Sludge dehydration conditioning method based on protein denaturant

A protein denaturant, protein denaturation technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. The effect of promoting coagulation, effectively improving sludge dewatering performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

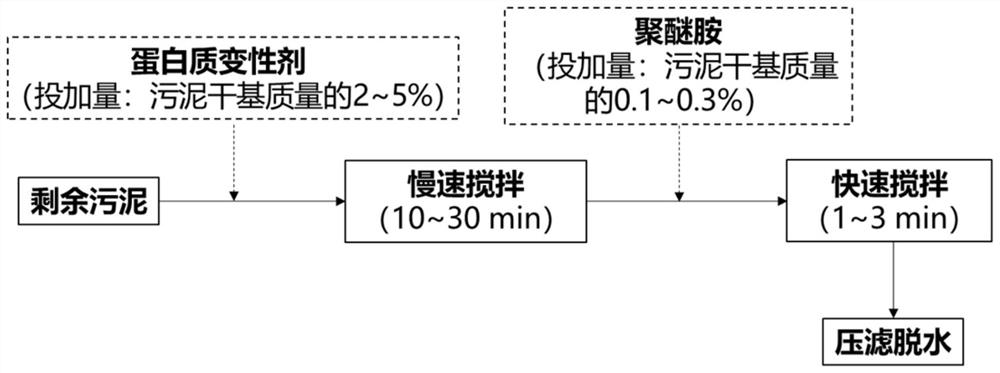

[0028] 1. Protein denaturants are used in sludge dehydration conditioning:

[0029] In this embodiment, the sludge in a certain urban sewage treatment plant in Shanghai is used as the treatment object, and a protein denaturant-based sludge dehydration conditioning method is used to treat it. The method includes the following steps:

[0030] 1) mixing tannin extract, furfural, and glutaraldehyde in a mass ratio of 5:5:1 to prepare a protein denaturant;

[0031] 2) Add a protein denaturant to the above sludge, the amount of which is 2% of the dry weight of the sludge, and then fully react for 30 minutes under the condition of 300rpm magnetic stirring, and reduce the hydrophilicity of the extracellular protein through protein complexation and denaturation , reduce the overall water holding capacity of sludge flocs, and obtain pretreated sludge;

[0032] 3) Add a protein emulsifying coagulant (polyether amine) to the pretreated sludge in an amount of 0.1% of the dry weight of the...

Embodiment 2

[0038] 1. Protein denaturants are used in sludge dehydration conditioning:

[0039] In this embodiment, the unconditioned raw sludge in Example 1 is used as the treatment object, and it is treated with a protein denaturant-based sludge dehydration conditioning method, which includes the following steps:

[0040] 1) mixing tannin extract, furfural, and glutaraldehyde with a mass ratio of 10:10:1 to prepare a protein denaturant;

[0041]2) Add a protein denaturant to the above sludge, the amount of which is 5% of the dry weight of the sludge, and then fully react for 10 minutes under the condition of 100rpm magnetic stirring, and reduce the hydrophilicity of the extracellular protein through protein complexation and denaturation , reduce the overall water holding capacity of sludge flocs, and obtain pretreated sludge;

[0042] 3) Add a protein emulsifying coagulant (polyetheramine) to the pretreated sludge, the amount of which is 0.3% of the dry weight of the sludge, and then s...

Embodiment 3

[0046] 1. Protein denaturants are used in sludge dehydration conditioning:

[0047] In this embodiment, the unconditioned raw sludge in Example 1 is used as the treatment object, and it is treated with a protein denaturant-based sludge dehydration conditioning method, which includes the following steps:

[0048] 1) mixing tannin extract, furfural, and glutaraldehyde with a mass ratio of 7.5:7.5:2 to prepare a protein denaturant;

[0049] 2) Add a protein denaturant to the above sludge, the amount of which is 3.5% of the dry weight of the sludge, and then fully react for 20 minutes under the condition of 200rpm magnetic stirring, and reduce the hydrophilicity of the extracellular protein through protein complexation and denaturation , reduce the overall water holding capacity of sludge flocs, and obtain pretreated sludge;

[0050] 3) Add a protein emulsifying coagulant (polyetheramine) to the pretreated sludge, the amount of which is 0.2% of the dry weight of the sludge, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com