A Method for All-weather Generation of Photothermal Vapor by Near-total Absorption of Sunlight by Coupled Gain Localized Surface Plasmon Resonance Absorbers

A plasmon resonance and localized surface technology, which is applied in the steam generation method using solar energy, the steam generation method, the components of solar collectors, etc., can solve the problems of difficult improvement of light absorption characteristics and limited coverage of absorption spectrum , to achieve the effects of strong weather resistance, excellent light absorption characteristics, and excellent comprehensive light-to-heat conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

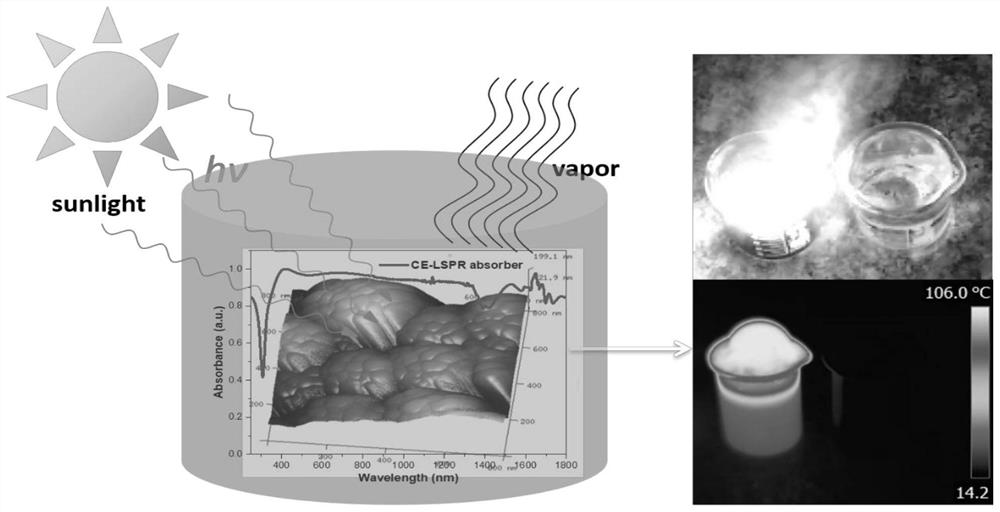

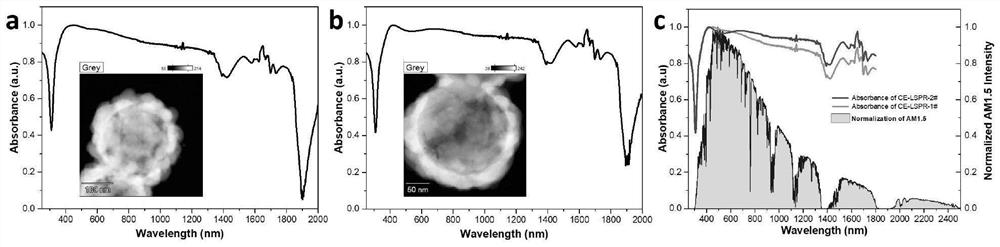

[0039] Example 1: Preparation of CE-LSPR absorber that absorbs nearly all sunlight and outdoor all-weather series of photothermal conversion to generate 3H photothermal steam

[0040] (1) Amorphous SiO 2 Preparation of nanospheres, configuration solutions A and B, A: 3.17ml TEOS+25ml H 2 O; B: 2.52ml (25wt%) NH 3 ·H 2 O+1.8ml H 2O+25ml EtOH; A and B were mixed and stirred vigorously for 30 minutes, reacted at 50°C for 3h, centrifuged at 5000rpm with absolute ethanol for 2-3 times, and the centrifugal sediment was dried at 105°C to obtain amorphous SiO 2 Nanospheres (particle size: 200±10 nm).

[0041] (2) Preparation of highly efficient loading nanocrystals on amorphous nano-cores, 0.72g of amorphous SiO obtained in step (1) 2 Nanospheres dispersed in 30ml deionized water, 30ml 0.15mol / LK 4 [Fe(CN) 6 ]·3H 2 O stirred for 1 h, centrifuged at 5000 rpm and washed 3 times with water. Wash the sediment and then disperse it in 30ml deionized water, disperse it with ultrason...

Embodiment 2

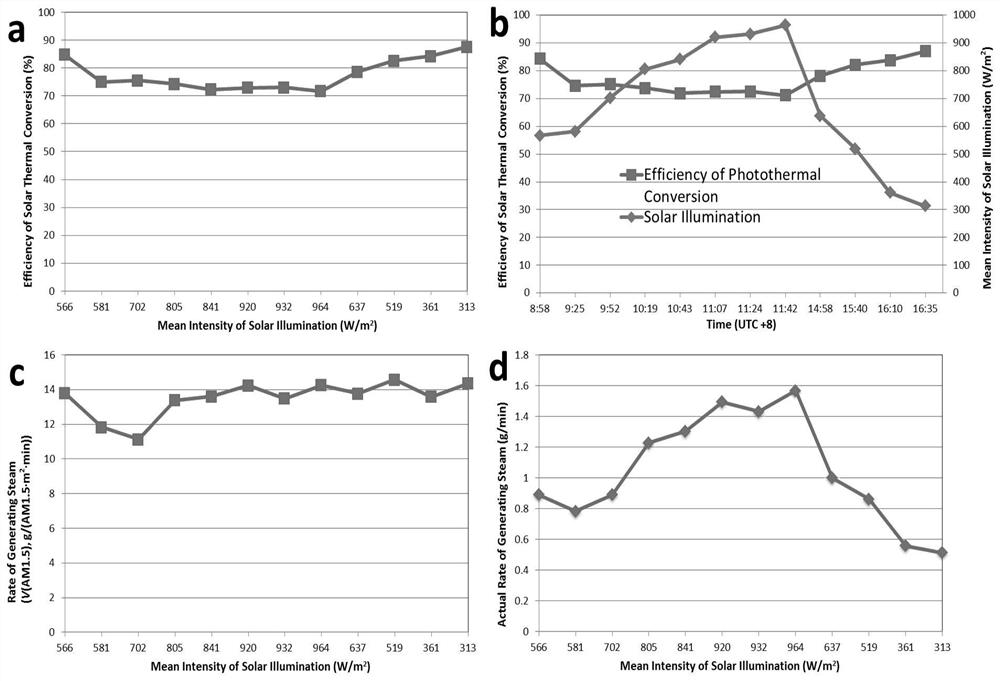

[0049] Referring to Example 1, the difference is that the concentration of the absorber in step (4) is increased to 1.2-1.5 times, and the intensity of sunlight is ~875W / m in turn 2 、~910W / m 2 、~719W / m 2 、~690W / m 2 . After the concentration of the CE-LSPR absorber that absorbs sunlight almost completely increases, the comprehensive photothermal performance of the CE-LSPR absorber is better, and the comprehensive photothermal conversion performance ηce, V(AM1.5 ) and Va were 87.65% ( Figure 4 (a)), 19.30g / (AM1.5 m 2 min)( Figure 4 (c)) and 1.52g / min (light collecting area: 35×35cm, Figure 4 (d,e)). The photothermal steam produced is high temperature superheated steam (see Figure 4 (g)), a large amount of high-temperature steam is released rapidly in the irradiation area (see Figure 4 (f)).

Embodiment 3

[0051] Referring to Example 1, the difference is that in step (1) amorphous SiO 2 Nanospheres (particle size: 220±10nm) use 3.78ml (25wt%) NH 3 ·H 2 O was reacted at room temperature for 3 h to prepare amorphous SiO 2 Nanospheres; add silver ammonia solution in step (2) and react for 2h; step (3) add 128mg silver nitrate and stir evenly, the concentration of silver nitrate is 3.75*10 -3 mol / L, 5ml0.4mol / L hydrazine hydrate solution, heated and matured in a water bath for 12h; in step (4), sunshine 09:41am-16:25pm, average sunlight intensity 883-371W / m 2 , with the passage of sunshine time, the average sunlight intensity of outdoor light-to-heat conversion at different time points in all weathers from weak to strong and then to weak, in order: ~714W / m 2 、~745W / m 2 、~790W / m 2 、~883W / m 2 、~879W / m 2 、~868W / m 2 、~856W / m 2 、~848W / m 2 、~833W / m 2 、~854W / m 2 、~770W / m 2 、~725W / m 2 、~597W / m 2 、~525W / m 2 、~493W / m 2 、~447W / m 2 、~371W / m 2 .

[0052] The temperature of ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com