Inner wall anti-drag environment-friendly coating for long-distance pipeline and preparation method thereof

An environmentally friendly coating and pipeline technology, applied in the field of coatings, can solve problems such as the great impact on the health of front-line operators, achieve excellent anti-sag performance, improve stain resistance, and reduce surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

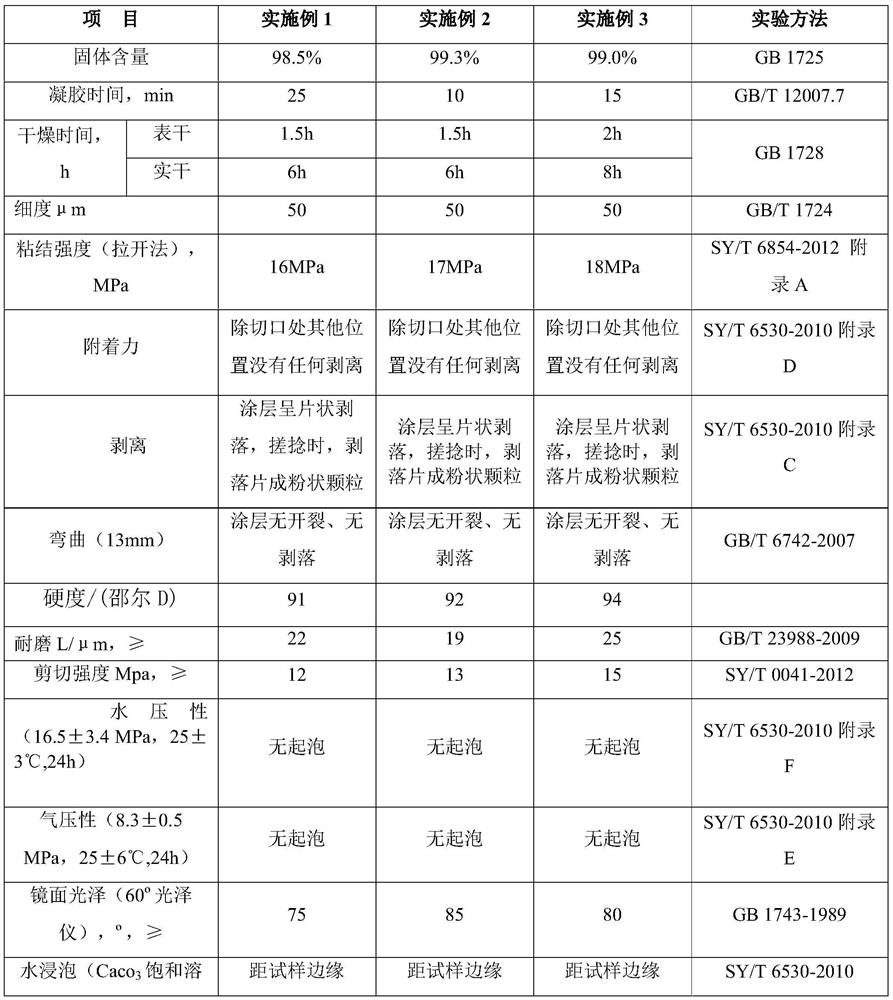

Examples

Embodiment 1-3

[0034] Polyurethane modified epoxy resin:

[0035] Polyurethane modified epoxy resin is prepared by the raw materials of following weight fraction:

[0036] 1,4 Butanediol diglycidyl ether: 202 parts

[0037]Ethylene glycol amine: 38.5 parts

[0038] IPDI: 222 copies

[0039] Polypropylene glycol (PPG400): 400 parts.

[0040] Polyurethane modified epoxy resin is prepared by the following method:

[0041] Put 1,4-butanediol diglycidyl ether in a three-necked flask according to the formula quantity, add ethylene glycol amine dropwise, raise the temperature to 85°C for 2 hours, add IPDI, add the catalyst dibutyltin dilaurate and react for 1 hour to obtain Epoxy resin whose side group contains -NCO group; add PPG400 and continue to react for 4 hours under the protection of nitrogen to obtain polyurethane modified epoxy resin.

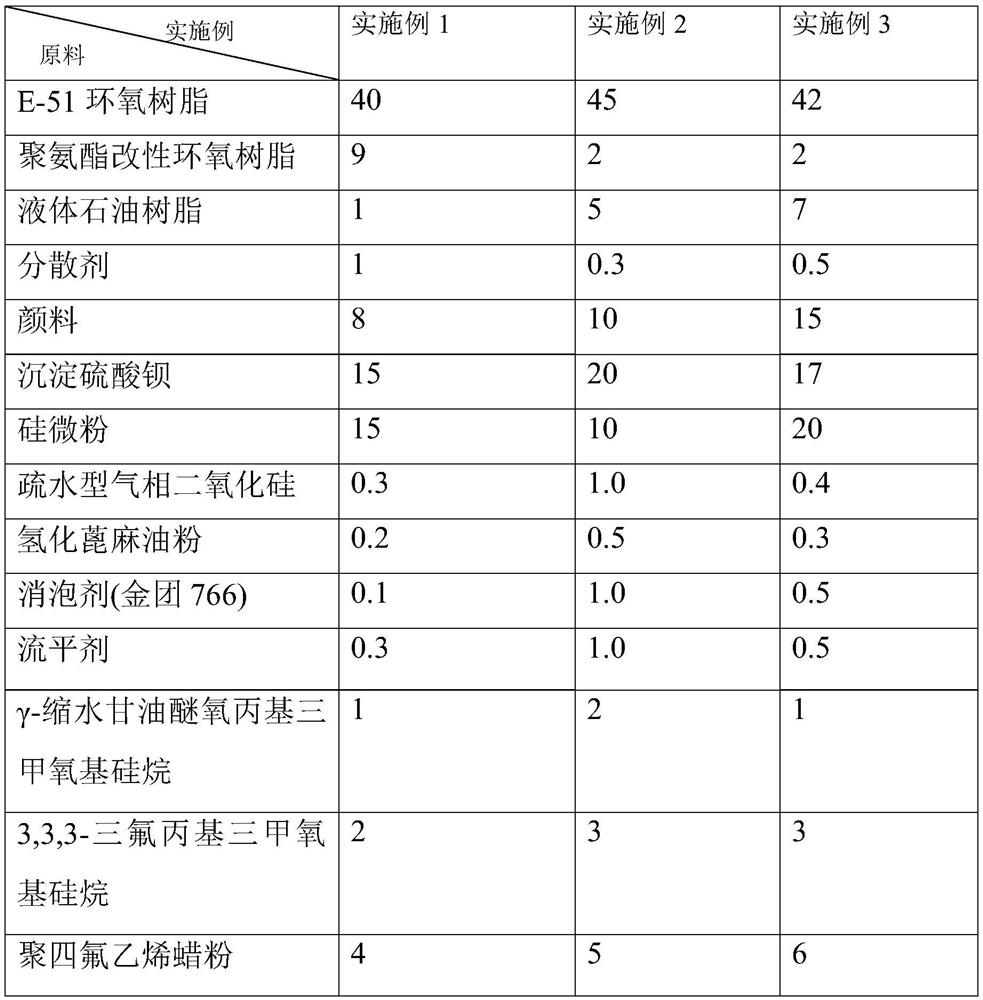

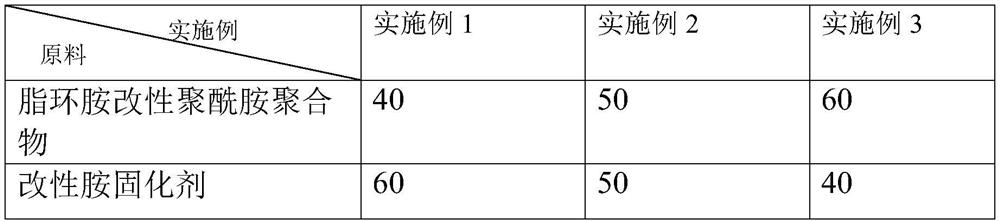

[0042] The weight composition of the raw material component A of the inner wall drag-reducing environmental protection coating of a long-distance pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com