Sample application machine, target plate inactivation device and target plate inactivation method

A technology of inactivation and target plate, which is applied in the direction of water supply equipment, preparation of test samples, sanitary equipment for toilets, etc., can solve the problems of affecting test results and low efficiency of manual spotting, so as to avoid cross-contamination and improve alcohol High utilization rate and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

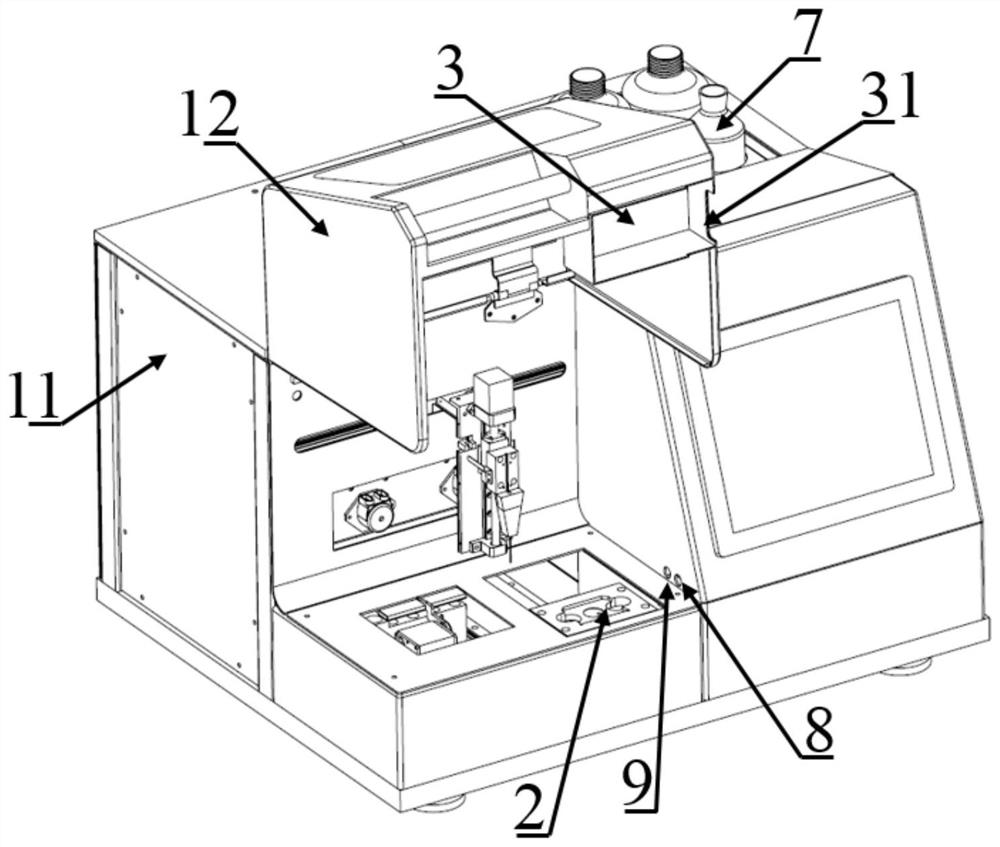

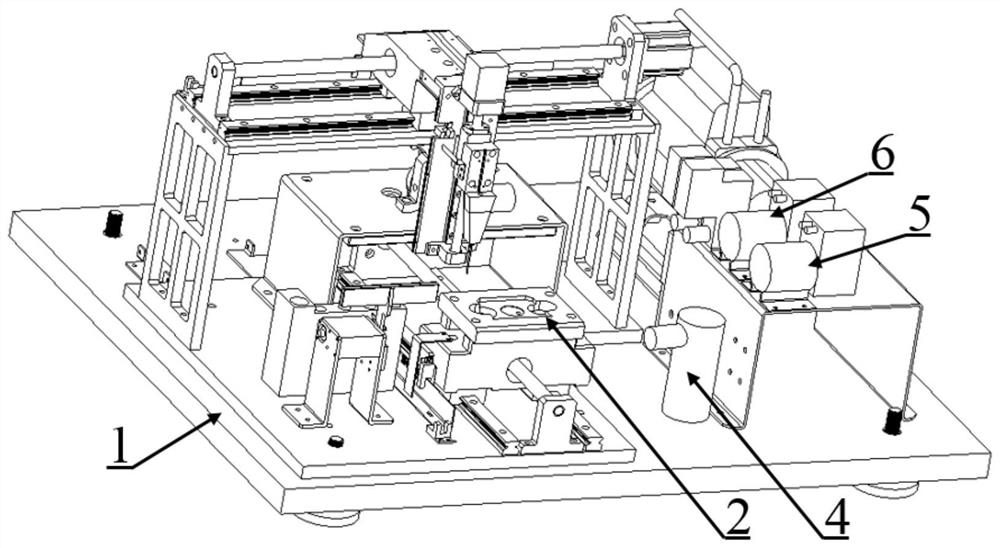

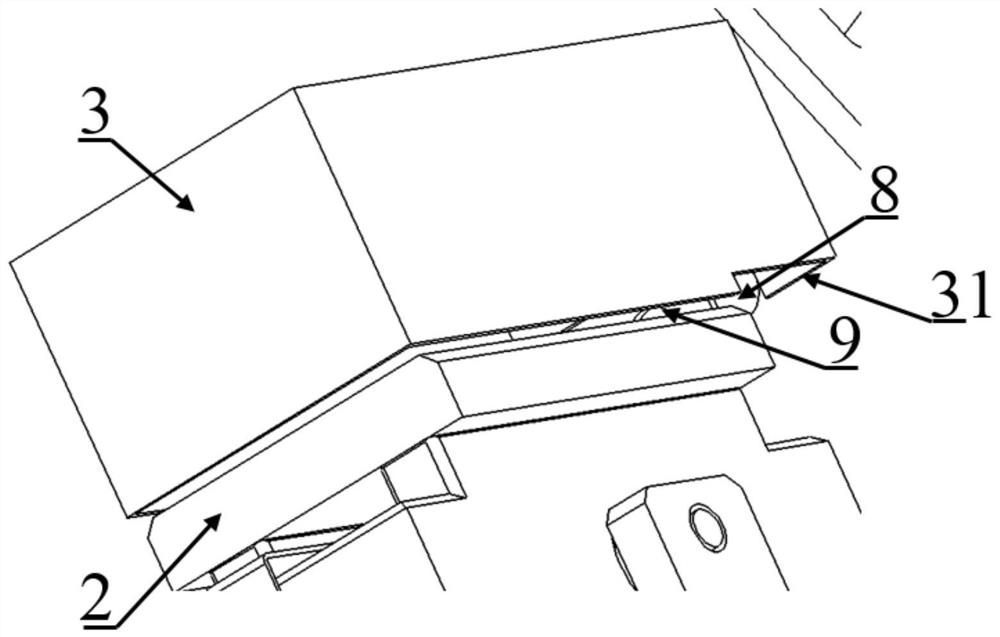

[0035] Such as figure 1 , figure 2 as well as image 3 As shown, the present invention provides a target plate inactivation device for spotting machine, including a frame 1, a housing 11, a hatch 12, a target groove 2 for installing a target plate, and a cover for covering the target groove 2. Sealing cover 3, gap 31, atomizer 4, No. 1 diaphragm pump 5, No. 2 diaphragm pump 6, exhaust gas treatment bottle 7, air inlet 8, air outlet 9. The casing 11, hatch 12, target slot 2, sealing cover 3, atomizer 4, exhaust gas treatment bottle 7, No. 1 diaphragm pump 5 and No. 2 diaphragm pump 6 are all installed on the frame 1, and the sealing cover 3 and the target slot 2 cooperate to form an inactivation space, and the air inlet 8 and the air outlet 9 are arranged on the wall of the inactivation space.

[0036] The target groove 2 is slightly larger than the target plate, and is used to place the target plate. Meanwhile, a magnet is also arranged in the groove to fix the target plat...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that only one diaphragm pump is included, and the diaphragm pump is connected with the exhaust gas treatment bottle 7 to provide power and drive the alcohol mist to move into the exhaust gas treatment bottle 7 through the sealing cover gap 31 and the air outlet 9 , because the diaphragm pump discharges the air or alcohol mist in the inactivation space, thereby controlling the airflow direction in the inactivation space, and at the same time, the atomizer 4 continuously generates mist, which will enter the inactivation space and be discharged from the air outlet 9 , can also fully inactivate the target plate. This embodiment can reduce one diaphragm pump and save cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com