Preparation method of electronic ammonia gas sensor based on non-covalent monatomic layer graphene

A single atomic layer graphite and ammonia sensor technology, applied in the field of sensors and nanomaterials, can solve the problems of low selectivity and sensitivity, hinder application, poor stability, etc., and achieve good sensitivity and selectivity, good stability and The effect of service life and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, preparing a graphene device with a field effect transistor structure

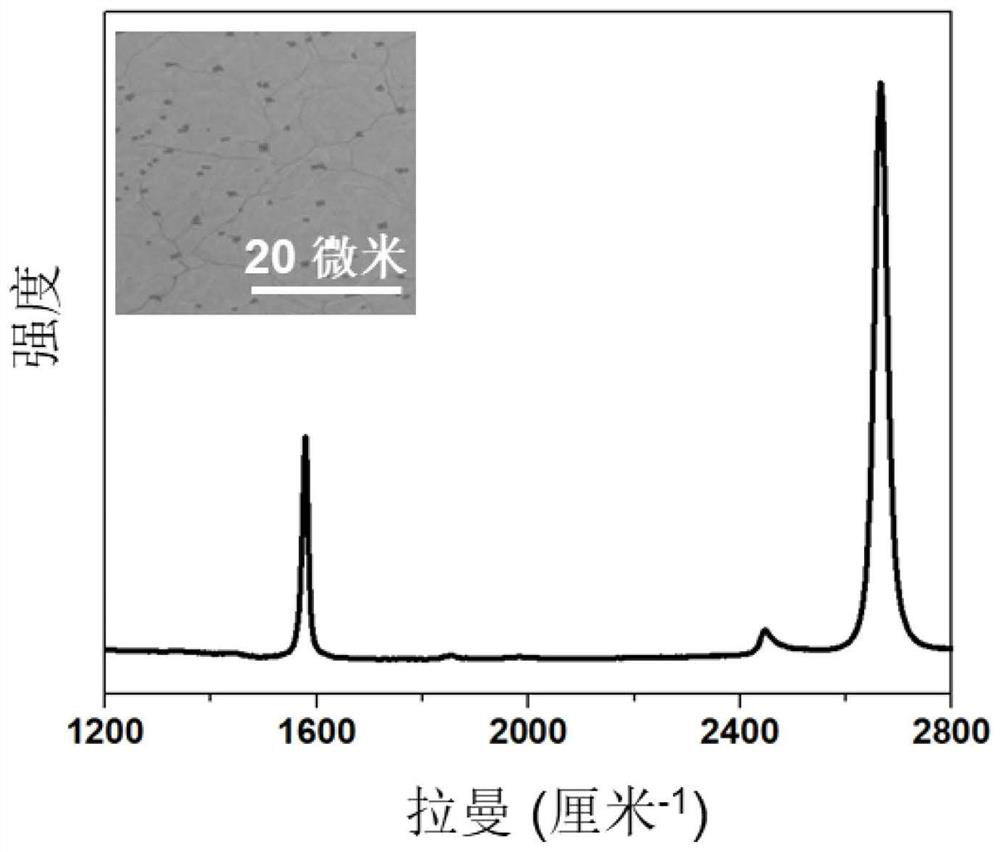

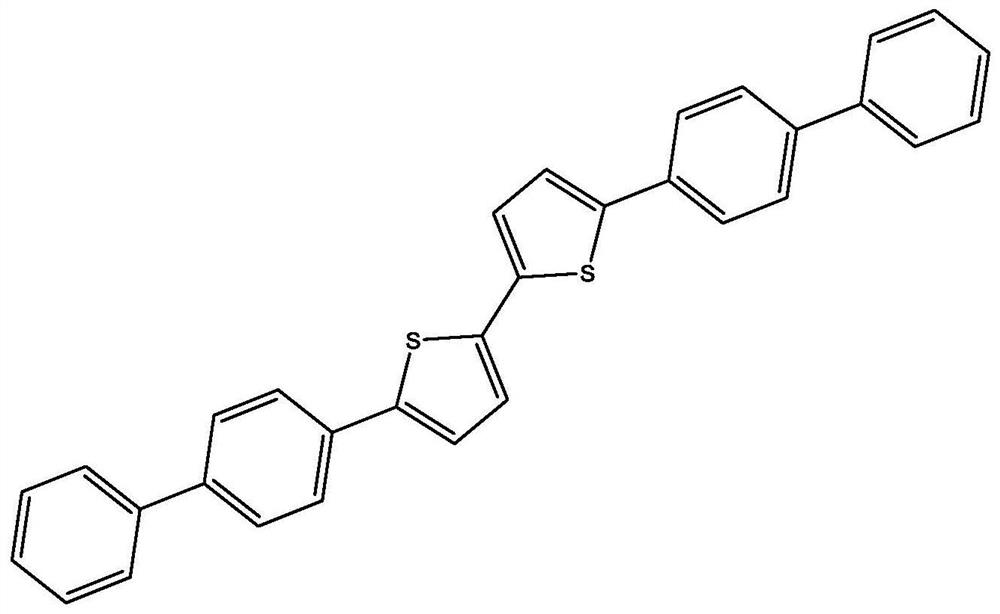

[0038] Using existing electron beam lithography and oxygen plasma etching techniques to fabricate graphene ribbons from chemical vapor deposited single-layer graphene, figure 1 The scanning electron microscope image and the Raman spectrogram of single-layer graphene are provided, and the substrate material of graphene is silicon dioxide and silicon (see image 3 ), with a gate electrode on the substrate. The source and drain electrodes of the graphene ribbons are then prepared using existing electron beam lithography and metal deposition methods, thereby realizing the electrical linkage of the graphene ribbons. Graphene ribbons with source, drain, and gate electrodes constitute a graphene device with a field-effect transistor structure. The electrode material is metallic gold with a thickness of 70 nanometers. Graphene ribbons act as channels with dimensions of 40 microns in length and 10 ...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is that in step 3, the graphene device having a field effect transistor structure is immersed in the BP2T molecular solution for 2 hours.

[0049] The ammonia gas sensor test of the electronic ammonia gas sensor obtained in this embodiment shows that the ammonia gas response time is 250 seconds, and the recovery time of the gas sensor to the initial state is 200 seconds without any additional treatment. Depend on Figure 8 It can be seen that the electronic gas sensor obtained with an immersion time of 2 hours has the highest sensitivity, which is three times that of intrinsic graphene. Since the intrinsic graphene ammonia sensitivity is 1ppm, the obtained electronic ammonia sensor based on non-covalent functionalized single atomic layer graphene has a sensitivity of 300ppb level.

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is:

[0052] The graphene ribbons prepared in step 1 have a length of 50 microns and a width of 50 microns.

[0053] The electrode material gold in step 1 has a thickness of 120 nanometers.

[0054] In step 2, the mass volume ratio of BP2T to toluene is 1:2, and 7 mg of BP2T powder is dissolved in 14 ml of toluene.

[0055] Step 3 is to immerse the graphene device with the field effect transistor structure in the BP2T molecular solution for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com