High-toughness steel plate used in extremely cold environment and manufacturing method thereof

A manufacturing method and a technology in an extremely cold environment, applied in the field of steel plate and its manufacturing, can solve the problems of low efficiency, poor effect, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

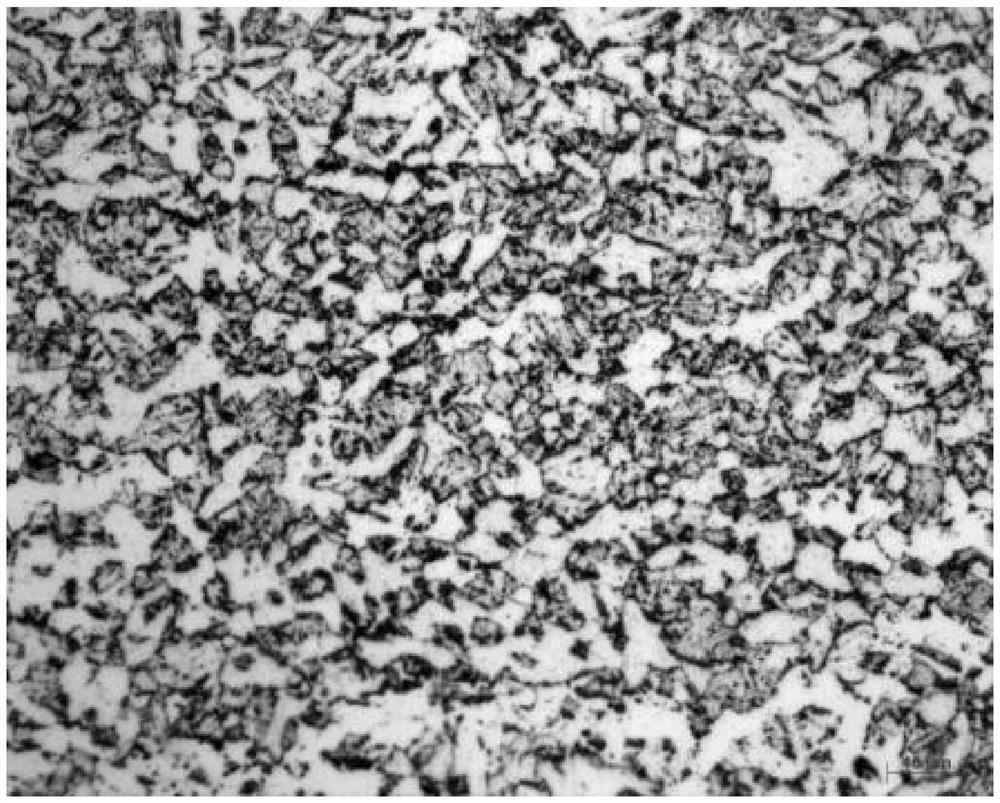

Image

Examples

Embodiment 1-7

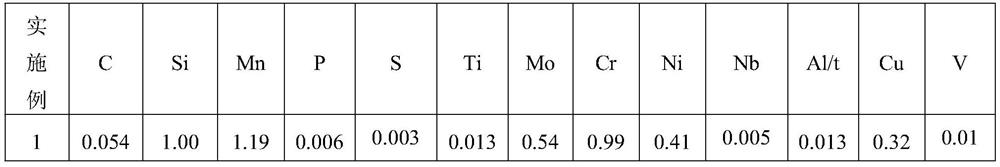

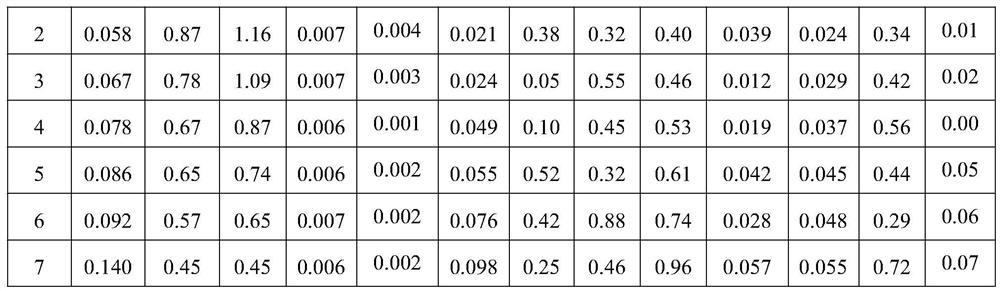

[0057] The high-toughness steel plate used under the extremely cold environment of the above-mentioned embodiments 1-7 is obtained by the following steps:

[0058] (1) Smelting and casting are carried out according to the chemical composition shown in Table 1.

[0059] (2) Heating: Heat the billet to 1000-1250°C, the billet heating and holding time is ≤1.5min / mm, the total heating and holding time is ≤450min, and the holding time at the high temperature section of 930°C-1250°C is ≤200min.

[0060] (3) Rolling: Control the final rolling temperature to ≥950°C, the reduction rate of each pass to be ≥8%, and air-cool to room temperature after rolling.

[0061] (4) Quenching + tempering: In the quenching step, heat to 830°C-930°C, the heating time is controlled at 1.2-1.5min / mm, and the heating time is not less than 30min, and water quenching is used to cool to below 300°C. Then air-cool; in the tempering step, heat to 530-690°C for a period of time, then air-cool. Among them, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com