Amorphous silicon photoelectric layer thin film preparation method based on photoelectric tweezers equipment

A thin film preparation, amorphous silicon technology, applied in coatings, circuits, electrical components, etc., to improve performance and quality, improve conversion efficiency, and reduce costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

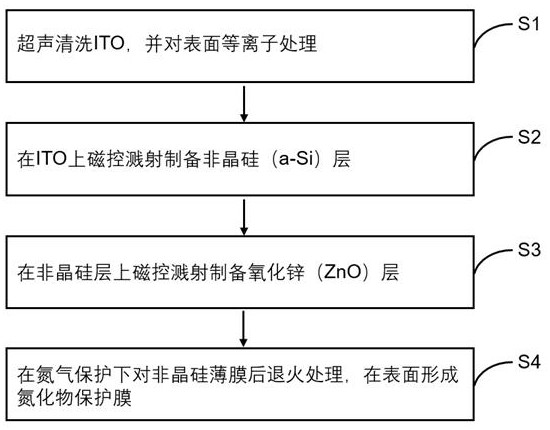

[0027] like figure 1 Shown is the process flow of the preparation method of the amorphous silicon photoelectric layer film based on the photoelectric tweezers equipment provided by the present invention. It can be seen from the figure that the preparation method includes: S1, ultrasonic cleaning of ITO, and plasma treatment of the surface; S2, on the ITO The amorphous silicon layer (a-Si) is prepared by magnetron sputtering; S3, the zinc oxide layer (ZnO) is prepared by magnetron sputtering on the amorphous silicon layer; S4, the amorphous silicon film is post-annealed under nitrogen protection, A nitride protective film is formed on the surface.

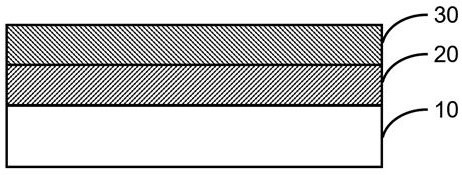

[0028] In step S1-4, as figure 2 As shown, on the substrate 10, an amorphous silicon layer 20 is formed by sputtering, and a zinc oxide layer 30 is sputtered on the amorphous silicon layer.

[0029] In a specific implementation process, the substrate 10 is made of transparent conductive glass ITO, and the conductive glass is succ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com