Low-energy-consumption high-flux reverse osmosis membrane and preparation method and application thereof

A reverse osmosis membrane, high-flux technology, used in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reduced salt rejection, easy to fall off, difficult to prepare inorganic nanoparticles, etc., to achieve hydrophilic The effect of improved property, high hydrophilicity, and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The polysulfone supporting membrane prepared by the above method is adopted, and the reverse osmosis membrane is prepared by the following method:

[0058] (1) Prepare an aqueous phase solution with a mass concentration of 2.5 wt% m-phenylenediamine, 1 wt% sodium hydroxymethanesulfonate and 0.05% isopropanolamine, and stir at room temperature to completely dissolve it.

[0059] (2) Contact the polysulfone supporting membrane with the above-mentioned aqueous phase solution for 30s, remove excess water on the surface of the membrane, and then contact the organic phase solution containing 0.15wt% trimesoyl chloride and 0.16wt% tributyl phosphate for 30s, the interface polycondensation to form a polyamide composite film; wherein, the organic phase solvent is isopar G isoparaffin.

[0060] (3) After the composite membrane was drained vertically in the air for 1min, it was treated in hot air at 100°C for 6min; % citric acid aqueous solution for 2 minutes; finally rinse the c...

Embodiment 2-8

[0062] The cross-linked aromatic polyamide reverse osmosis membrane was prepared according to the method in Example 1, the only difference being the types and proportions of raw materials shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

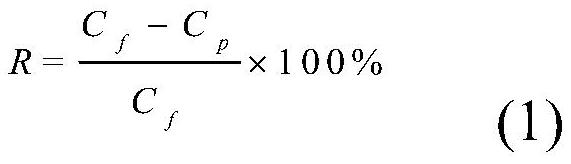

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com