Polyurethane foaming material and preparation method thereof

A foaming material, polyurethane technology, applied in applications, shoe soles, clothing, etc., can solve the problems of high material production cost, material residual isocyanate, high defective rate, etc., and achieve good economic feasibility, simple preparation method, and bubble cells even size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

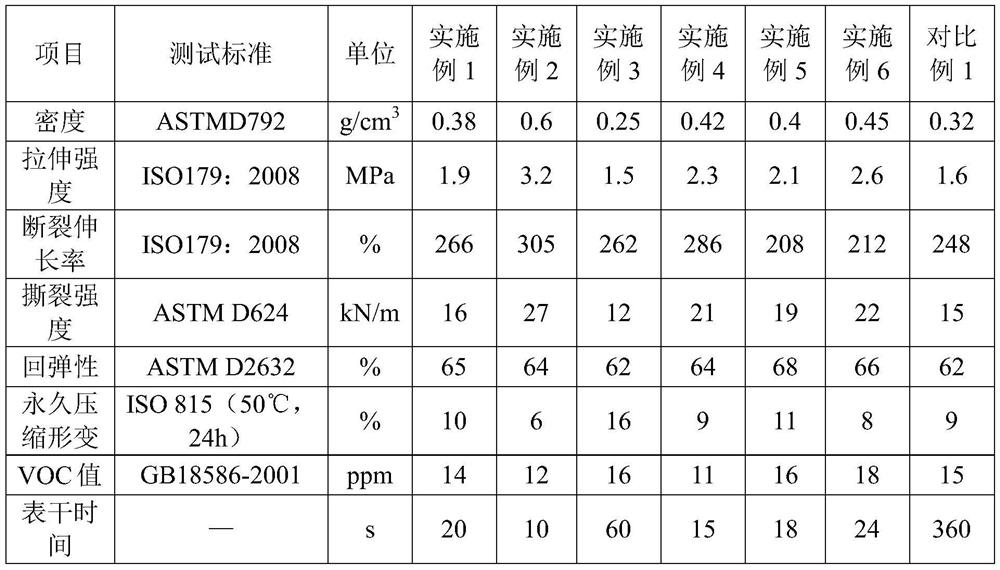

Examples

Embodiment 1

[0049] A: The thermoplastic polyurethane elastomer is uniformly added to the feed port of the twin-screw extruder with an aspect ratio of 60 in an amount of 50Kg / h through a weight loss balance, wherein the thermoplastic polyurethane elastomer is MDI-based and has a molecular weight of 1000g / mol. The thermoplastic polyurethane of tetrahydrofuran polyol system has a Shore hardness of 90A, and the temperature of the recrystallization peak is 90°C. 190°C, 170°C in the sixth, seventh, and eighth zones, 130°C in the ninth to fourteenth zones, screw speed 100rpm / min;

[0050] B: Take 100 parts by weight of isocyanate-terminated polyurethane, 1 part by weight of antioxidant 1010 and 1 part by weight of UV absorber UV328 and mix evenly, and then use a meterable hot-melt adhesive machine (temperature setting 100 ° C) to glue the above The mixture is evenly added to the feed port of the ninth zone of the twin-screw extruder with an aspect ratio of 60 in an amount of 50kg / h; 3 parts by w...

Embodiment 2

[0054] A: The thermoplastic polyurethane elastomer is uniformly added to the feeding port of the twin-screw extruder with an aspect ratio of 60 in an amount of 50Kg / h through a weight loss balance, wherein the thermoplastic polyurethane elastomer is MDI-based and has a molecular weight of 2000g / mol. The thermoplastic polyurethane of tetrahydrofuran polyol system has a Shore hardness of 60A, and the temperature of the recrystallization peak is 50°C. 140°C, 120°C for the sixth, seventh, and eighth zones, 100°C for the ninth to fourteenth zones, screw speed 80rpm / min;

[0055] B: Take 100 parts by weight of isocyanate-terminated polyurethane, 2 parts by weight of antioxidant 1010 and 1.5 parts by weight of UV absorber UV328 and mix evenly, and then use a meterable hot-melt glue machine (temperature setting 70 ° C) to put the above The mixture is evenly added to the feeding port of the sixth zone of the twin-screw extruder with an aspect ratio of 60 in an amount of 22kg / h; 1 part ...

Embodiment 3

[0059] A: The thermoplastic polyurethane elastomer is uniformly added to the feed port of the twin-screw extruder with an aspect ratio of 60 in an amount of 50Kg / h through a weight loss balance, wherein the thermoplastic polyurethane elastomer is MDI-based and has a molecular weight of 1800g / mol. The thermoplastic polyurethane of tetrahydrofuran polyol system has a Shore hardness of 88A, and the temperature of the recrystallization peak is 118°C. 220°C, 180°C for the sixth, seventh, and eighth zones, 150°C for the ninth to fourteenth zones, screw speed 120rpm / min;

[0060] B: Take 100 parts by weight of isocyanate-terminated polyurethane, 4 parts by weight of antioxidant 1010 and 3 parts by weight of UV absorber UV328 and mix evenly, and then use a meterable hot-melt glue machine (temperature setting 150 ° C) to glue the above The mixture is evenly added to the feed port of the seventh zone of the twin-screw extruder with an aspect ratio of 60 in an amount of 115kg / h; 6 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com