Power generation glass for photovoltaic building integration and preparation method of power generation glass

A photovoltaic building and glass technology, applied in photovoltaic power generation, supporting structures of photovoltaic modules, photovoltaic modules, etc., can solve problems such as poor sound insulation effect, increased energy consumption of buildings, and poor heat insulation ability, so as to increase light transmission pass, increase the absorption utilization rate, and avoid the effect of poor visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

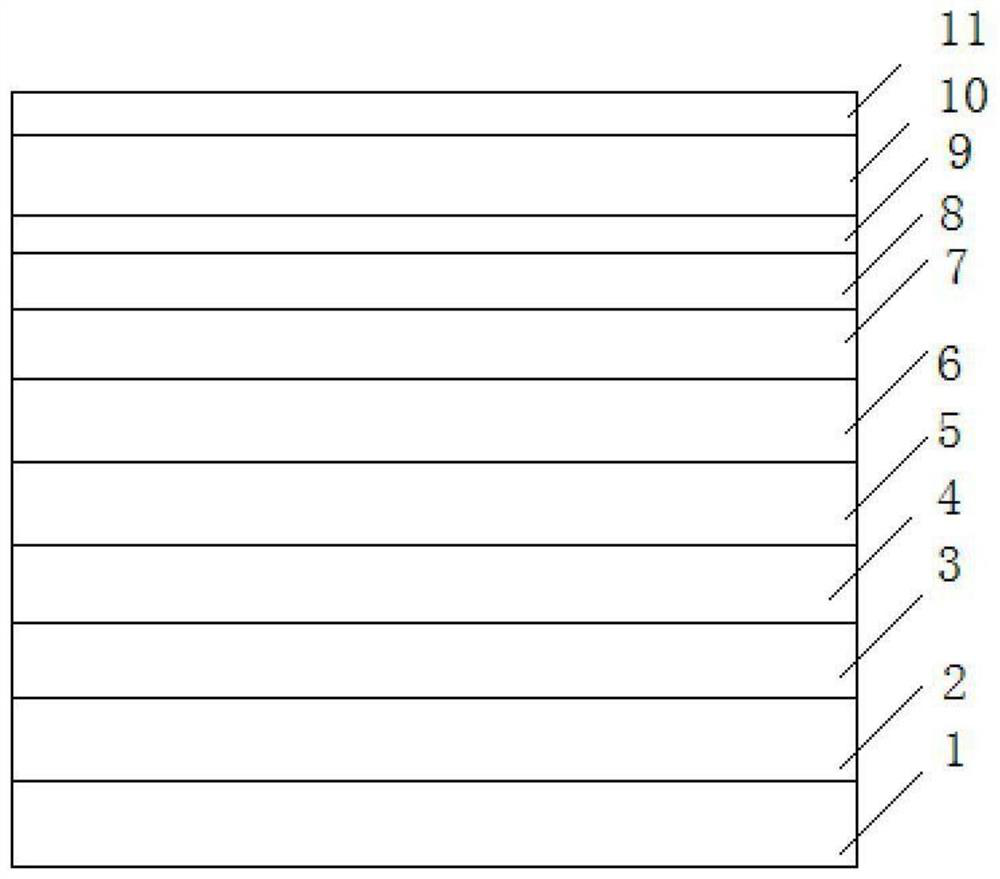

[0039] Such as figure 1 As shown, a kind of power generation glass for building integrated photovoltaics includes anti-reflection film coating 1, first glass substrate layer 2, first adhesive film 3, second glass substrate layer 4, transparent conductive film from bottom to top 5. Window layer 6, absorption layer 7, back contact layer 8, back electrode layer 9, second adhesive film 10 and back glass layer 11; the material of the window layer 6 is cadmium sulfide, and the material of the absorption layer 7 is tellurium Cadmium;

[0040] The power generation glass is cadmium telluride power generation glass, which is a cadmium telluride solar cell module;

[0041]The anti-reflection film coating 1 is an AR anti-reflection film coating, the material of the first glass substrate layer 2 and the second glass substrate layer 4 is ultra-clear float glass, and the material of the back glass layer 2 is Tempered glass; the central region of the second adhesive film 10 is a PVB layer, ...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is that the material of the absorbing layer is selenium-doped cadmium telluride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com