Tri(dimethylamine)cyclopentadiene hafnium production method

A technology for cyclopentadiene, a production method, applied in the directions of bulk chemical production, chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, etc., capable of solving tris(dimethylamine)cyclopentadiene hafnium The problem of low purity, etc., can avoid the formation of by-products, improve the purity, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

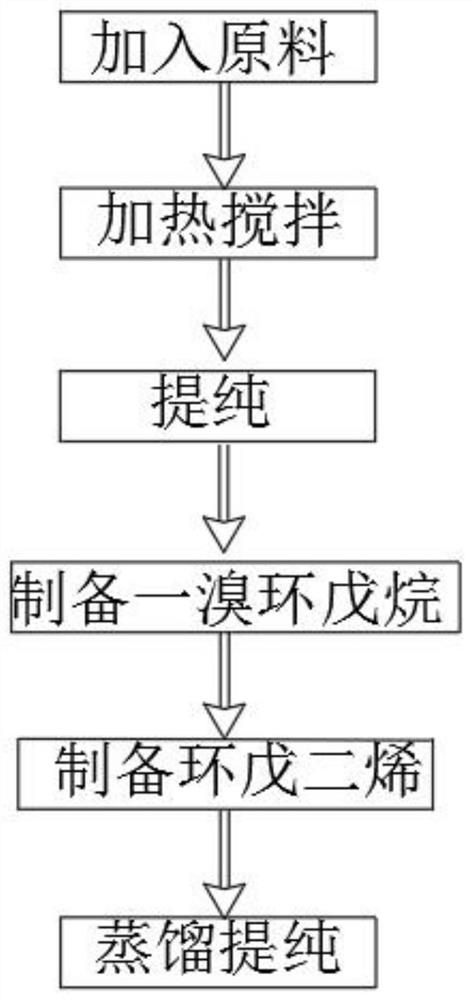

[0031] refer to figure 1 , three (dimethylamine) cyclopentadiene hafnium production method, comprises the following steps:

[0032] S1: Add raw materials, under the protection of an inert atmosphere, add 20-60 parts of hafnium tetrachloride to the flask; 1000-1800 parts of ionic liquid buffer solvent to facilitate the reaction of objects, and 100-300 parts of lithium salt of dimethylammonia;

[0033] S2: heating and stirring, heating during reaction, and then intermittent stirring;

[0034] S3: Purification, adding activated carbon particles to the reacted solution, fully stirring with a glass rod after adding, then filtering after standing for 10-30 minutes, collecting the filtrate to obtain high-precision tetrakis (dimethylamino) hafnium;

[0035] S4: prepare bromocyclopentane, select cyclopentane, make it react with bromine under light to obtain bromocyclopentane;

[0036] S5: To prepare cyclopentadiene, take monobromocyclopentane and heat it in the alcohol solution of so...

Embodiment 2

[0041] refer to figure 1 , three (dimethylamine) cyclopentadiene hafnium production method, comprises the following steps:

[0042] S1: Add raw materials, under the protection of an inert atmosphere, add 20-60 parts of hafnium tetrachloride to the flask; 1000-1800 parts of ionic liquid buffer solvent to facilitate the reaction of objects, and 100-300 parts of lithium salt of dimethylammonia;

[0043] S2: heating and stirring, heating during reaction, and then intermittent stirring;

[0044] S3: Purification, adding activated carbon particles to the reacted solution, fully stirring with a glass rod after adding, then filtering after standing for 10-30 minutes, collecting the filtrate to obtain high-precision tetrakis (dimethylamino) hafnium;

[0045] S4: prepare bromocyclopentane, select cyclopentane, make it react with bromine under light to obtain bromocyclopentane;

[0046] S5: To prepare cyclopentadiene, take monobromocyclopentane and heat it in the alcohol solution of so...

Embodiment 3

[0051] refer to figure 1 , three (dimethylamine) cyclopentadiene hafnium production method, comprises the following steps:

[0052] S1: Add raw materials, under the protection of an inert atmosphere, add 20-60 parts of hafnium tetrachloride to the flask; 1000-1800 parts of ionic liquid buffer solvent to facilitate the reaction of objects, and 100-300 parts of lithium salt of dimethylammonia;

[0053] S2: heating and stirring, heating during reaction, and then intermittent stirring;

[0054] S3: Purify, distill the reacted solution under reduced pressure, and collect fractions at 76-79°C / 5-9mmHg;

[0055] S4: prepare bromocyclopentane, select cyclopentane, make it react with bromine under light to obtain bromocyclopentane;

[0056] S5: To prepare cyclopentadiene, take monobromocyclopentane and heat it in the alcohol solution of sodium hydroxide to obtain cyclopentene, then react with bromine carbon tetrachloride solution to obtain o-dibromocyclopentane, and finally reheat El...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com