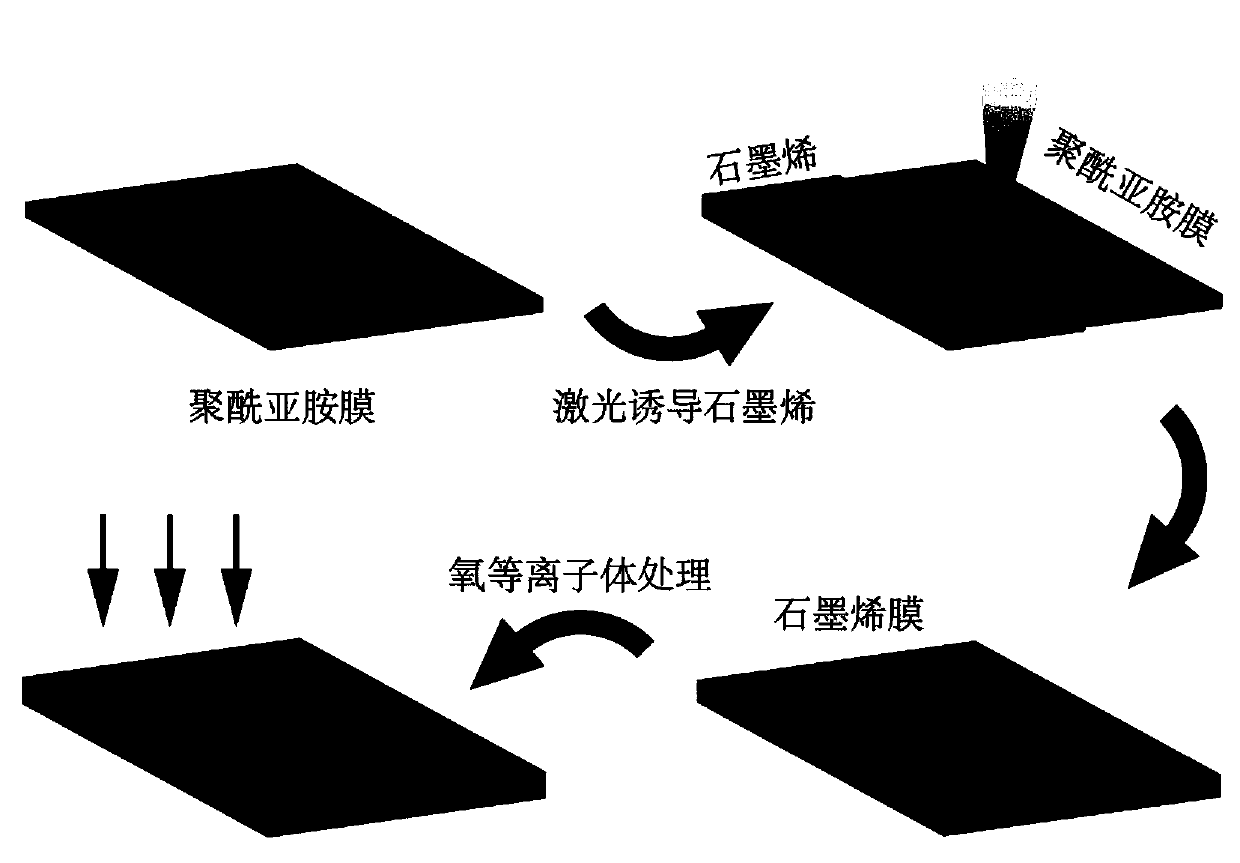

[0032] A preparation method of a porous graphene film prepared by a laser processing method, the specific steps are as follows:

[0033](1) Using laser processing technology to induce porous graphene film: cut the 0.025mm thick polyimide film into a square with a size of 20mm*20mm, and reserve a square double-sided processable area with an area of 15mm*15mm, here Cutting devices include but are not limited to scissors and the like. Then use a fixing device to fix the film on a flat substrate of 50mm*50mm*5mm. Here, the fixing device...

Embodiment 2

[0037] Such as Figure 5 Shown, a kind of application of the porous graphene film that utilizes the laser processing method to prepare in seawater desalination, specifically, will get two bottle mouth diameters and be the round mouth container of 5-10mm as seawater storage device and fresh water storage device, will The porous graphene material film prepared by the present invention is cut into a circle with a diameter of 5-10 mm, placed on the water surface with a seawater storage device, completely covering the water surface, and at the same time, a condensing device inclined from the seawater storage device to the fresh water storage device is added above the container. device, the condensing device is a 60mm*60mm*5mm glass plate, and the temperature of the condensing device is kept at 10-15°C; under the action of solar energy, the porous graphene film is placed on the surface of the liquid water, and the porous graphene film converts light energy into heat energy. The liqu...

Embodiment 3

[0040] The present invention also provides the application of using the porous graphene material for an evaporative humidifier, that is, the porous graphene film is used to convert light energy into heat energy, and the liquid water around the porous graphene film is evaporated, thereby increasing the environmental humidity, and Ensure that the water vapor released by the humidifier is clean, and avoid bringing bacteria and impurities in the water into the air during the humidification process of the traditional ultrasonic water mist humidifier.

[0041] Such as Image 6 As shown, the application of a porous graphene film prepared by laser processing method in the evaporative humidifier device, the processed film is cut according to the square area of 5mm*5mm to form a graphene film array, and placed in the humidifier water injection area and completely submerged in water. Depend on Image 6 It can be seen that in the evaporative humidifier, the graphene array is completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com