Continuous preparation process of phosphate flame retardant based on micro-channel reactor

A technology of microchannel reactor and preparation process, which is applied in chemical/physical/physical chemical reactors, phosphorus organic compounds, chemical instruments and methods, etc., and can solve the problems of high raw material input cost, incomplete reaction, and great pollution impact, etc. problem, to achieve the effects of short diffusion time, short reaction time and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

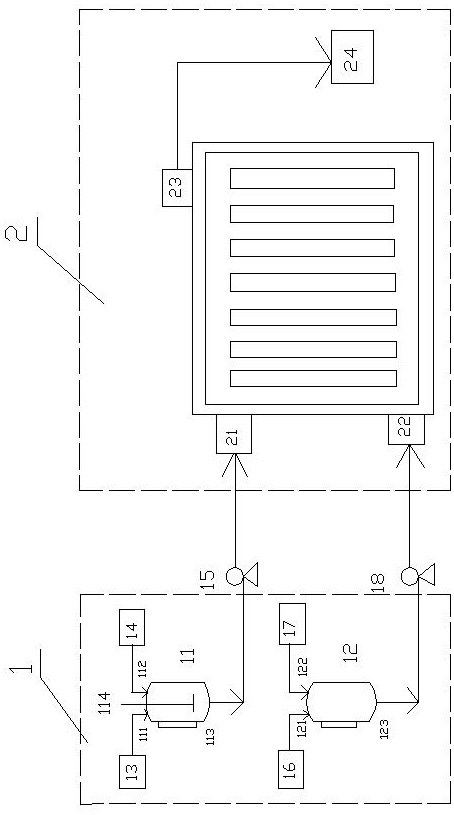

Method used

Image

Examples

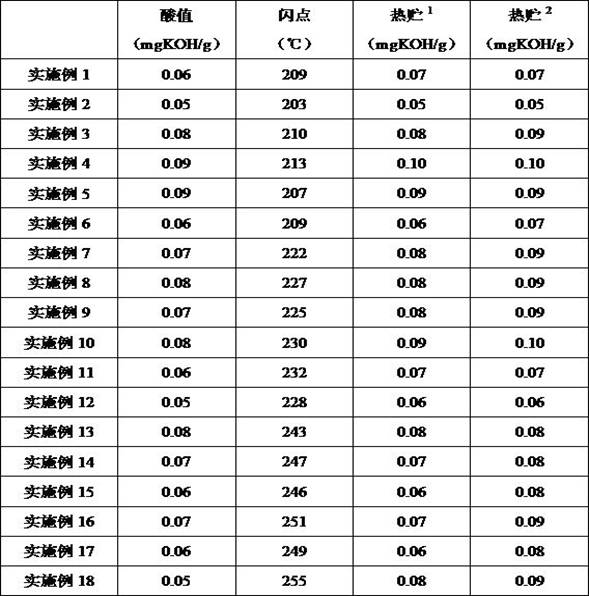

Embodiment 1

[0033] At room temperature, put 4.8mol of catalyst titanium tetrachloride and 1000mol of phosphorus oxychloride into the mixing raw material preparation tank and mix, and at the same time put 3000mol of propylene oxide into the epoxy compound metering tank.

[0034] The materials in the above two metering tanks were continuously poured into the microchannel reactor for reaction. The temperature in the reactor was maintained at 61° C., the pressure was 0.46 MPa, and the residence time was 10 minutes. TCPP was obtained by continuous discharge. The acid value of the product is 0.06mgKOH / g, and the yield is 99.92%.

Embodiment 2

[0036] At normal temperature, put 4.4mol of catalyst titanium tetrachloride and 1000mol of phosphorus oxychloride into the mixing raw material preparation tank and mix, and at the same time put 3006mol of propylene oxide into the epoxy compound metering tank.

[0037] The materials in the above two metering tanks were continuously poured into the microchannel reactor for reaction. The temperature in the reactor was maintained at 66° C., the pressure was 0.47 MPa, and the residence time was 9 minutes. TCPP was obtained by continuous discharge. The acid value of the product is 0.05mgKOH / g, and the yield is 99.93%.

Embodiment 3

[0039] At normal temperature, 3.1 mol of catalyst anhydrous tin tetrachloride and 1000 mol of phosphorus oxychloride are injected into the mixed raw material preparation tank for mixing, and at the same time, 3009 mol of propylene oxide is injected into the epoxy compound metering tank.

[0040] The materials in the above two metering tanks were continuously pumped into the microchannel reactor for reaction. The temperature in the reactor was maintained at 73° C., the pressure was 0.48 MPa, and the residence time was 9 minutes. TCPP was obtained by continuous discharge. The acid value of the product is 0.08mgKOH / g, and the yield is 99.93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com