Waste mango seed charcoal and preparation method thereof

A mango core and biochar technology, applied in the field of biomass resource utilization, can solve the waste of mango core and other problems, achieve the effects of reducing pollution, realizing resource utilization, and obvious performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

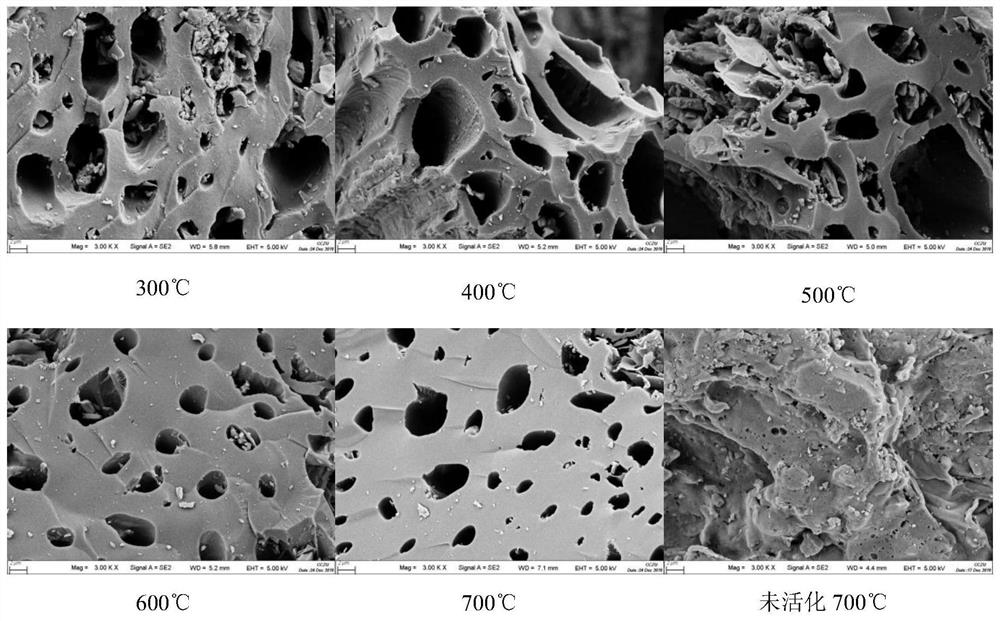

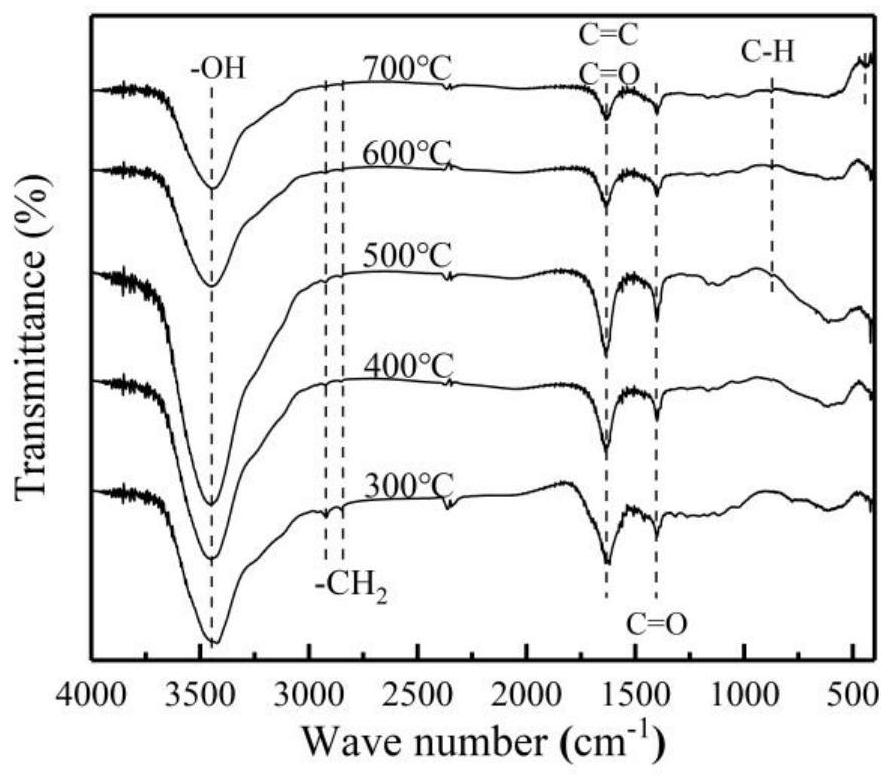

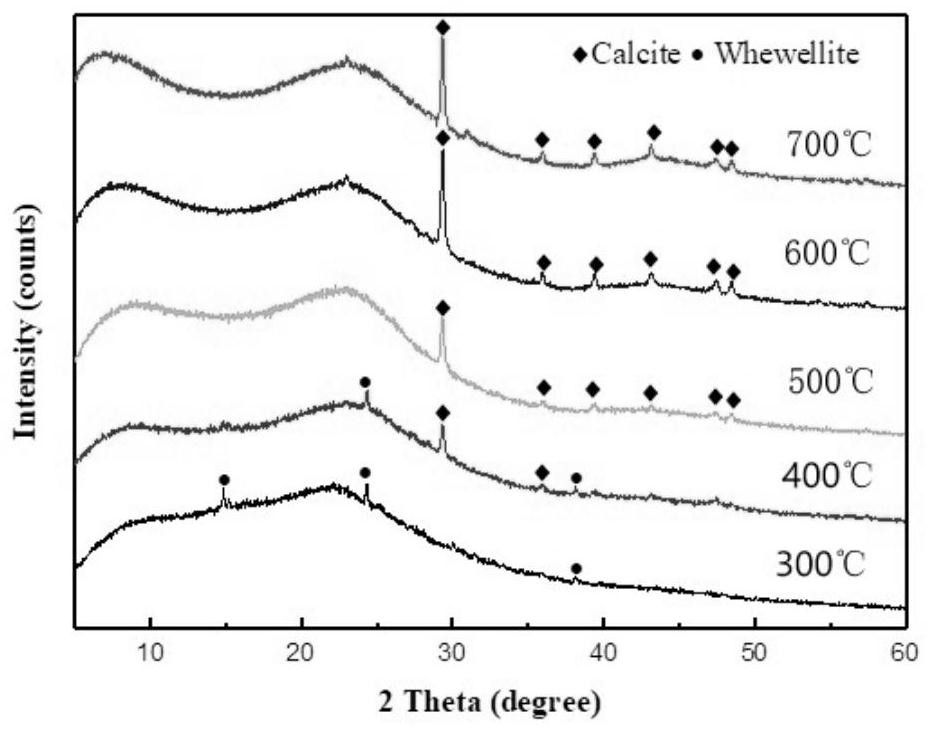

[0034] 10 g of mango core powder was placed in a tube furnace, the nitrogen atmosphere was turned on, the nitrogen gas flow rate was 30 mL / min, and then the temperature was raised to 300 °C for 2 h at a heating rate of 10 °C / min. After the carbonization is completed, take it out after cooling in the tube furnace, wash it with distilled water until it is neutral, filter and dry it to constant weight, grind it

experiment example 2

[0036] 10 g of mango core chips were placed in a tube furnace, the nitrogen atmosphere was turned on, and the nitrogen gas flow rate was 30 mL / min, and then the temperature was raised to 400 °C for 2 h at a heating rate of 10 °C / min. After the carbonization is completed, take it out after cooling in the tube furnace, wash it with distilled water to neutrality, then filter and dry it to constant weight, grind it through a 100-mesh sieve, dry it and store it for later use, that is, the mango kernel biochar is obtained. The yield of biochar is 35.42%.

Embodiment 3

[0038] 10 g of mango core chips were placed in a tube furnace, the nitrogen atmosphere was turned on, and the nitrogen gas flow rate was 30 mL / min, and then the temperature was raised to 500 °C for 2 h at a heating rate of 10 °C / min. After the carbonization is completed, take it out after cooling in the tube furnace, wash it with distilled water to neutrality, then filter and dry it to constant weight, grind it through a 100-mesh sieve, dry it and store it for later use, that is, the mango kernel biochar is obtained. The yield of biochar is 31.55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com