Preparation method and application of MOF material with adjustable proton conduction performance

A proton conduction and MOF technology, applied in the field of MOF materials and their preparation, can solve the problems of low-cost production and high price of unfavorable materials, and achieve the effect of accelerating application and promotion and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

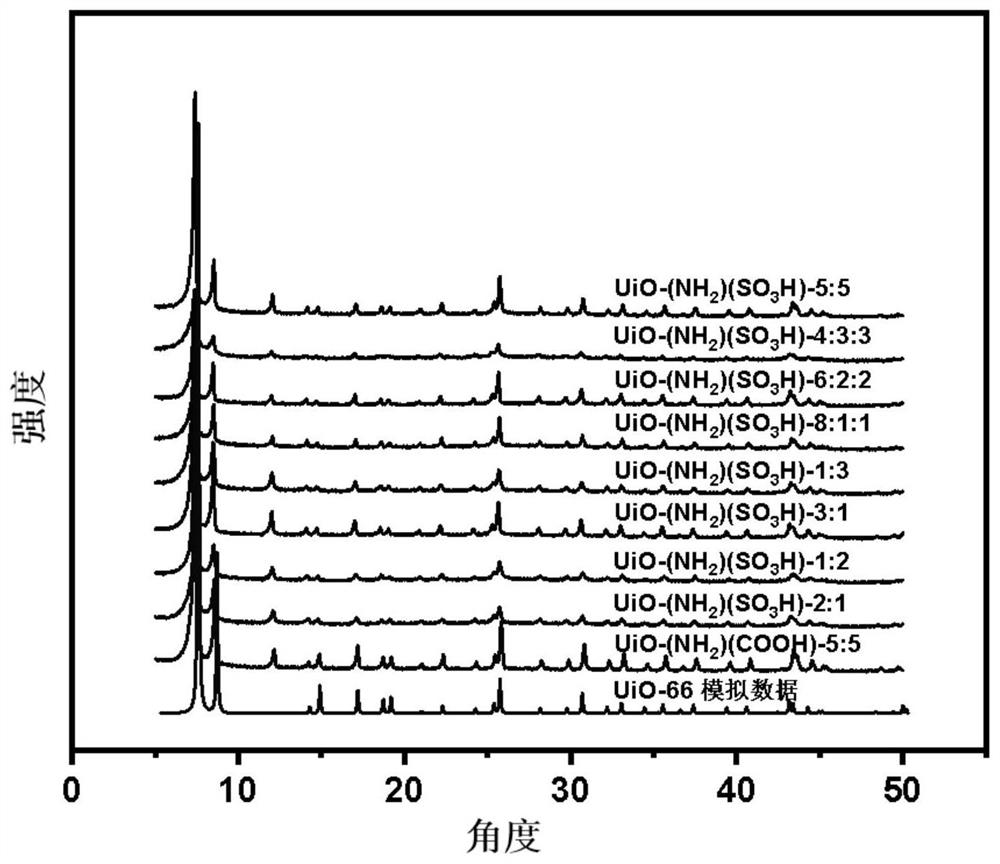

[0040] A MOF material with adjustable proton conductivity. Organic ligands containing acidic groups and basic groups are introduced into the synthesis solution at the same time, and MOF materials modified with acidic groups and basic groups are synthesized in one step by solvent replacement. , by changing the concentration and ratio of acidic groups and basic groups in MOF materials, the proton conductivity of MOF materials can be further regulated.

[0041] The proton conduction mechanism of the MOF material is as follows: on the one hand, both acidic and basic groups have good hydrophilicity, and form hydrogen bonds with water molecules in the MOF material skeleton to promote dense and continuous hydrogen bonds in the MOF material. Network element generation. On the other hand, acidic groups have strong acidity, and as proton donors, protons are easily dissociated from acidic groups and become the main source of protons transported in pores; dissociated protons jump along th...

Embodiment 2

[0052] A preparation method of MOF material with adjustable proton conductivity,

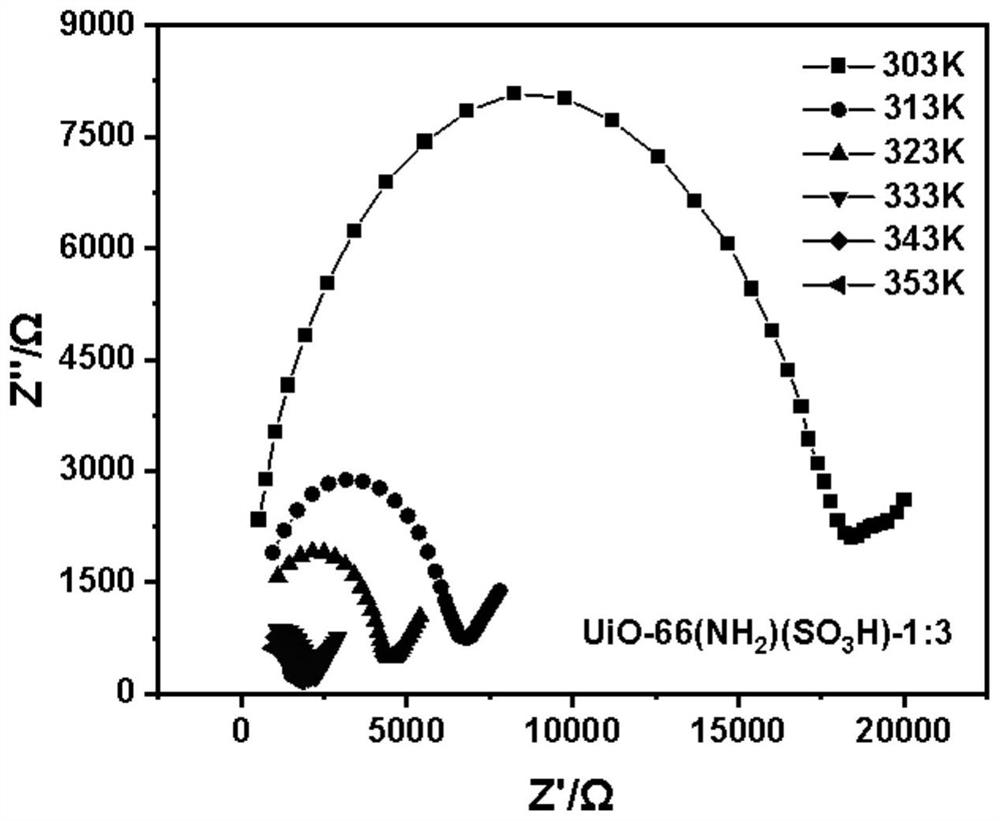

[0053] UiO-66-(NH 2 )(SO 3 The concrete steps of the preparation method of F)-1:3 are:

[0054] Accurately weigh 0.003mol of zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O), 0.00225mol of 2,5-dicarboxybenzenesulfonic acid monosodium salt (BDC-SO 3 Na) and 0.00075mol of 2-aminoterephthalic acid are placed in a beaker, add 30ml N,N-dimethylacetamide (DMA) and stir evenly, add 11.7ml formic acid after the solid is fully dissolved, and transfer the liquid to 100ml polytetrafluoroethylene high-pressure reaction kettle, reacted in an oven at 150°C for 24 hours, and centrifuged the crude product after the mixture was cooled to room temperature. The crude product was washed three times with N,N-dimethylacetamide and acetone respectively, and the product was Place it in a vacuum oven at 80°C for 12 hours to obtain the product UiO-66-(NH 2 )(SO 3 H)-1:3 (1:3 means that the molar ratio of 2-amin...

Embodiment 3

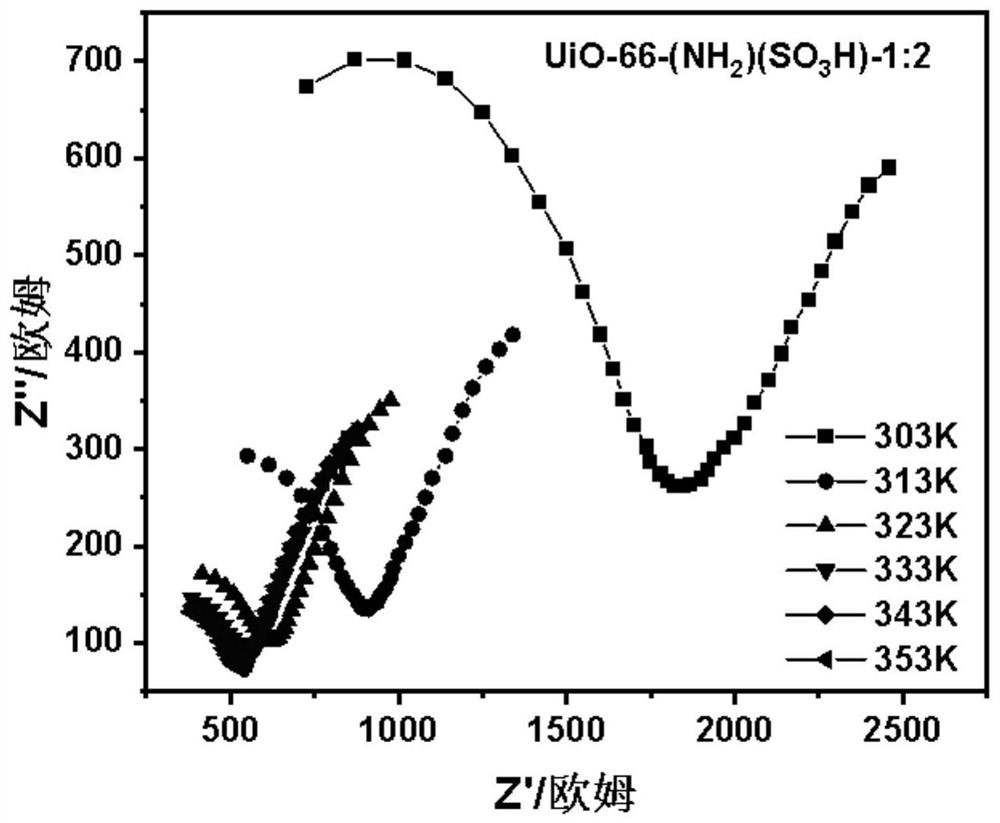

[0057] A preparation method of MOF material with adjustable proton conductivity,

[0058] UiO-66-(NH 2 )(SO 3 The concrete steps of the preparation method of F)-1:2 are:

[0059] Accurately weigh 0.003mol of zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O), 0.002mol of 2,5-dicarboxybenzenesulfonic acid monosodium salt (BDC-SO3Na) and 0.001mol of 2-aminoterephthalic acid are placed in a beaker, add 30mlN,N-dimethylacetamide ( DMA) and stir evenly, add 11.7ml of formic acid after the solid is fully dissolved, transfer the liquid to a 100ml polytetrafluoroethylene autoclave after mixing evenly, react in a 150°C oven for 24h, and centrifuge the crude product after the mixture is cooled to room temperature , the crude product was washed three times with N,N-dimethylacetamide and acetone, and the product was dried in a vacuum oven at 80°C for 12 hours to obtain the product UiO-66-(NH 2 )(SO 3 H)-1:2 (1:2 means that the molar ratio of 2-aminoterephthalic acid and 2,5-dicarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com