Solid propellant containing bimetallic oxide combustion accelerator and preparation method of solid propellant

A bimetallic oxide and solid propellant technology, which is applied in offensive equipment, explosive processing equipment, compressed gas generation, etc., can solve the problems that solid propellants cannot meet high burning rate and high energy release, and achieve strong catalysis and high The effect of thermal decomposition of ammonium chlorate exothermic, high explosive heat, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

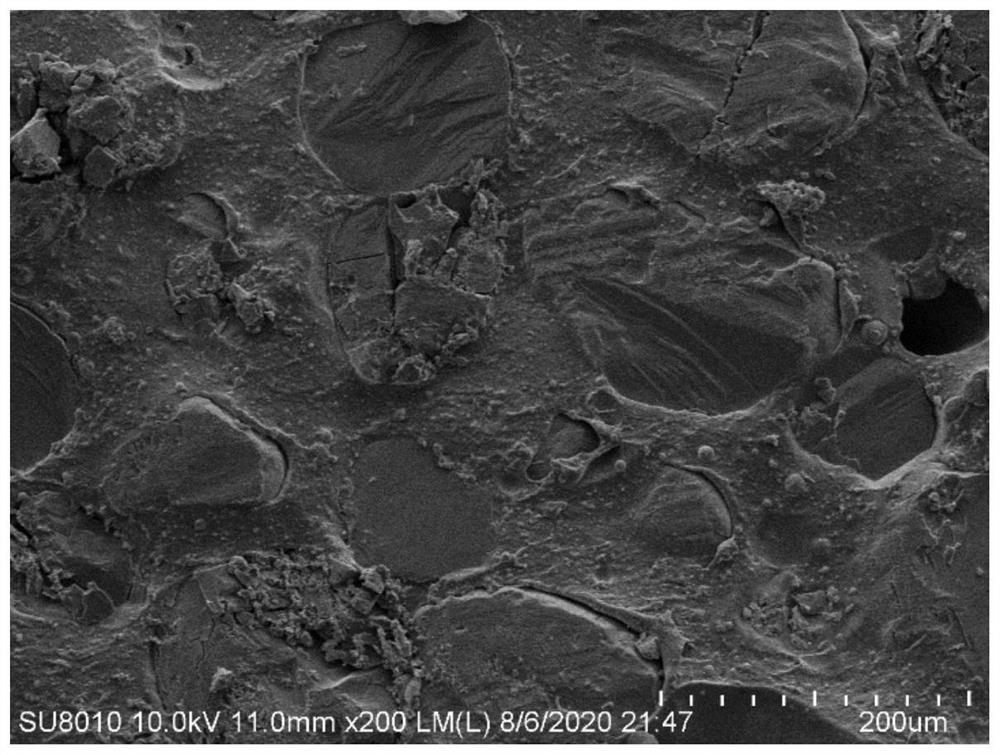

Image

Examples

specific Embodiment approach 1

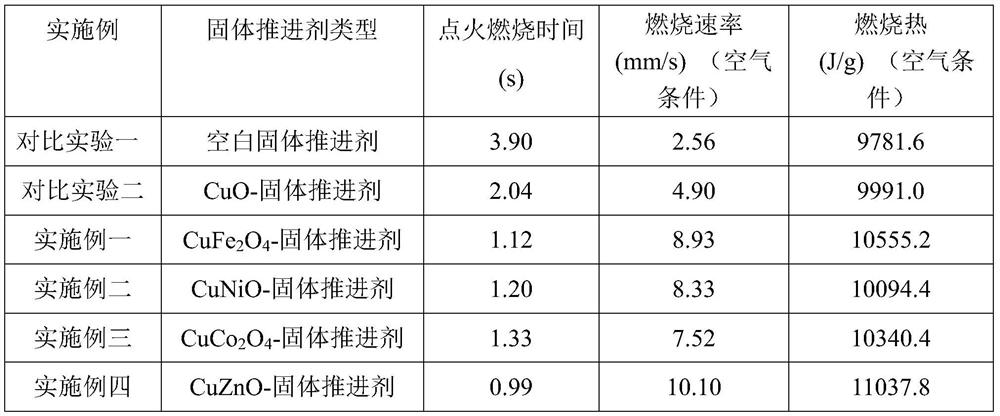

[0025] Specific embodiment one: a kind of solid propellant comprising bimetallic oxide burning rate agent described in this embodiment, it is by mass parts by 1~5 parts of bimetallic oxide burning rate agent, 60~80 parts Composed of oxidizing agent, 15-20 parts of metal fuel, 8-12 parts of binder, 0.5-3 parts of curing agent and 1-5 parts of plasticizer;

[0026] Described double metal oxide burning rate agent is CuZnO, CuCo 2 o 4 、CuFe 2 o 4 or CuNiO.

[0027] The CuZnO described in this embodiment is composed of CuO / ZnO composite, CuO and ZnO; the CuCo 2 o 4 by CuO / Co 3 o 4 Composite, CuO and Co 3 o 4 Composition; the CuFe 2 o 4 by CuO / Fe 3 o 4 Composite, CuO and Fe 3 o 4 Composition; the CuNiO is composed of CuO / NiO composite, CuO and NiO.

[0028] Due to the violent thermite reaction between metal oxides and aluminum powder, and the ability to effectively catalyze the decomposition reaction of ammonium perchlorate, it can significantly improve the combustio...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the described double metal oxide burning rate agent is prepared according to the following steps:

[0033] Dissolve copper nitrate trihydrate and metal salts in deionized water to obtain a mixed solution, and add NaOH and NaHCO dropwise to the mixed solution 3 aqueous solution until the pH of the mixed solution is 10-12, then stir for 4h-8h at a stirring speed of 300rpm-500rpm, and finally centrifuge, wash, filter and dry to obtain a dried solid; place the dried solid in In a muffle furnace at a temperature of 500°C to 800°C, calcining for 2h to 6h to obtain a double metal oxide burning rate agent;

[0034] The mol ratio of the copper ion in the copper nitrate trihydrate and the metal ion in the metal salt is 1: (0.2~5); Described NaOH and NaHCO 3 The concentration of NaOH in the aqueous solution is 0.02mmol / mL~0.05mmol / mL; the NaOH and NaHCO 3 NaHCO in aqueous solution 3 ...

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the metal salt is zinc nitrate hexahydrate, nickel acetate tetrahydrate, iron nitrate nonahydrate or cobalt nitrate hexahydrate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com