Method for growing GaN film on graphene

A technology of graphene and graphene layer, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems such as the difficulty of GaN film formation, achieve low stress, promote lateral merger, and high crystal quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

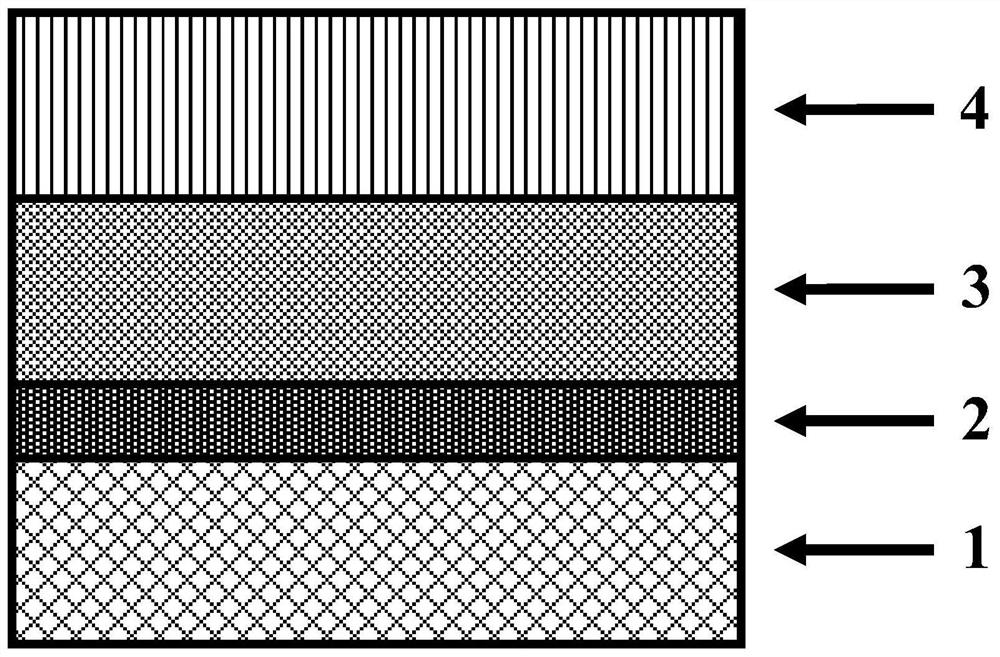

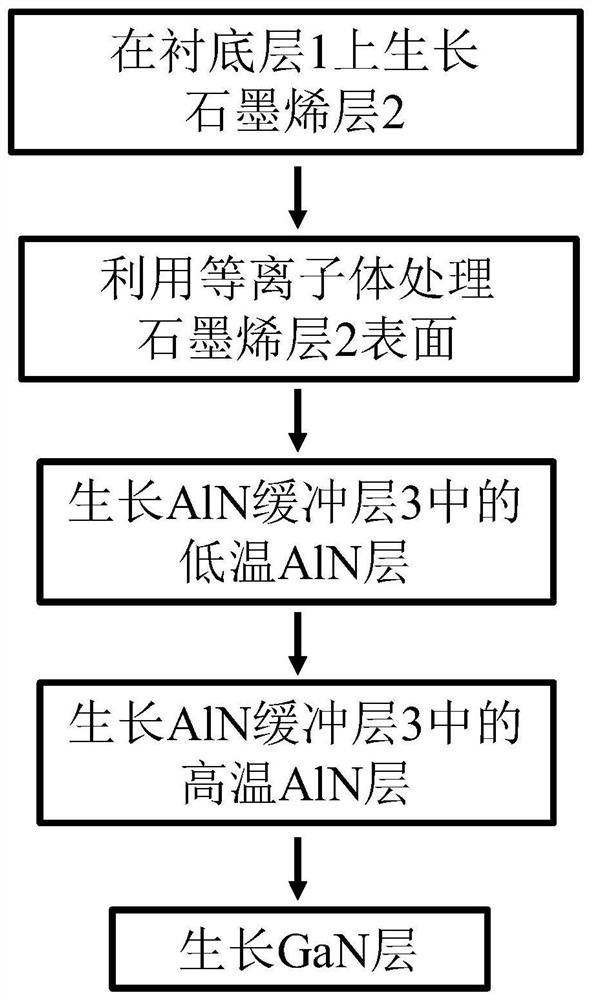

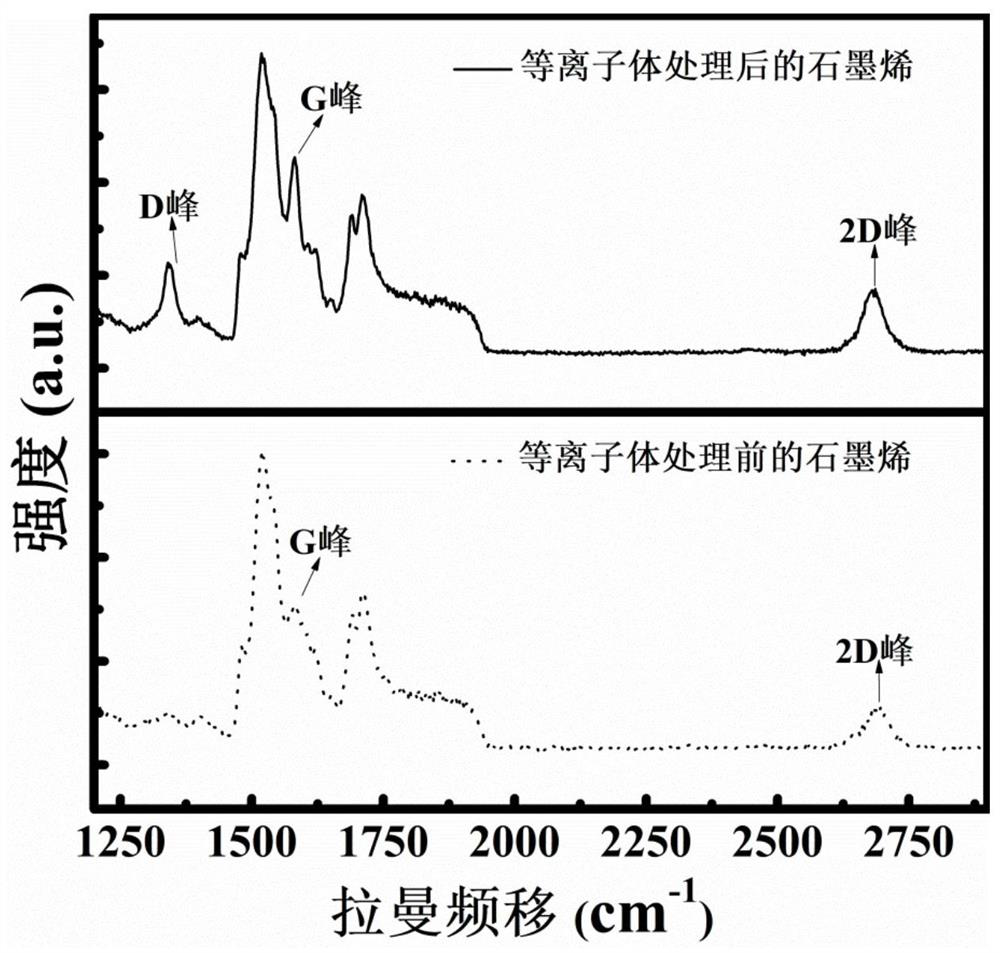

[0020] 1. A three-layer graphene layer 2 is grown on a SiC substrate 1 by a thermal decomposition SiC method. The SiC substrate 1 was annealed at 900° C. for 1 hour in an argon atmosphere, and the annealing pressure was 400 mbar. Then, continue heating to 1600° C. in an argon atmosphere at 800 mbar for 3 hours to realize the growth of three graphene layers 2 on the surface of the SiC substrate 1 . Then, the surface of the graphene layer is treated with plasma surface pretreatment technology, the working gas of plasma treatment is nitrogen, the temperature is room temperature, the power is 50W, and the treatment time is 30s. Afterwards, the MOCVD method is used to sequentially prepare an AlN buffer layer 3 (thickness 200nm) on the graphene layer 2 prepared on the SiC substrate 1, wherein the low-temperature AlN layer with a thickness of 40nm is first epitaxy, and then the remaining 160nm-thick high-temperature AlN layer is epitaxially increased in temperature. layer) and GaN l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com