Negative electrode active material, and preparation method and application thereof

A negative electrode active material, nano-silicon technology, applied in the direction of negative electrodes, nanotechnology for materials and surface science, active material electrodes, etc., can solve the problem of easy stacking of Mxene materials, affecting the performance of composite materials, and poor point-surface contact to achieve excellent mechanical properties, promote de-embedding and embedding, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Another embodiment of a method for preparing a negative electrode active material, the process flow chart of the preparation method can be found in Figure 5 , the method includes the following steps S100-S300:

[0088] Step S100: preparing lamellar Mxene material

[0089] Specifically, the preparation method of the lamellar Mxene material is: the Mxene material is mixed with an organic polymer solvent, and the layer expansion treatment is performed to obtain the lamellar Mxene material;

[0090] In this embodiment, the Mxene material is expanded to obtain a lamellar Mxene material with a low number of layers, which is beneficial to the surface layer adhesion of nano-silicon;

[0091] In some embodiments, the preparation method also includes the step of ultrasonic dispersion after layer expansion treatment; layer expansion and ultrasonic dispersion can even obtain a layered Mxene material with good dispersion, and the composite combination with nano-silicon has a good ...

Embodiment 1

[0147] (1) The ceramic phase precursor MAX raw material (Ti 3 AlC 2 ) immersed in the HCl+LiF mixed etchant for stirring etching, the stirring time is 15min, the stirring rate is 800rpm, the mass volume ratio of LiF and HCl is 1:15g / mL, the addition amount of the ceramic phase precursor MAX The mass ratio to LiF is 1:1.05 to obtain Mxene material;

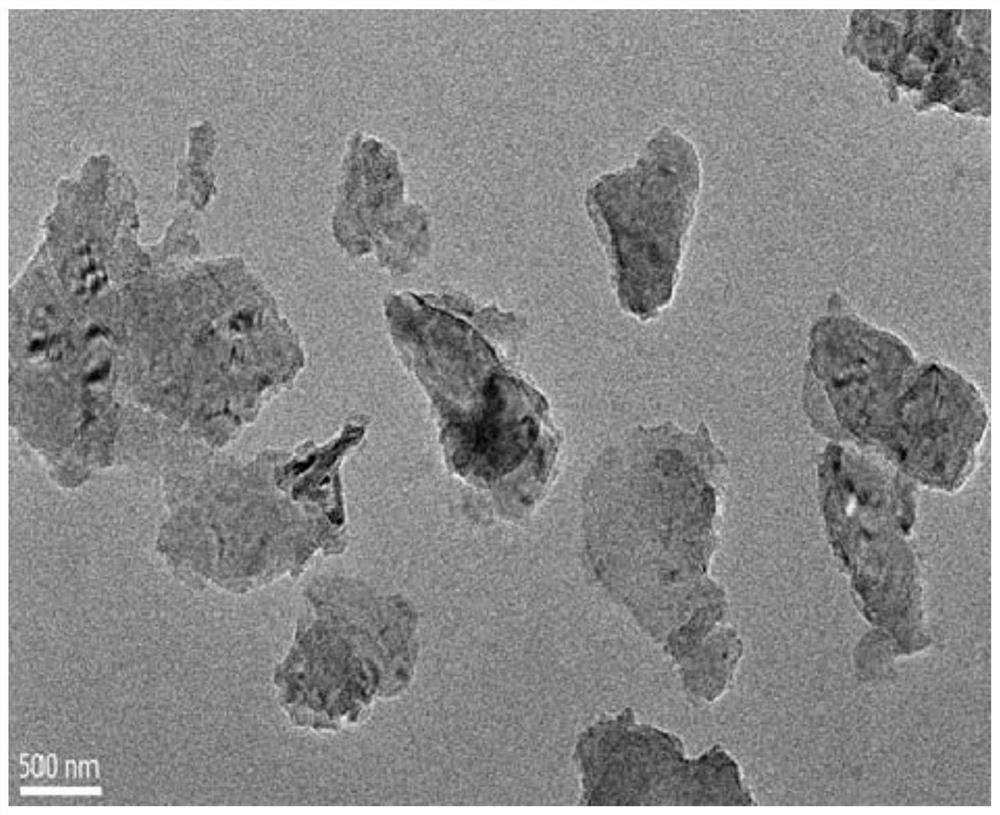

[0148] (2) The Mxene material is added in a mixed solvent of chloroform and ethanol, wherein chloroform: the mass ratio of ethanol is 10:1, and the mass ratio of the Mxene material to chloroform is 0.5:5, using a stirrer to stir, stirring frequency Be 30Hz, stirring time 2h, then add deionized water and carry out the ultrasonic treatment that frequency is 15Hz, the mass ratio of described Mxene material and deionized water is 1:20, ultrasonic time is 5h, obtains lamellar Mxene material; The number of sheets of the lamellar Mxene material is a single layer;

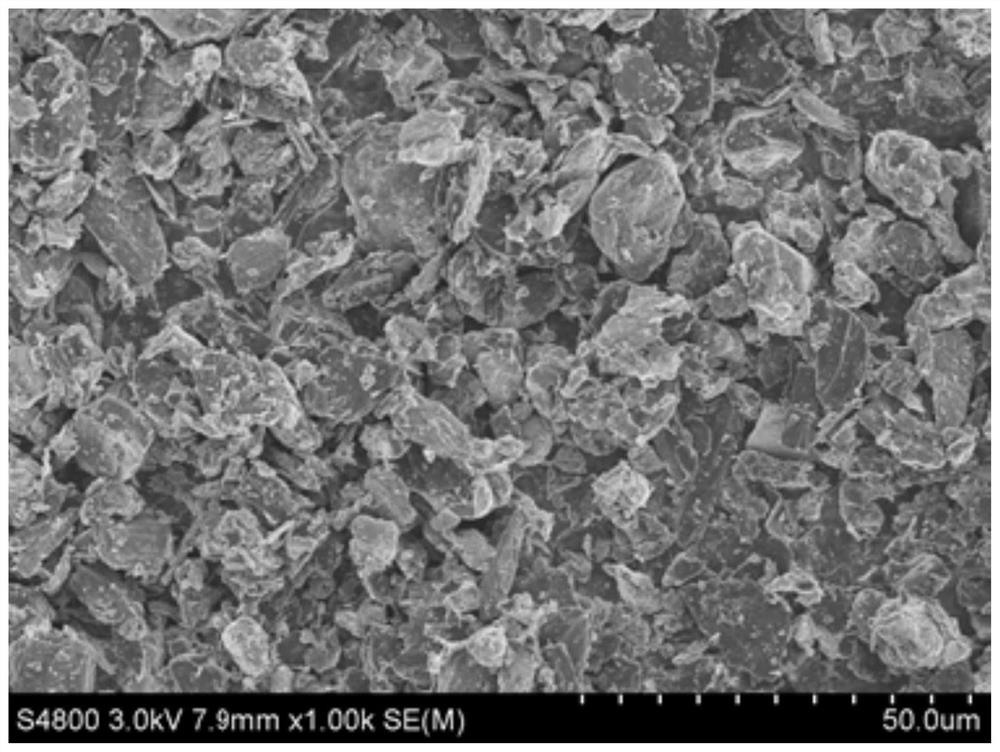

[0149] (3) The purity is 99.9%, the median particle diameter is 50nm, a...

Embodiment 2

[0155] (1) The ceramic phase precursor MAX raw material (Ti 3 AlC 2 ) immersed in the HCl+LiF mixed etchant for stirring etching, the stirring time is 5min, the stirring rate is 200rpm, the mass volume ratio of LiF and HCl is 1:10g / mL, the addition amount of the ceramic phase precursor MAX The mass ratio with LiF is 1:1.05, and the Mxene material is obtained;

[0156] (2) Add the obtained Mxene material to a mixed solvent of chloroform and ethanol, wherein chloroform: the mass ratio of ethanol is 1:5, the mass ratio of the Mxene material to chloroform is 1:8, and the stirring frequency is 30Hz for 3h , then add deionized water and carry out ultrasonic treatment with a frequency of 15Hz, the mass ratio of the Mxene material to deionized water is 1:20, and the ultrasonic time is 5h to obtain the lamellar Mxene material; the lamellar Mxene material The average number of layers is 5 layers;

[0157] (3) The purity is 99.9%, the median particle diameter is 30nm, and the specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com