High-concentration pharmaceutical wastewater treatment method

A technology for pharmaceutical wastewater and treatment methods, which is applied in water/sewage treatment, natural water treatment, special compound water treatment, etc. It can solve the problems of high concentration of suspended solids, complex pharmaceutical wastewater components, and various types of organic matter, and achieve faster flocculation. The effect of sedimentation rate, shortening separation time, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for treating high-concentration pharmaceutical wastewater, comprising the following steps:

[0033] Step 1. Grille filtration: the high-concentration pharmaceutical wastewater is treated by coarse and fine grid decontamination machines to remove larger impurities and suspended solids;

[0034] Step 2. Acid analysis-flocculation: pass the pharmaceutical wastewater treated by the grid into the adjustment tank, add sulfuric acid to adjust the pH to 2.5, stir to mix evenly, and when the emulsion appears in the solution, add flocculant to it, stir, and statically Placement and separation; the flocculant is ferric chloride, and the dosage is 3kg / t;

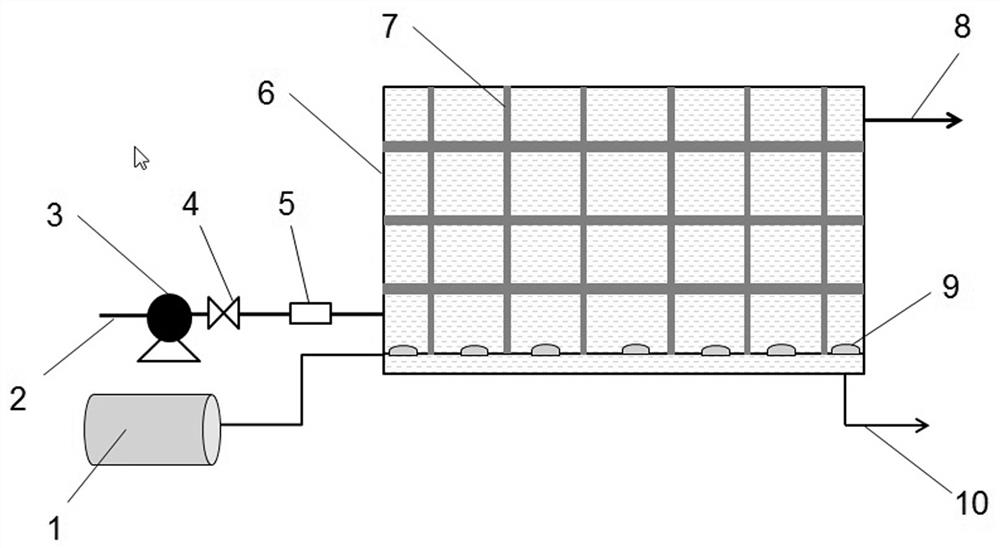

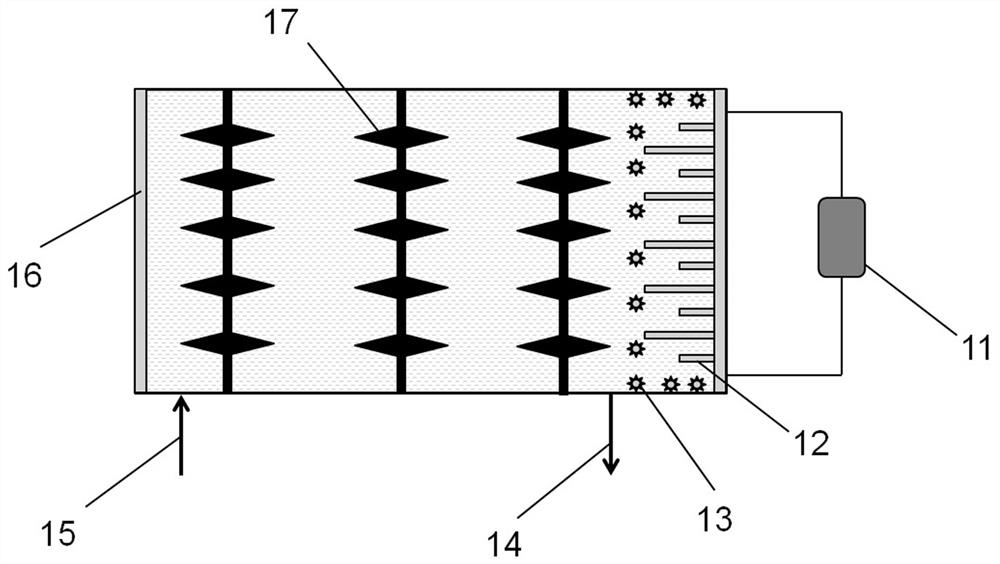

[0035] Step 3, iron-carbon micro-electrolysis-electric Fenton combined treatment: the supernatant of step 2 gained is passed into iron-carbon micro-electrolysis reactor ( figure 1 shown), reacted for 0.8h, and then the iron-carbon micro-electrolysis effluent was passed into the electric Fenton reaction cell for 0.5h; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com