Anti-crystallization additive, preparation method and application of anti-crystallization additive in boiler SCR denitration

An anti-crystallization agent and additive technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as crystallization, poor surface insulation effect, and large operation risks, so as to reduce energy consumption and use less Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

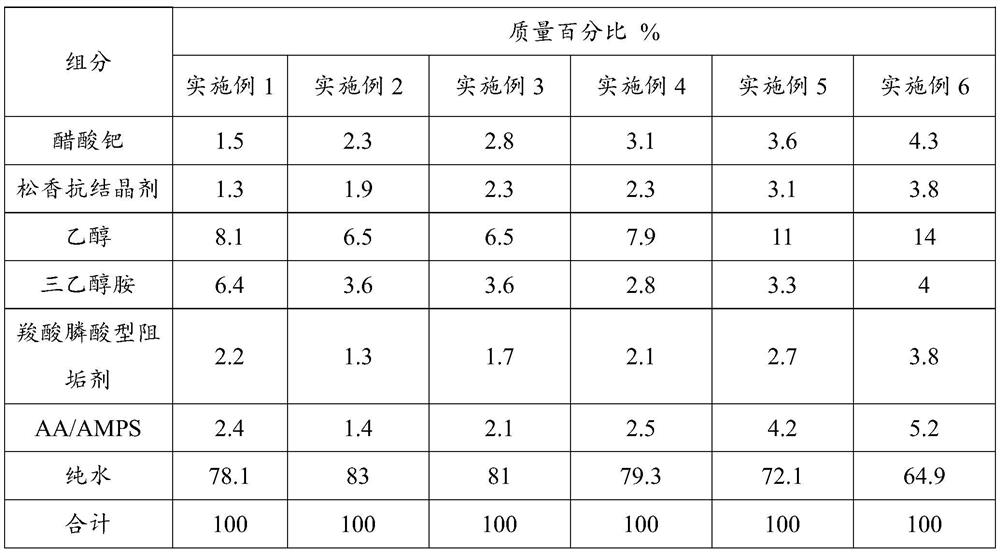

[0022] Another embodiment of the present invention provides a method for preparing an anti-crystallization additive. The raw materials are mixed and heated to 65-75°C for reaction to obtain the primary product 1 of the additive, and the primary product 1 is heated to 45-55°C. Enter ammonia gas to react to obtain the additive primary product 2, and filter the additive primary product 2 to obtain the anti-crystallization additive; the raw materials include the following components according to mass percentages, palladium acetate 1-5%, rosin anti-crystallization agent 1-4%, ethanol 8-15%, triethanolamine 2-7%, carboxylic acid phosphonic acid scale inhibitor 1-4%, AA / AMPS 1-6%, and the balance is water.

[0023] In some examples of this embodiment, the temperature is heated to 65-75° C., and the reaction is kept for 10-20 minutes.

[0024] In some examples of this embodiment, the time for feeding ammonia gas to carry out the reaction is 40-60 minutes.

[0025] In some examples of...

Embodiment 1

[0032] 1. Add palladium acetate, rosin anti-crystallization agent, ethanol, triethanolamine, carboxylic acid phosphonic acid scale inhibitor, AA / AMPS, and pure water in a mass ratio of 1.5:1.3:8.1:6.4:2.2:2.4:78.1 In the dissolving tank, mix and stir, then raise the temperature to 70° C., keep the temperature for 15 minutes, and prepare the additive primary product 1.

[0033] 2. Put the primary additive product 1 into the reactor, heat it to 50°C, feed ammonia into the reactor, and then keep stirring for 50 minutes to prepare the primary additive product 2.

[0034] 3. Filter and purify the additive primary product 2 through a mechanical filter with a filtration accuracy of 5 microns to make the additive finished product.

Embodiment 2

[0036] 1. Add palladium acetate, rosin anti-crystallization agent, ethanol, triethanolamine, carboxylic acid phosphonic acid scale inhibitor, AA / AMPS, and pure water in a mass ratio of 2.3:1.9:6.5:3.6:1.3:1.4:83 respectively In the dissolving tank, mix and stir, then raise the temperature to 70° C., keep the temperature for 15 minutes, and prepare the additive primary product 1.

[0037] 2. Put the primary additive product 1 into the reactor, heat it to 50°C, feed ammonia into the reactor, and then keep stirring for 50 minutes to prepare the primary additive product 2.

[0038] 3. Filter and purify the additive primary product 2 through a mechanical filter with a filtration accuracy of 5 microns to make the additive finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com