Slope crystallization and solid-liquid separation system

A solid-liquid separation and crystallization system technology, applied in crystallization separation, filtration separation, solution crystallization, etc., can solve the problems of high energy consumption and low economic benefit, and achieve the effect of eliminating crushing, high value and reducing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

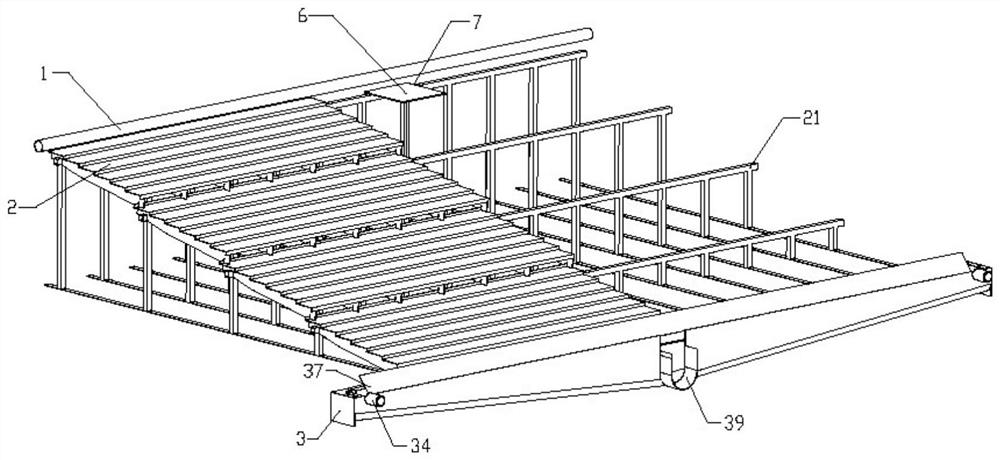

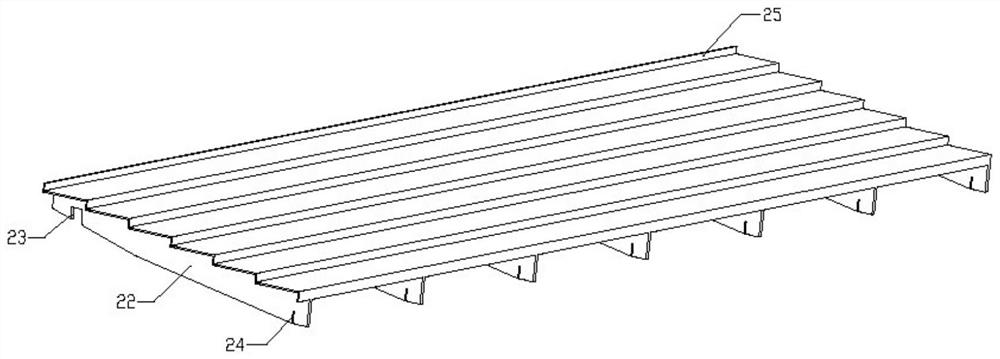

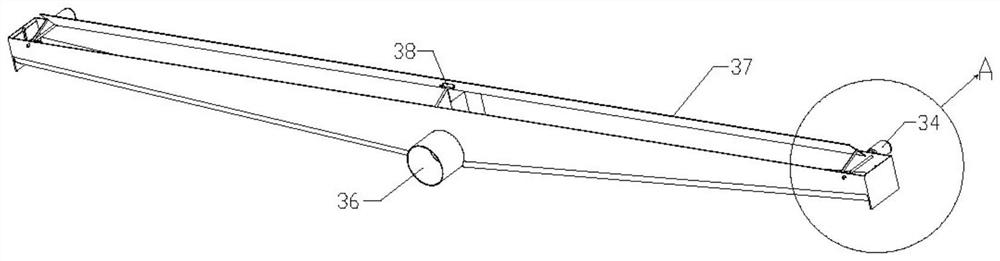

[0033] Such as Figure 1 to Figure 5 As shown, a slope crystallization and solid-liquid separation system includes a brine buffer tank, a slope crystallization system, and a solid-liquid separation system for separating the mother liquor and crystals output from the slope crystallization system. The brine buffer tank is located below the slope crystallization system. It is connected with the brine distribution system set on the top of the slope crystallization system through pipelines, and the solid-liquid separation system is located at the bottom of the slope crystallization system.

[0034] Among them, the brine buffer tank is set under the cover of the inclined plate assembly of the slope crystallization system, which can avoid rainwater diluting the brine when it rains. The saturated brine in the brine buffer tank is evenly spread on the top of the slope through the connecting pipe, and drips down along the slope surface The falling film is formed, the brine undergoes ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com