Biomass-based hydrogel antibacterial wound dressing

A wound dressing and hydrogel technology, which is applied in medical science, bandages, etc., can solve the problems of mechanical properties, wound protection, wound exudate absorption and water retention, and antibacterial adhesion that cannot meet the requirements of single use. Good osmotic fluid absorption capacity, realization of performance, effect of improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

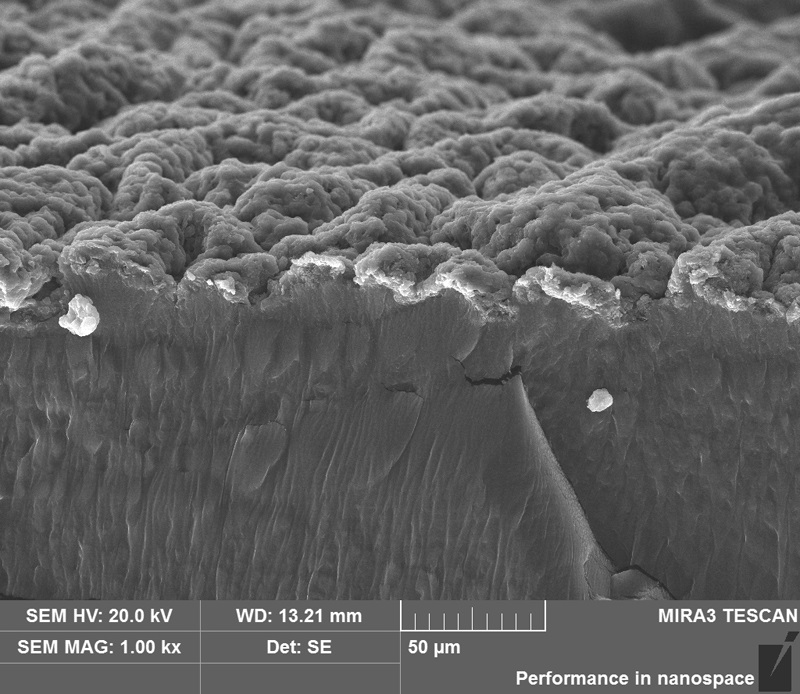

[0039] A biomass-based hydrogel antibacterial wound dressing is composed of double-layer gel film layers, including a surface layer of polyvinyl alcohol-polyacrylamide gel film layer and a bottom layer of chitosan-based antibacterial gel film layer.

[0040] (1) Preparation of surface polyvinyl alcohol-polyacrylamide gel film layer:

[0041] Use glycerin / water as a mixed solvent, dissolve polyvinyl alcohol at 90°C to obtain a certain concentration of polyvinyl alcohol solution I for use, and mix a certain proportion of monomer acrylamide, cross-linking agent N, N'-methylene Add bisacrylamide and initiator ammonium persulfate into deionized water at room temperature and stir until dissolved to form a uniform solution II. Then add a certain amount of polyvinyl alcohol solution I to solution II. After stirring evenly, add initiator HCl to the solution to promote Agent tetramethylethylenediamine, cross-linking agent glutaraldehyde, stirred at high speed within 2 minutes, then pour...

Embodiment 2

[0056] A biomass-based hydrogel antibacterial wound dressing is composed of double-layer gel film layers, including a surface layer of polyvinyl alcohol-polyacrylamide gel film layer and a bottom layer of chitosan-based antibacterial gel film layer.

[0057] Further, its preparation process includes the following steps:

[0058] (1) Preparation of surface polyvinyl alcohol-polyacrylamide gel film layer:

[0059] Use glycerin / water as a mixed solvent, dissolve polyvinyl alcohol at 92°C to obtain a certain concentration of polyvinyl alcohol solution I for use, and mix a certain proportion of monomer acrylamide, cross-linking agent N, N'-methylene Add bisacrylamide and initiator ammonium persulfate into deionized water at room temperature and stir until dissolved to form a uniform solution II. Then add a certain amount of polyvinyl alcohol solution I to solution II. After stirring evenly, add initiator HCl to the solution to promote Agent tetramethylethylenediamine, cross-linkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com