Implant for preventing bone cement leakage, preparation method and application, complete set of products for preventing bone cement leakage and using method

An implant and bone cement technology, applied in the field of medical devices, can solve the problems of poor dispersion of bone cement, gaps between bone cement and bone, and outflow of bone cement, and achieve good biocompatibility and biosafety. Flow, small pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] According to a second aspect of the present invention, a method for preparing an implant for preventing bone cement leakage is provided, comprising the following steps:

[0066] The unmodified or modified PMMA polymer solution is electrospun to form fibers, which are received by a receiving device and dried to obtain a film-shaped implant, then immersed in a developer solution and dried to obtain a film-shaped implant with developability. implants; or,

[0067] The unmodified or modified PMMA polymer solution is mixed with a developer for electrospinning to form fibers, which are received by a receiving device and dried to obtain a film-like implant with developability.

[0068] "Unmodified or modified PMMA polymer solution" refers to a solution of unmodified PMMA polymer, or, a modified PMMA polymer solution.

[0069] "Unmodified or modified PMMA polymer solution and developer" means "unmodified PMMA polymer solution and developer, or, modified PMMA polymer solution a...

Embodiment 1

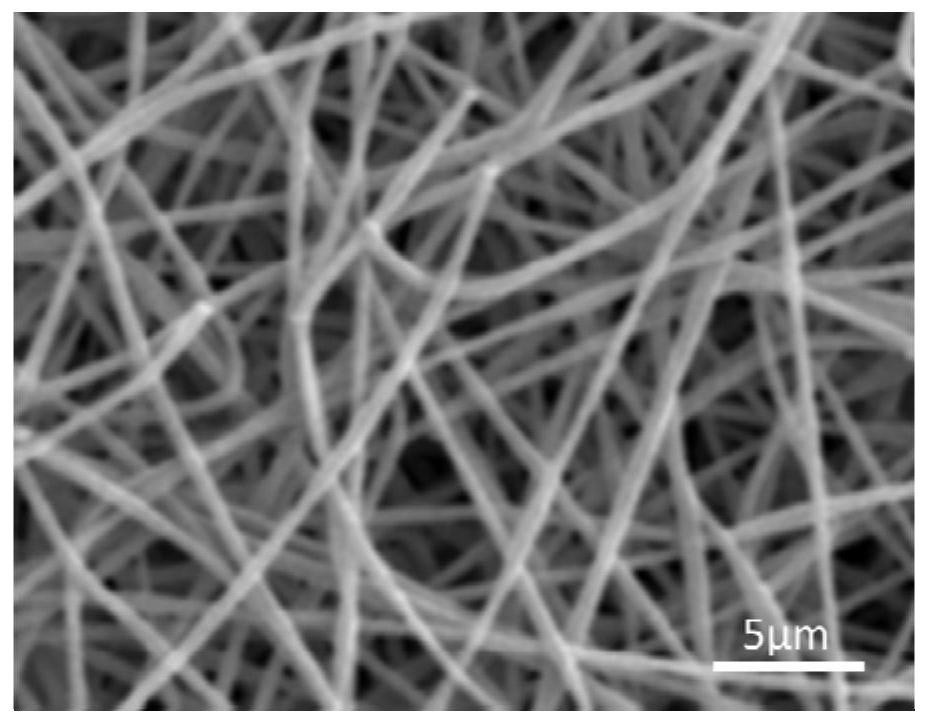

[0098] Take by weighing the PMMA powder of 5g, slowly add the mixed solvent (DMF:toluene=1:2) of the DMF of 57.5g and toluene therein, preparation concentration is the solution of 8wt%, it is carried out heating magnetic stirring 24h, until polymer is completely When the dissolved and obtained solution is very uniform, transfer it to a 10ml syringe, select a 24G spinning needle to connect the syringe, place it on the electrospinning device and fix it, and turn on the power supply connection voltage, adjust the spinning voltage to 10kV, and spin The distance is 20cm, the spinning speed is 0.8ml / h, and the spinning time is 2.5h. The nanofibers obtained under the conditions are relatively uniform in diameter and good in shape, as shown in figure 1 As shown, the fiber diameter is about 590-680nm, the nanofiber membrane thickness is about 108μm, the pore diameter is about 1.48μm, and the specific surface area is 33m 2 / g. Subsequently, the obtained nanofiber patch was immersed in ...

Embodiment 2

[0100] Take by weighing the PMMA powder of 5g, in the mixed solvent (DMF:toluene=1:2) of the DMF and toluene of slowly adding 36.7g wherein, preparation concentration is the solution of 12wt%, it is carried out heating magnetic stirring 24h, treat polymer When the solution is completely dissolved and the obtained solution is very uniform, transfer it to a 10ml syringe, select a 24G spinning needle to connect the syringe, place it on the electrospinning device and fix it, and turn on the power supply connection voltage, adjust the spinning voltage to 10kV, and spin The filament distance is 20cm, the spinning speed is 0.8ml / h, and the spinning time is 2.5h. Under these conditions, the fiber diameter obtained is relatively uniform and the shape is good. The fiber diameter is 750-900nm, and the thickness of the nanofiber film is 127μm About, the pore diameter is about 2.52μm, the specific surface area is 28m 2 / g, have the same good performance and use effect as Example 1 after so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com