Composite aluminum-plastic film for power battery

A power battery and composite aluminum technology, which is applied in the field of composite aluminum-plastic film, can solve the problems of short service life of lithium-ion batteries, poor electrolyte resistance of aluminum-plastic film materials, adhesive force, and limitations in stamping and forming performance. Resistance to electrolyte corrosion, avoiding the entry of water vapor and oxygen, and enhancing the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

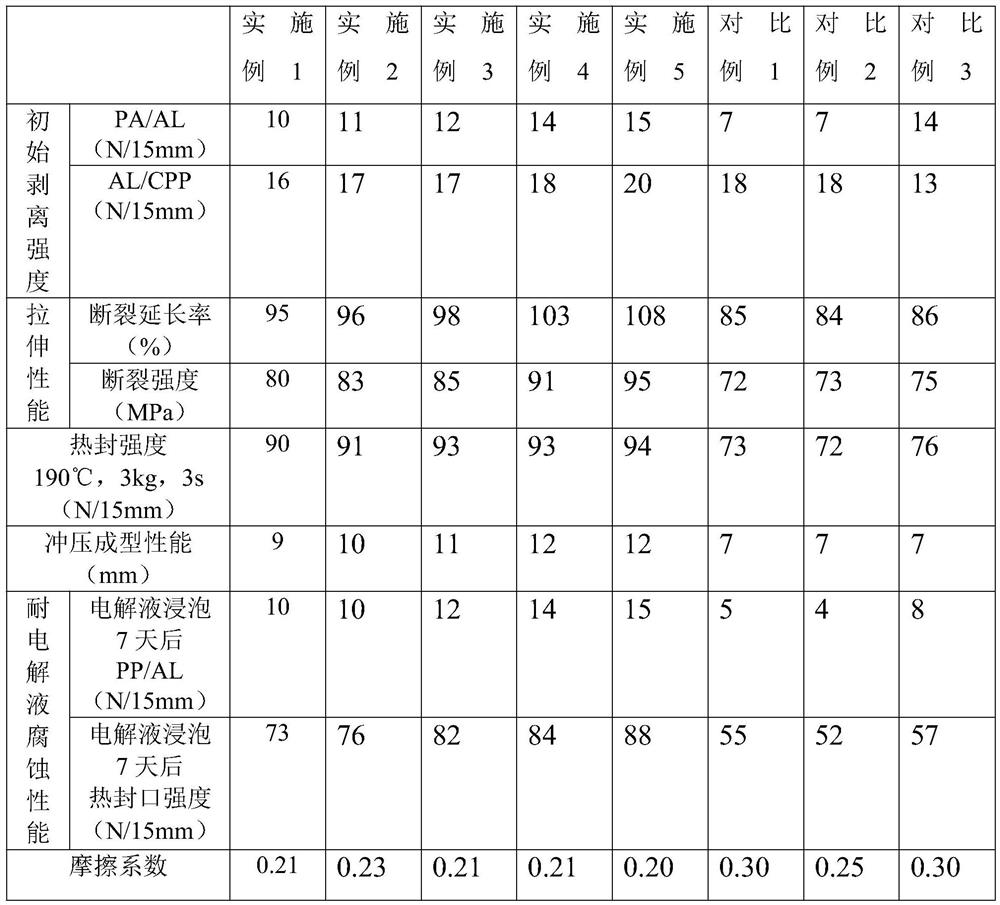

Examples

Embodiment 1

[0045] A composite aluminum-plastic film for power batteries, mainly composed of an aluminum foil layer, a polypropylene layer and an outer protective layer by co-extrusion through a casting process, and the aluminum foil layer and the outer protective layer are bonded by a first adhesive , the aluminum foil layer and the polypropylene layer are bonded by a second adhesive;

[0046] The outer protective layer is composed of a nylon film and a protective layer coated on the surface of the nylon film. The protective layer includes 1% phenol novolac epoxy resin, 70% polyvinylidene chloride resin emulsion and the balance of ethanol;

[0047] The first binder includes the following raw materials in parts by weight: 10 parts of polyester polyol, 5 parts of polyether polyol, 3 parts of single-walled carbon nanotubes, 0.1 part of toluene diisocyanate, 2 parts of bisphenol A epoxy resin, 0.2 parts of silane coupling agent, 3 parts of acetylacetone blocked polyisocyanate, 50 parts of et...

Embodiment 2

[0050] A composite aluminum-plastic film for power batteries, mainly composed of an aluminum foil layer, a polypropylene layer and an outer protective layer by co-extrusion through a casting process, and the aluminum foil layer and the outer protective layer are bonded by a first adhesive , the aluminum foil layer and the polypropylene layer are bonded by a second adhesive;

[0051] The outer protective layer is composed of a nylon film and a protective layer coated on the surface of the nylon film. The protective layer includes 35% o-cresol novolac epoxy resin, 78% polyvinyl acetate emulsion and the balance of ethanol;

[0052] The first binder includes the following raw materials in parts by weight: 12 parts of acrylic-modified polyester polyols, 8 parts of epoxy resin-modified polyether polyols, 4 parts of multi-walled carbon nanotubes, 0.3 parts of toluene diisocyanate, 3 parts of epoxy resin, 0.4 part of silane coupling agent, diethyl malonate 4 parts of ester-blocked po...

Embodiment 3

[0055] A composite aluminum-plastic film for power batteries, mainly composed of an aluminum foil layer, a polypropylene layer and an outer protective layer by co-extrusion through a casting process, and the aluminum foil layer and the outer protective layer are bonded by a first adhesive , the aluminum foil layer and the polypropylene layer are bonded by a second adhesive;

[0056] The outer protective layer is composed of a nylon film and a protective layer coated on the surface of the nylon film. The protective layer includes 5% bisphenol A novolac epoxy resin, 85% polyacrylate emulsion and the balance of ethanol;

[0057] The first binder includes the following raw materials in parts by weight: 10 parts of acrylic-modified polyester polyol, 10 parts of acrylic-modified polyether polyol, single-walled carbon nanotubes and multi-walled carbon with a mass ratio of 1:8 5 parts of mixture of nanotubes, 0.5 parts of toluene diisocyanate, epoxy resin 2- 5 parts, 0.5 parts of sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com