Preparation method of forward osmosis membrane material

A forward osmosis membrane and base membrane technology, applied in the field of membrane separation, to achieve the effects of long running time, high water flux recovery rate, high mechanical strength and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

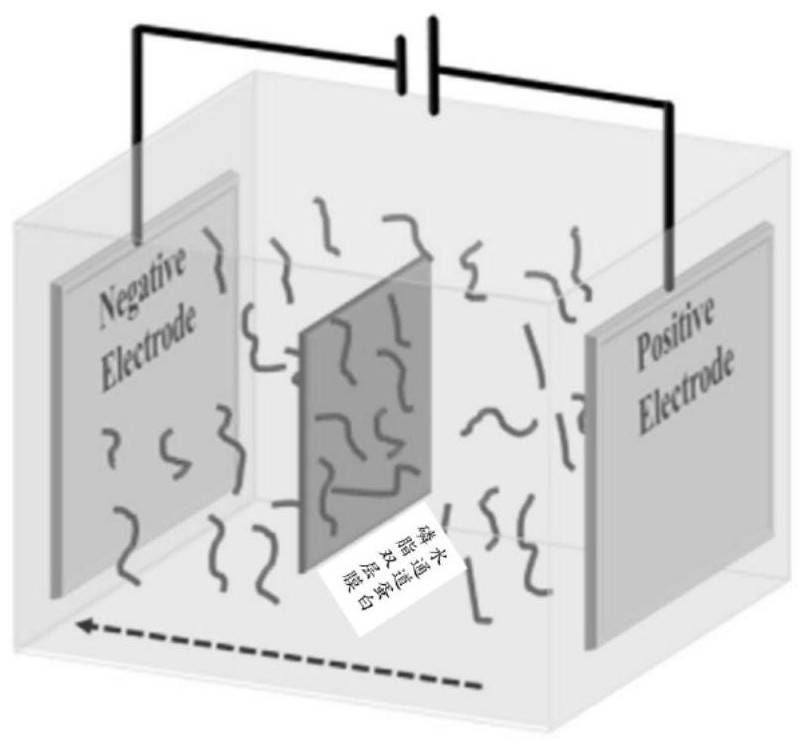

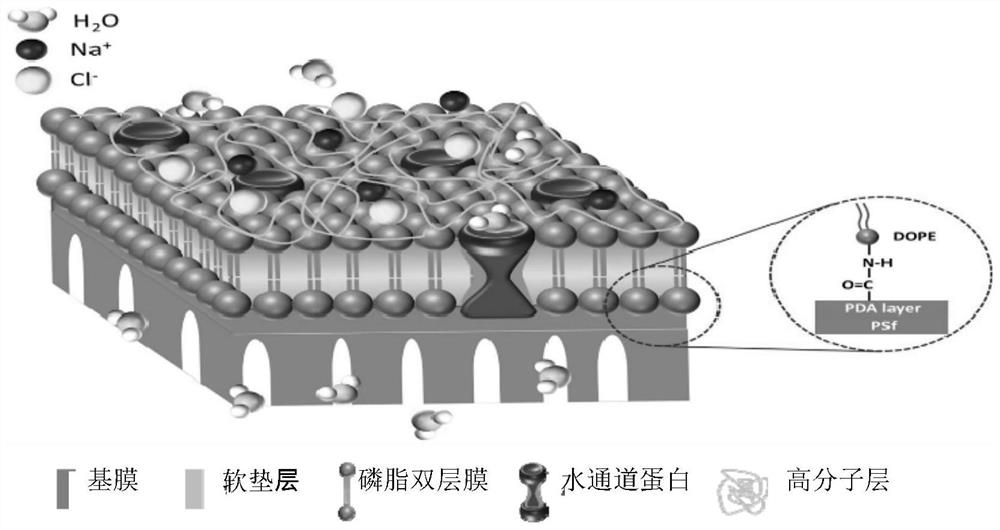

Method used

Image

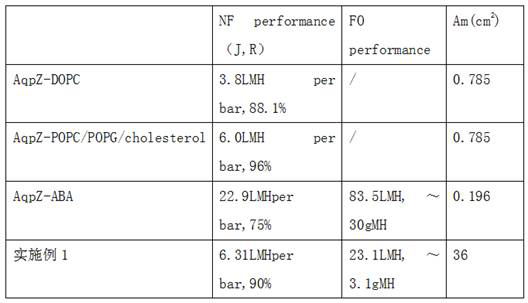

Examples

Embodiment 1

[0037] (1) Preparation of basement membrane:

[0038] a. Casting solution: Dissolve 18 g of polylactic acid (PLA) solid in 81 g of N,N-dimethylacetamide (DMAC) solution, add 6 g of polyethylene glycol-400 (PEG-400 ), the prepared casting solution was placed at 70 °C for 24 h at constant temperature and stirred at 40 °C for 24 h to ensure that the casting solution was evenly dispersed and the air bubbles were removed. The defoamed cast film The solution is placed at room temperature for later use;

[0039] b. Non-woven fabric pretreatment: Soak the non-woven fabric in NaOH with a mass fraction of 25% for 15 minutes, transfer to an ethanol solution with a mass fraction of 50% and continue soaking for 15 minutes, then rinse with deionized water, and dry for later use .

[0040] c Scraping film: pour the casting solution at room temperature on the pretreated non-woven fabric, scrape the casting solution with a scraper to form a 110 μm thick flat film, pre-evaporate for 30 s, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com