Alumina-titanium oxide composite carrier preparation method

A technology of composite carrier and titanium oxide, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems such as easy pollution of the environment, achieve environmental pollution prevention, excellent low-temperature hydrogenation activity, and avoid environmental problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

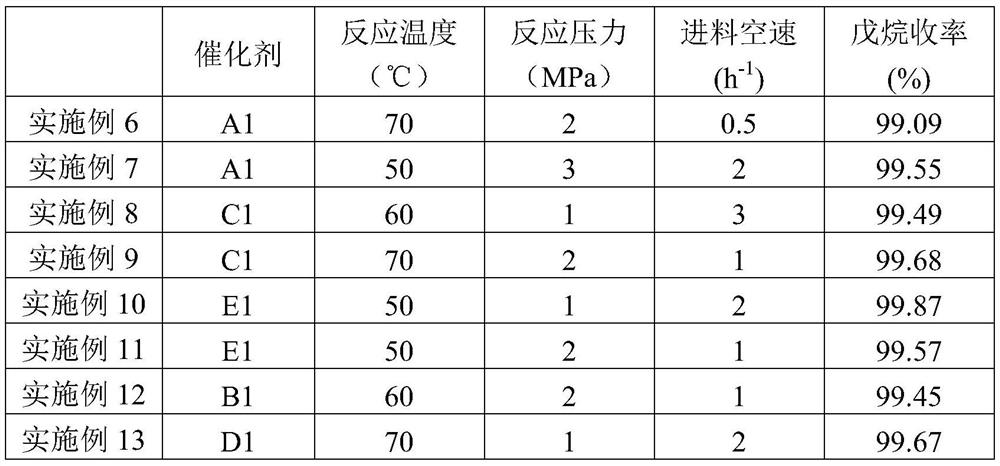

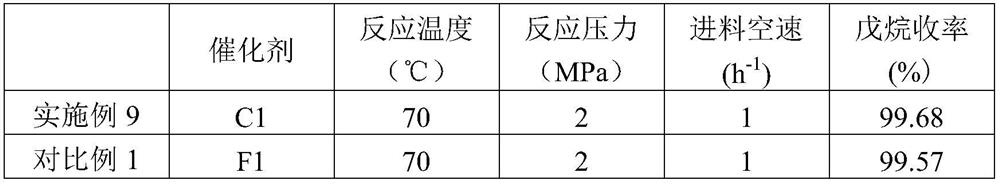

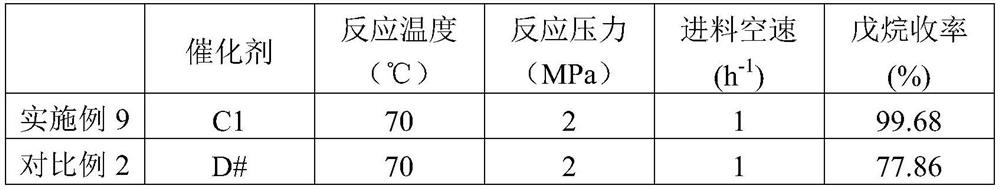

Examples

Embodiment 1

[0030] The aluminum sulfate solution of 0.9mol / L and the titanium sulfate solution of 0.24mol / L and the sodium hydroxide solution of 0.3mol / L flow into the container simultaneously, wherein the volume ratio of the aluminum sulfate solution and the titanium sulfate solution is 1:1, At a temperature of 80°C, control the amount of sodium hydroxide solution so that the pH value of the co-current solution is controlled at 8.5 to form alumina-titanium oxide co-precipitates, which are washed repeatedly with deionized water to remove sulfate ions, and then used The reverse osmosis membrane filters out the sodium ions in the solution, and finally obtains the alumina-titania filter cake, which is extruded and dried at 110°C for 10 hours, and then calcined at 600°C for 6 hours to obtain the alumina-titania composite Carrier A. Among them, aluminum oxide accounts for 82.2wt%, titanium oxide accounts for 17.1wt%, and the sodium ion content is 0.7wt%.

Embodiment 2

[0032] The aluminum sulfate solution of 0.56mol / L, the titanium sulfate solution of 0.22mol / L and the potassium hydroxide solution of 0.3mol / L flow into the container, wherein the volume ratio of the aluminum sulfate solution and the titanium sulfate solution is 1:1, At a temperature of 80°C, adjust the amount of sodium hydroxide solution so that the pH value of the co-current solution is controlled at 8 to generate alumina-titanium oxide co-precipitates, which are washed repeatedly with deionized water to remove sulfate ions, and then used Potassium ions in the solution were removed by reverse osmosis membrane filtration to obtain alumina-titania filter cake, which was extruded and dried at 110°C for 11 hours, and then calcined at 800°C for 5 hours to obtain alumina-titania composite support b. Among them, aluminum oxide accounts for 76.1wt%, titanium oxide accounts for 23wt%, and potassium ion content is 0.9wt%.

Embodiment 3

[0034]The aluminum sulfate solution of 0.86mol / L, the titanium sulfate solution of 0.26mol / L and the potassium hydroxide solution of 0.1mol / L flow into the container simultaneously, wherein the volume ratio of the aluminum sulfate solution and the titanium sulfate solution is 1:1, At a temperature of 80°C, adjust the amount of sodium hydroxide solution so that the pH value of the co-current solution is controlled at 9 to form alumina-titanium oxide co-precipitates, which are washed repeatedly with deionized water to remove sulfate ions, and then use Potassium ions in the solution were filtered out by reverse osmosis membrane to obtain alumina-titania filter cake, which was extruded and dried at 120°C for 12 hours, and then calcined at 800°C for 7 hours to obtain alumina-titania composite support c. Among them, aluminum oxide accounts for 80.2wt%, titanium oxide accounts for 19.1wt%, and potassium ion content is 0.7wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com