Multifunctional polypropylene melt-blown material and preparation method thereof

A polypropylene melt-blown, multi-functional technology, applied in the field of polypropylene melt-blown materials, can solve the problems of cumbersome production process, uneven mixing, high energy consumption, etc., and achieve the goals of simplified production process, energy saving and high economic added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

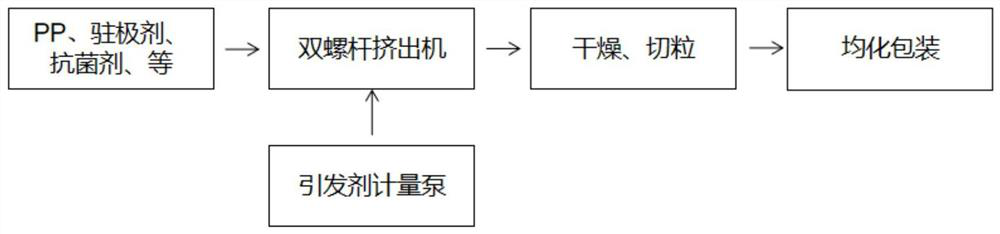

Method used

Image

Examples

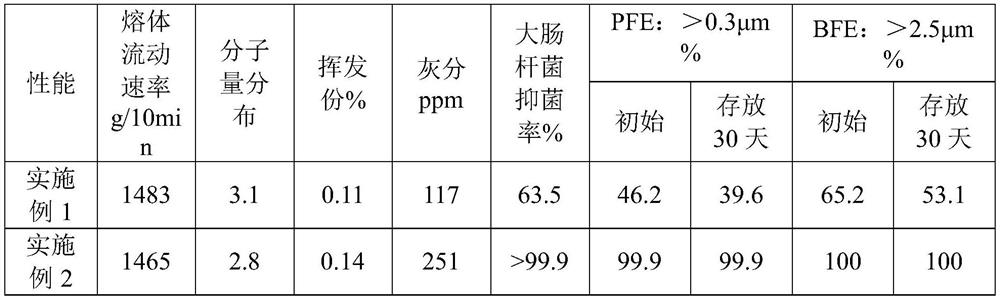

Embodiment 1

[0039] Weigh 50kg of PP-H-GD-230 polypropylene, transport it to the co-rotating twin-screw extruder through the feeding screw, and then inject 251.3g of di-tert-butyl peroxide into the twin-screw extruder by the metering pump, melt Extrude the strands after blending, the extruded strands are cooled, dried, and pelletized, wherein the flow rate of the initiator is set at 15mL / min to 25mL / min, and the screw speed of the twin-screw extruder is at 200RPM to 250RPM. There are a total of 16 zones in the extrusion cylinder, and the temperature range of the 16 zones is set within the range of 160°C to 250°C; the multifunctional polypropylene melt blown material is obtained; the obtained multifunctional polypropylene melt blown material is produced through a homogenization bin finished product.

Embodiment 2

[0041] (1) Weigh 153.4g of nanoscale tourmaline powder, 102.2g of quantum energy particles, and 153.4g of powdered titanate coupling agent, and perform high-speed mechanical mixing in advance to form a mixture of functional additives.

[0042] (2) After mixing PP-H-GD-230 polypropylene 50kg, 1010 antioxidant 51.1g, 168 antioxidant 51.1g, calcium stearate 102.2g with the functional additive mixture obtained in (1), the Stir until well combined to form a mixture.

[0043] (3) The compound obtained in (2) is conveyed to the co-rotating twin-screw extruder through the feeding screw earlier, then 511.2 g of di-tert-butyl peroxide is squeezed into the twin-screw extruder by the metering pump, and melted together Extrude the strips after mixing, the extruded strips are cooled, dried, and pelletized. There are 16 zones in total, and the temperature range of the 16 zones is set within the range of 160°C to 250°C; the multifunctional polypropylene meltblown material is obtained; the ob...

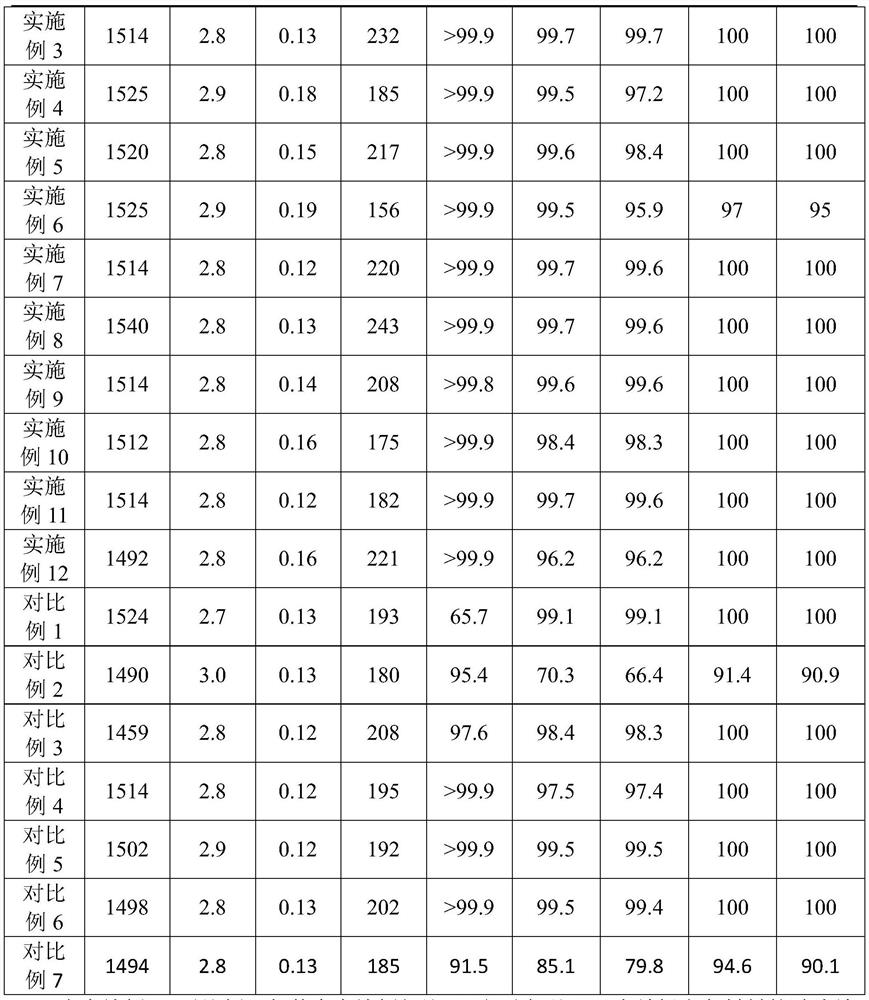

Embodiment 3

[0045] (1) Weigh 127.6g of nanoscale tourmaline powder, 76.5g of quantum energy particles, and 102g of powder titanate coupling agent, and perform high-speed mechanical mixing in advance to form a functional additive mixture;

[0046] (2) After weighing 50kg of powder PP-H-GD-230 polypropylene, 51g of 1010 antioxidant, 51g of 168 antioxidant, 102g of calcium stearate and the mixture of functional additives obtained in (1), the Stir until well combined to form a mixture;

[0047] (3) The compound obtained in (2) is conveyed to the co-rotating twin-screw extruder through the feeding screw earlier, then 510.2 g of di-tert-butyl peroxide is squeezed into the twin-screw extruder by the metering pump, and melted together Extrude the strip after mixing, the extruded strip is cooled, dried and pelletized, wherein the flow rate of the initiator is set at 15mL / min~25mL / min, the screw speed of the twin-screw extruder is at 200RPM~250RPM, the extruder There are 16 zones in total for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com