Amoxicillin and clavulanate potassium preparation and preparation method thereof

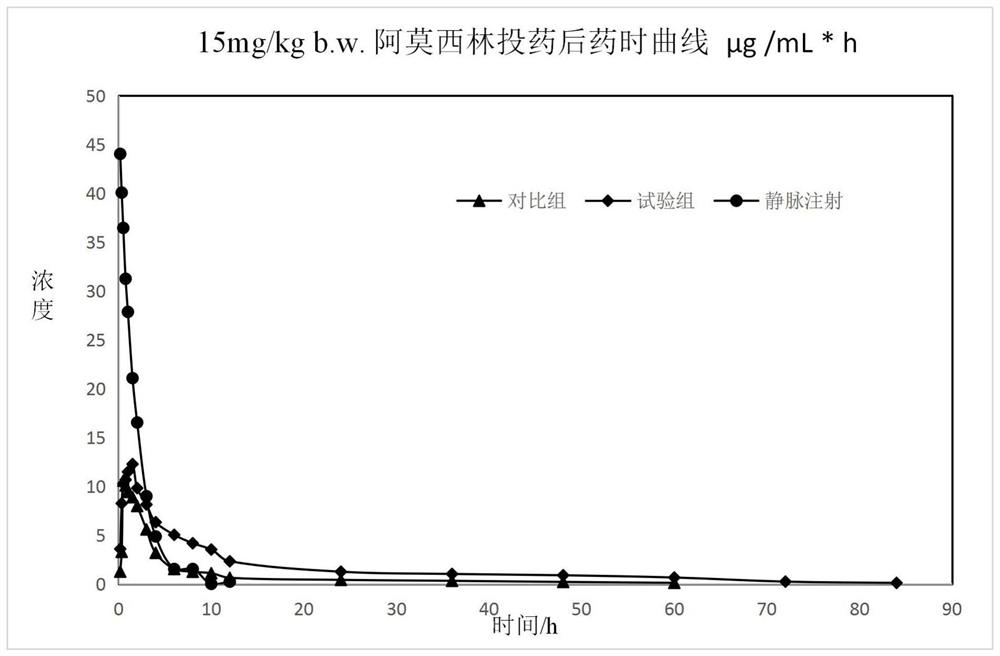

A technology of amoxicillin-clavulanate potassium and clavulanate potassium, which is applied in the direction of pharmaceutical formulas, medical preparations of non-active ingredients, inorganic non-active ingredients, etc., and can solve the difficulties and limitations of amoxicillin and clavulanate potassium Problems such as development and application of oral preparations, poor stability, etc., to achieve the effect of improving bioavailability, increasing residence time, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of amoxicillin clavulanate potassium preparation, described preparation is prepared by following method:

[0025] (1) Thoroughly mix 6.25g potassium clavulanate mixture with 15g tributyrin for 30min to obtain mixture A; uniformly mix mixture A with 11.5g amoxicillin, 3g citric acid, 3g sodium bicarbonate and 60g lactose for 30min , to obtain mixture B.

[0026] (2) Wet 2.15 g of konjac glucomannan superporous composite hydrogel with 13 ml of absolute ethanol to prepare an adhesive solution, and obtain solution C.

[0027] (3) Spray the solution C on the mixture B, and after the soft material is obtained, granulate with a 20-mesh swing granulator.

[0028] (4) Vacuum drying at room temperature for 6 hours to obtain amoxicillin-clavulanate potassium (4:1) granules.

Embodiment 2

[0030] A kind of amoxicillin clavulanate potassium preparation, described preparation is prepared by following method:

[0031] (1) Fully mix 6.25g of potassium clavulanate mixture with 25g tributyrin for 30min to obtain mixture A; uniformly mix mixture A with 11.5g of amoxicillin, 10g of citric acid, 10g of sodium bicarbonate, and 36g of lactose 30min, the mixture B was obtained.

[0032] (2) Wet 5 g of konjac glucomannan superporous composite hydrogel with 30 ml of absolute ethanol to prepare an adhesive solution, and obtain solution C.

[0033] (3) Spray the solution C on the mixture B, and after the soft material is obtained, granulate with a 20-mesh swing granulator.

[0034] (4) Vacuum drying at room temperature for 12 hours to obtain amoxicillin clavulanate potassium (4:1) granules.

Embodiment 3

[0036] A kind of amoxicillin clavulanate potassium preparation, described preparation is prepared by following method:

[0037] (1) Mix 6.25g of potassium clavulanate mixture with 20g of stearyl alcohol for 30min to obtain mixture A; mix mixture A with 11.5g of amoxicillin, 5g of citric acid, 5g of sodium bicarbonate, and 49g of lactose for 30min, Mixture B is obtained.

[0038] (2) Wet 2.5 g of polyvinylpyrrolidone with 15 ml of absolute ethanol to prepare an adhesive solution and obtain solution C.

[0039] (3) Spray the solution C on the mixture B, and after the soft material is obtained, granulate with a 20-mesh swing granulator.

[0040] (4) Vacuum drying at room temperature for 8 hours to obtain amoxicillin clavulanate potassium (4:1) granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com