Optical fiber sensor based on hybrid cascade structure and preparation method

An optical fiber sensor, hybrid cascade technology, applied in instruments, scientific instruments, optical devices, etc., can solve problems such as increasing system complexity and cost, affecting sensor measurement accuracy, and measuring a single physical quantity, achieving good performance and simple structure. Compact, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

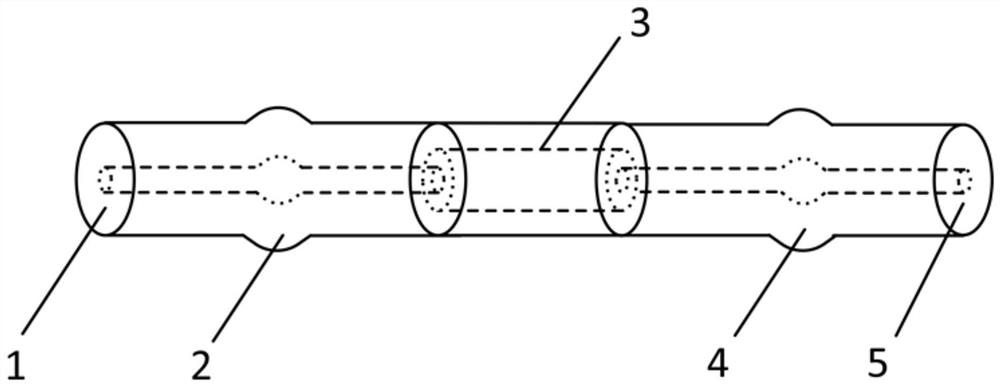

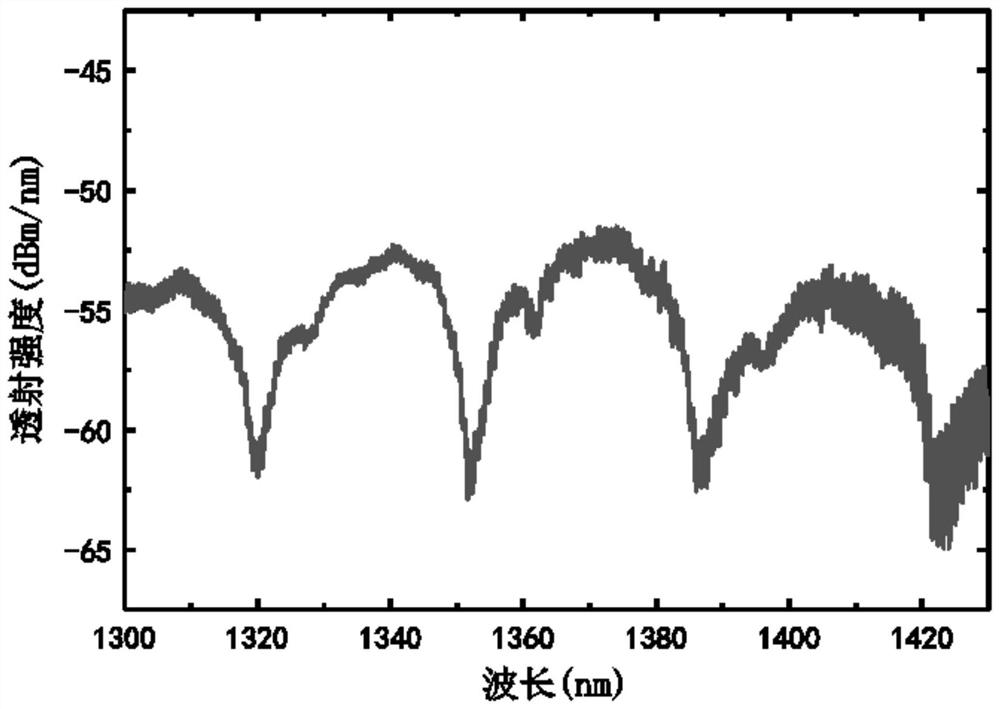

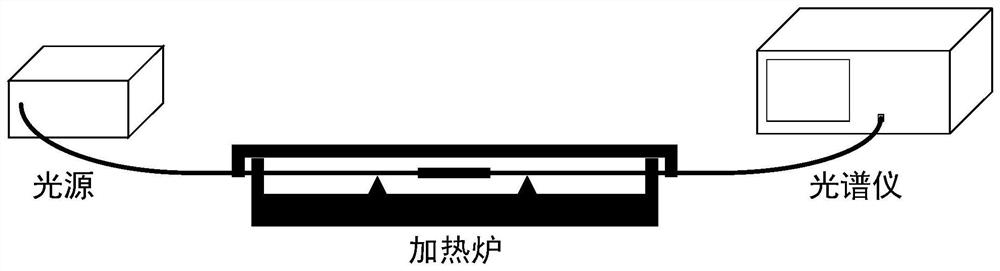

[0027] Embodiment one: if figure 1 As shown, based on the hybrid structure optical fiber sensor based on the hollow-core fiber cascaded with the fused-cone single-mode fiber, the fused-cone single-mode fiber-2 and the fused-cone single-mode fiber formed by the single-mode fiber are cascaded at both ends of the capillary glass tube 3. 2. 4. An input optical fiber 1 and an output optical fiber 5 are arranged at both ends of the hybrid structure 2, 3, and 4; the input end of the optical fiber sensor is connected to the light source through the optical fiber 1, the output end is connected to the spectrometer through the output optical fiber 5, and the input optical fiber 1 and The output optical fiber 5 is a single-mode optical fiber; the inner diameter of the capillary glass tube 3 is 75 μm, the outer diameter is 125 μm, and the length is 3-10 mm; when the temperature and curvature of the detection area change, the position of the characteristic transmission peak in the cascade sp...

Embodiment 2

[0029] Embodiment 2: The two ends of the capillary glass tube are cascaded with a convex tapered optical fiber fused from a single-mode optical fiber, and an input optical fiber and an output optical fiber are arranged at both ends of the hybrid structure. The inner diameter of the capillary glass tube is 75 μm, the outer diameter is 125 μm, and the selected length is 5 mm. The single-mode fiber used is a standard single-mode fiber. When the temperature and curvature of the detection area change, the characteristic transmission peak in the cascade spectrum changes. The position and intensity will change. After analyzing the position and intensity of the fine spectral fringes collected by the spectrometer and fast Fourier filtering, the changes in the wavelength and intensity of the anti-resonance transmission peak of the capillary glass tube are detected and specific Signal processing can realize the detection of temperature and curvature changes.

Embodiment 3

[0030] Embodiment 3: The preparation method of the hybrid structure optical fiber sensor based on hollow-core optical fiber cascaded fused cone single-mode optical fiber, comprises the following steps:

[0031] S1. Single-mode optical fiber pretreatment: select two single-mode optical fibers with an inner diameter of 8 μm and an outer diameter of 125 μm, use fiber strippers or blades to remove the coating protective layer of the optical fiber, and wipe the surface of the optical fiber with alcohol to remove its residue ; Use a fiber cleaver to cut one end of the fiber flat.

[0032] S2. Production of convex tapered optical fiber: Use an optical fiber fusion splicer to fuse two single-mode optical fibers processed by S1 together; set the fusion splicing parameters of the optical fiber fusion splicer as follows: use fiber core alignment, overlap 150 μm, and discharge intensity Standard intensity, the discharge time is 2000ms, the second discharge intensity is the standard intens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com