A nitrogen oxide generation system

A technology of nitrogen oxides and generating systems, applied in nitrogen compounds, gas generating devices, chemical/physical processes, etc., can solve problems such as corrosion of devices and pipelines, serious problems, difficulty in long-term stable operation of devices, etc., and achieve full utilization of raw materials , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

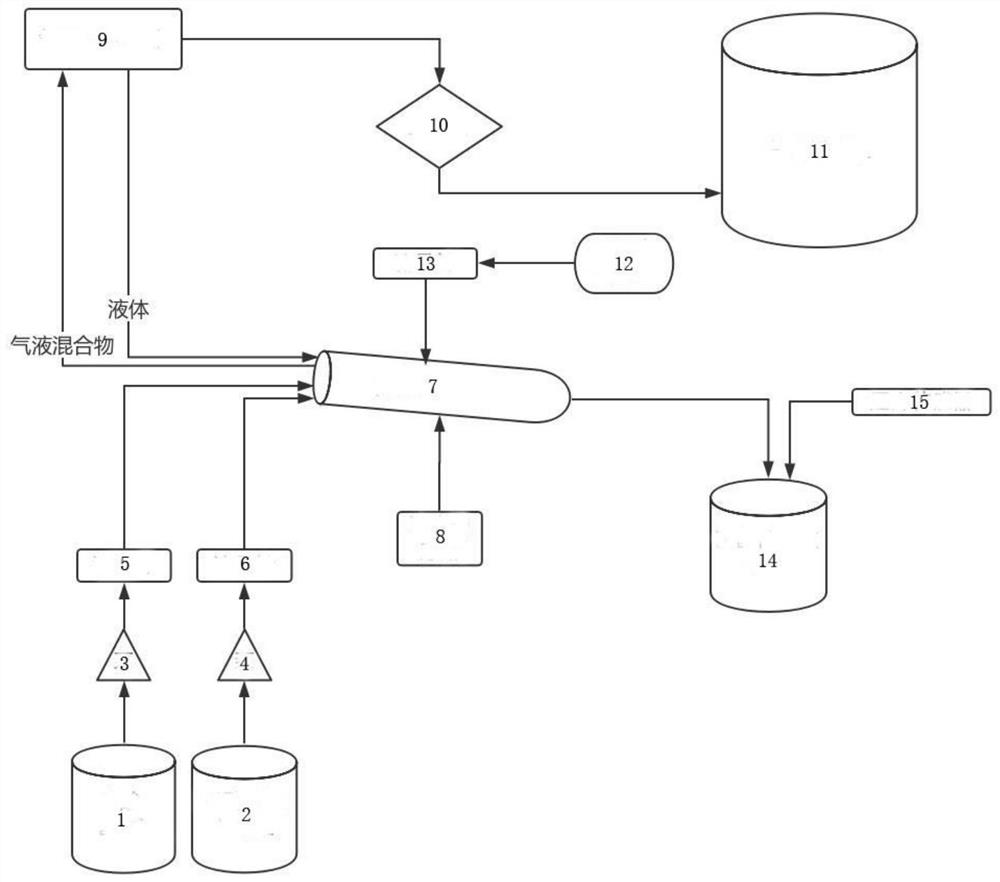

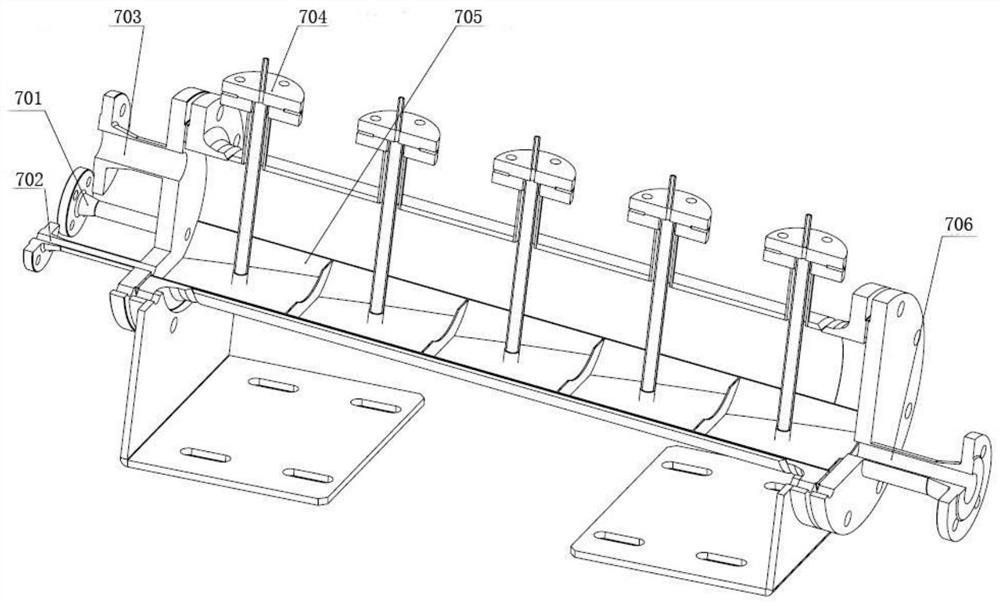

[0048] Establishment figure 1 , figure 2 The nitrogen oxide generated system shown, wherein the nitrogen oxide generator 7 has a diameter of 200 mm, length 1450mm, a total of 7-level plate, and an external design of an electric heating belt, a material liquid inlet and an exit flange, and air drums in each stage .

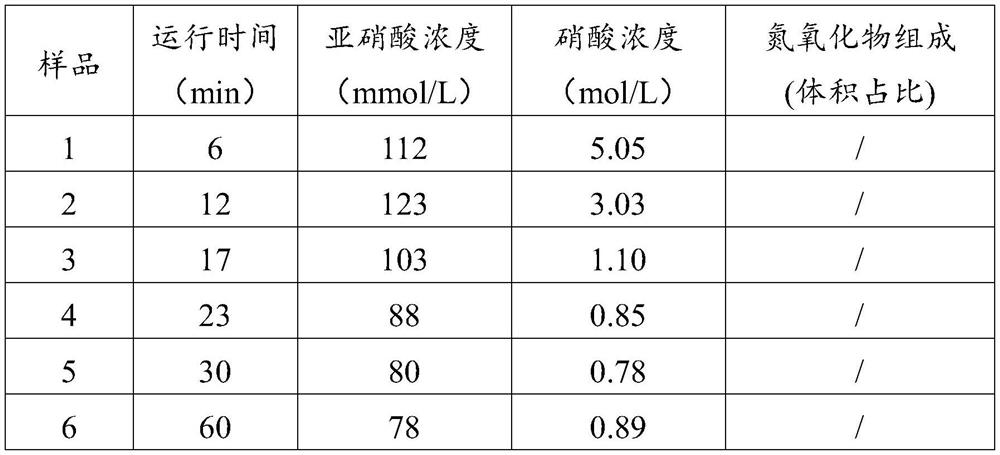

[0049] A nitrogen oxide preparation experiment was carried out based on the established nitrogen oxide generated system. The resulting nitrogen oxide was analyzed by a nitrogen oxide concentration analysis system, and the prepared nitrogen oxide finally was absorbed with sodium hydroxide saturated solution.

[0050] The nitrogen oxide generating system operation process conditions:

[0051] Nitric acid concentration 10mo / L, sodium nitrite concentration 4mol / L, air flow 4.2m 3 / h, run time 4h.

[0052] First, heating nitric acid, sodium nitrite, and nitrogen oxide generators to 70 ° C, and then simultaneously open the two binders and compressed air feeds. The react...

Embodiment 2

[0058] The nitrogen oxide generating system is in Example 1.

[0059] The nitrogen oxide generating system operation process conditions:

[0060] Nitric acid concentration 12mo / L, sodium nitrite concentration 6 mol / L, air flow 4.2m 3 / h, run time 4h.

[0061] First, the nitric acid, nitrite solution and nitrogen oxide generator are first heated to 70 ° C, and then simultaneously open the two branches and compressed air feed, and the reflective fluid flows to the sodium nitrate solution collecting tank 14, resulting nitrogen oxidation The material gas is stored until the supercharged pump is boosted to a nitrogen oxide gas buffer tank 11. The pressure of the buffer tank gradually increases. When the buffer tank pressure is increased to 0.15 MPa (this value can be set by itself), the nitrogen oxide outlet valve is started, and the nitrogen oxide gas is discharged, the discharged nitrogen oxide gas is buffered. After absorption of sodium hydroxide solution. When the pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com