A fluidized bed device for preparing uranium nitride and method of using the same

A fluidized bed, uranium nitride technology, applied in the field of nuclear engineering, can solve the problems of less research on special equipment, and achieve the effect of thorough exhaust gas disposal and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

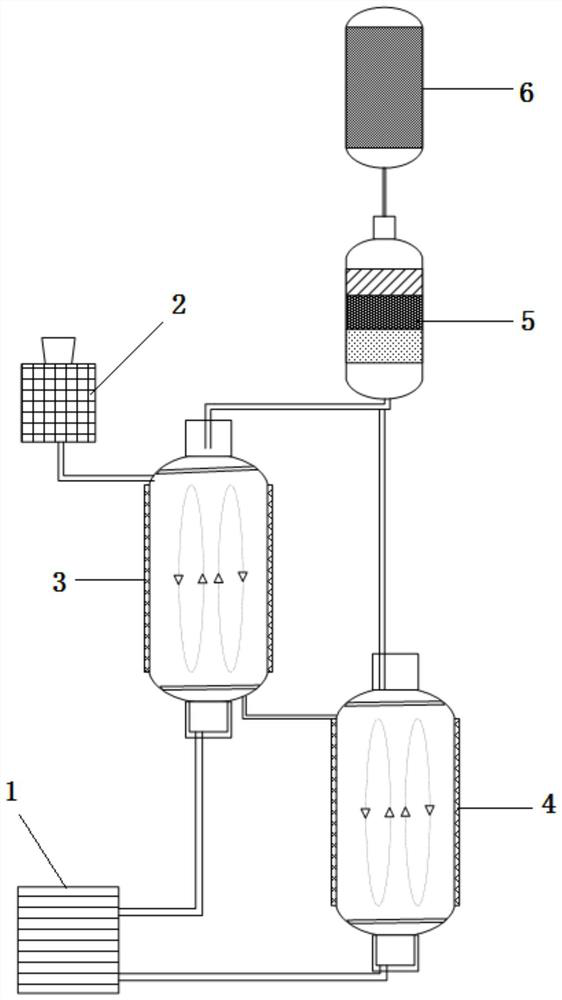

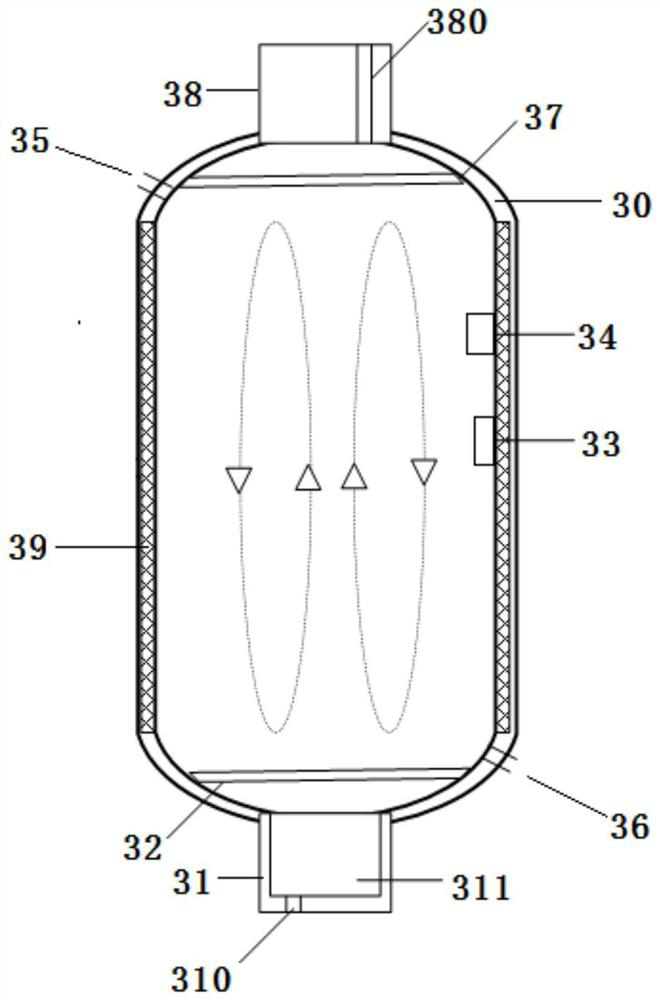

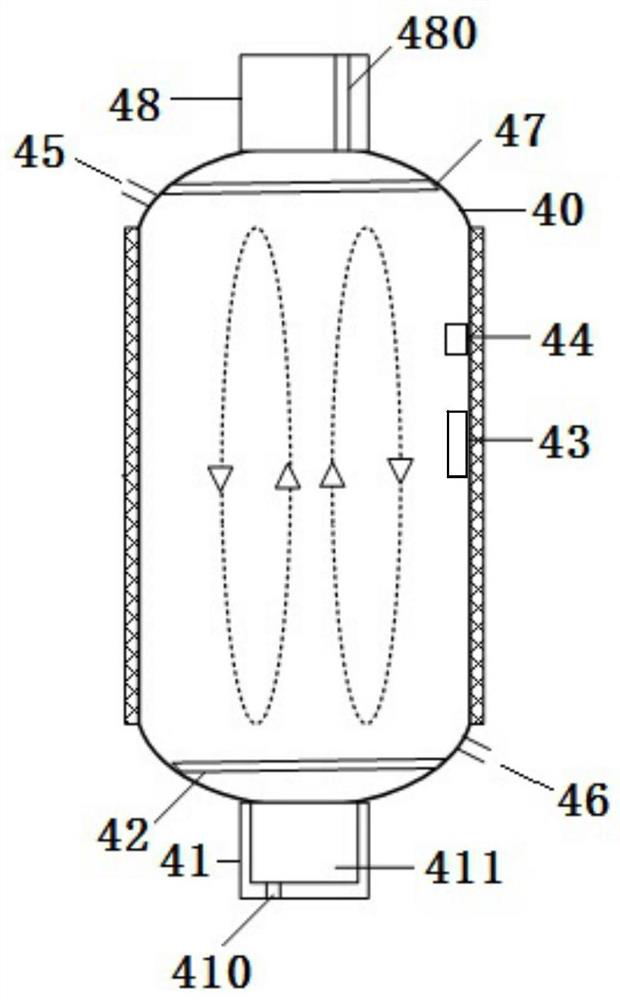

[0031] A fluidized bed device for preparing uranium nitride, comprising a gas system 1, a material mixing system 2, a low temperature fluidized bed 3, a high temperature fluidized bed 4, a tail gas treatment device 5 and an absorption tower 6; the gas system 1 It is connected with the low temperature fluidized bed 3 and the high temperature fluidized bed 4 respectively, the mixing system 2 is connected with the low temperature fluidized bed 3, the low temperature fluidized bed 3 is connected with the high temperature fluidized bed 4, and the low temperature fluidized bed 3. The high temperature fluidized bed 4 is respectively connected with the tail gas treatment device 5 , and the tail gas treatment device 5 is connected with the absorption tower 6 .

[0032] In this example, the reaction steps are controlled to be carried out in a low-temperature fluidized bed and a high-temperature fluidized bed respectively, so as to ensure the smooth progress of the reaction under differen...

Embodiment 2

[0046] In order to achieve the above purpose, the present embodiment also provides a method for using a fluidized bed device for preparing uranium nitride, comprising the following steps:

[0047] S1, UO 2 with NH 4 HF 2 In molar ratio 1:4~1:8 or U 3 O 8 with NH 4 HF 2 At a molar ratio of 1:12 to 1:24, put it into a mixing device, and mix and grind in the mixing device for 30-60 minutes to obtain ground powder particles;

[0048] S2. Pour argon into the low-temperature fluidized bed, and repeat the cleaning 3 times;

[0049] S3, the ground powder particles after mixing and grinding are transferred to the low temperature fluidized bed, heated to 20-125 ° C by the first heating device and the first temperature control sensor, and reacted for 3-12 hours to obtain the reaction product;

[0050] S4, transfer the reaction product to the high temperature fluidized bed, pass Ar, NH 3 , N 2 , H 2 The combined gas mixture is heated to 700-1000 ℃ by the second heating device an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com