Solvent-free polyurethane coating and preparation method thereof

A solvent-free polyurethane and solvent-free technology, applied in the field of coatings, can solve the problems of high VOC value and poor coating effect, and achieve the effect of zero VOC content, excellent coating ability and high environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The second aspect of the embodiment of the present application provides a method for preparing a solvent-free polyurethane coating. The method for preparing the first component includes the following steps:

[0048] S01. The solvent-free hydroxyacrylic resin and the reactive diluent are subjected to the first mixing treatment to obtain the first mixture;

[0049] S02. The first mixture and the pigment are subjected to the second mixing treatment, and then the grinding treatment is carried out to the second mixture;

[0050] S03. The second mixture and the auxiliary agent are subjected to a third mixing treatment to obtain the first component.

[0051] The preparation method of the solvent-free polyurethane coating provided by the second aspect of the present application is simple and convenient, and only needs to mix the raw materials of the first component, and then mix it with the second component during use; The preparation method is simple in operation and convenie...

Embodiment 1

[0062] Solvent Free Polyurethane Coatings

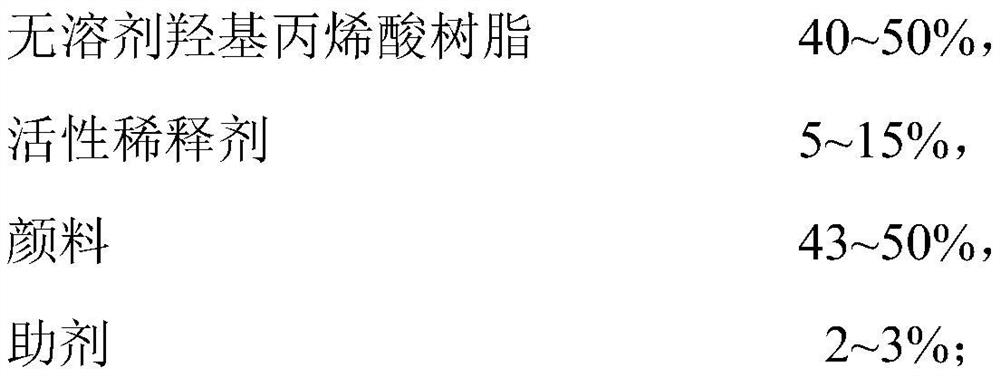

[0063] The solvent-free polyurethane coating includes the first component and the second component, and the total weight of the first component is 100%, including the following components in the following weight percentages:

[0064]

[0065] The second component includes an isocyanate curing agent;

[0066] Wherein, the mass ratio of the first component and the second component is 4:1;

[0067] The solvent-free hydroxy acrylic resin is selected from the solvent-free hydroxy acrylic resin S5800 provided by Zhanchen Company,

[0068] The reactive diluent is selected from D-290 produced by Vertellus Performance Materials Company of the United States,

[0069] The pigment is selected from the mixture of 30wt% colored pigment and 13wt% extender pigment by weight percentage, the colored pigment is selected from titanium dioxide, and the extender pigment is selected from barium sulfate precipitation,

[0070] The auxiliary agent is ...

Embodiment 2

[0080] Solvent Free Polyurethane Coatings

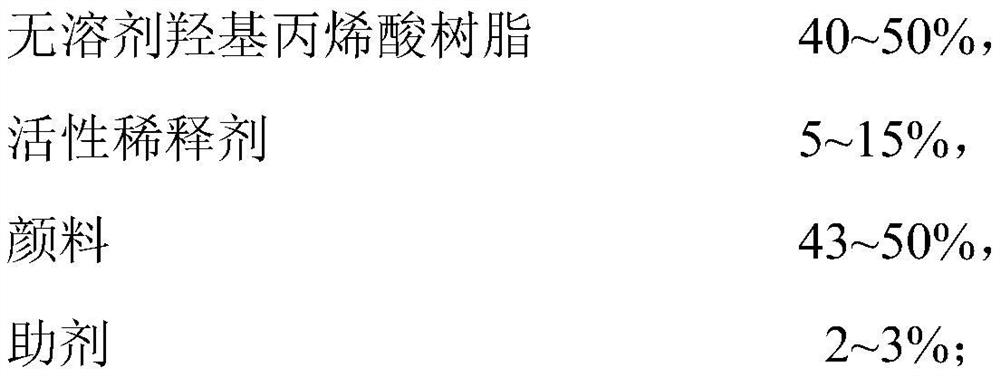

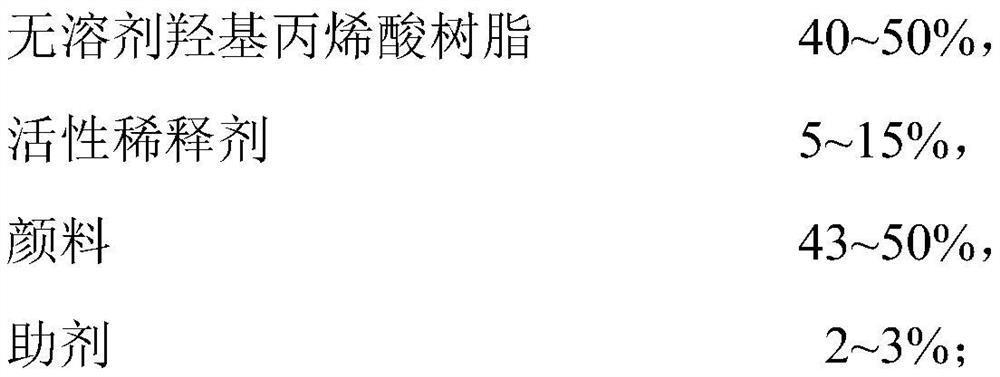

[0081] The solvent-free polyurethane coating includes the first component and the second component, and the total weight of the first component is 100%, including the following components in the following weight percentages:

[0082]

[0083] The second component includes an isocyanate curing agent;

[0084] Wherein, the mass ratio of the first component and the second component is 4:1;

[0085] The solvent-free hydroxy acrylic resin is selected from the solvent-free hydroxy acrylic resin S5800 provided by Zhanchen Company,

[0086] The reactive diluent is selected from D-290 produced by Vertellus Performance Materials Company of the United States,

[0087] The pigment is selected from a mixture of 30wt% colored pigments and 18wt% extender pigments by weight, the colored pigment is selected from titanium dioxide, and the extender is selected from barium sulfate precipitation,

[0088] The auxiliary agent is selected from the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com