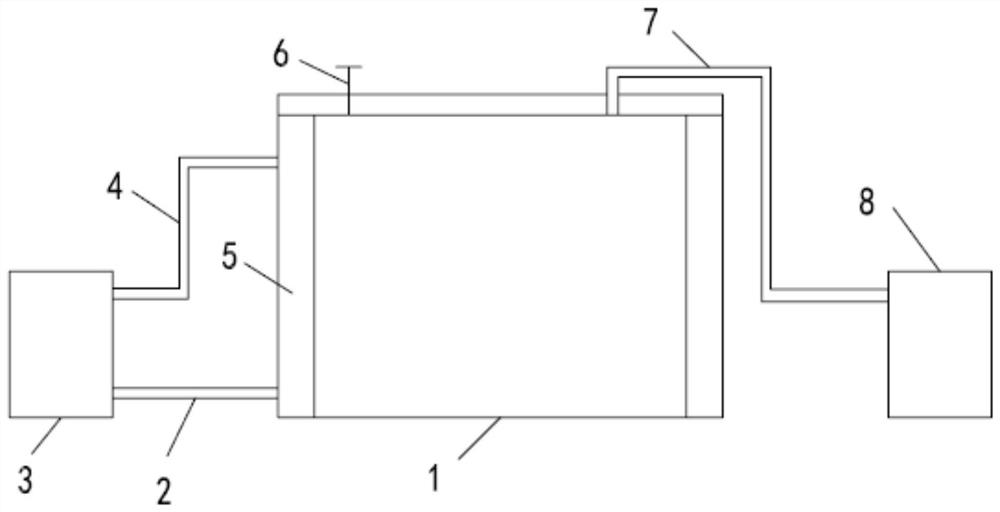

Method for bleaching pearls with sodium percarbonate and bleaching device

A technology of sodium percarbonate and pearls, applied in the field of jewelry handicrafts, can solve the problems of reducing the bleaching effect, corrosion, and the concentration of sodium percarbonate, etc., and achieve the effect of improving the bleaching effect, simple solution formula, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (control group 1)

[0036] 1. Take 100.00kg of seawater pearl grains (particle size greater than 7mm), and drill holes according to conventional jewelry pearls. Take 100.00kg of clean water at 0-4 degrees Celsius, put it into a 200-liter bleaching tank, start the ice water machine to automatically cool to 0-4 degrees Celsius, then add 3.0kg of sodium percarbonate, stir to dissolve completely, and then put in 100.00kg of already beaten Hole pearl grains, cover the bleach container lid, do not pressurize. After bleaching until the third day, turn off the ice water machine, deflate, and open the cover. Take out the pearls and soak them in clean water for 3-5 times, once a day. Then let it dry and that's it.

[0037] Effectiveness test: 1. Bleached pearls are tested according to the method stipulated in the national standard GB / T18781-2008. The gloss level of seawater pearls reaches grade A up to 1.00kg, and grade B reaches 26.00kg. There are 73.00kg of pear...

Embodiment 2

[0043] Embodiment 2 (control group 2)

[0044] 1. Take 100.00kg of low-grade seawater pearls (particle size greater than 7mm), and drill holes according to conventional jewelry pearls. Take 100.00kg of hydrogen peroxide solution (concentration 0.3%) and put it into a 200-liter bleaching tank, start the ice water machine to automatically cool to 0-4 degrees Celsius, then put 100.00kg of perforated pearls, cover the bleaching container cover, and start the emptying tank. The press is automatically pressurized to 1MPa. After bleaching until the third day, stop the chiller and air compressor, release the air through the pressure reducing valve, and open the cover. Take out the pearls and soak them in clean water for 3-5 times, once a day. Then let dry and that's it.

[0045]Effectiveness test: 1. Bleached pearls are tested according to the method stipulated in the national standard GB / T18781-2008. The luster level of seawater pearls reaches A grade up to 0.00kg, reaches B grade...

Embodiment 3

[0052] 1. Take 100.00kg of seawater pearl grains (particle size greater than 7mm), and drill holes according to conventional jewelry pearls. Take 100.00kg of clean water at 0-4 degrees Celsius, put it into a 200-liter bleach tank, start the ice water machine to automatically cool to 0-4 degrees Celsius, then add 3.00kg of sodium percarbonate, stir to dissolve completely, and then put 100.00kg of already Perforated pearls, covered with bleach container lid, airtight. Start the air compressor to automatically pressurize to 1MPa. After bleaching until the third day, stop the chiller and air compressor, deflate, and open the cover. Take out the pearls and soak them in clean water for 3-5 times, once a day. Then let it dry and that's it.

[0053] Effectiveness test: 1. Bleached pearls are tested according to the method stipulated in the national standard GB / T18781-2008. The luster level of seawater pearls reaches grade A up to 33.00kg, and grade B reaches 40.00kg, and 27.00kg ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com