Cavity filtering antenna with high gain, high selectivity and low loss

A high-selectivity, cavity filtering technology, applied in the field of communication antennas, can solve the problems of low gain, large antenna volume, and poor radiation characteristics, and achieve the effects of low processing cost, high filtering performance, and high gain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

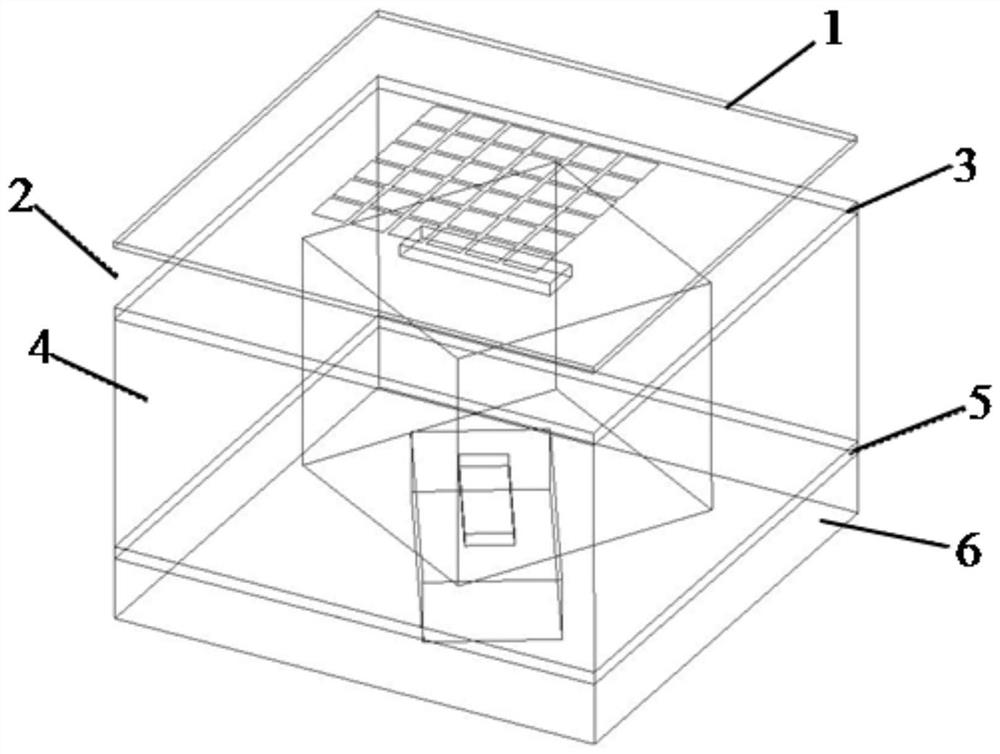

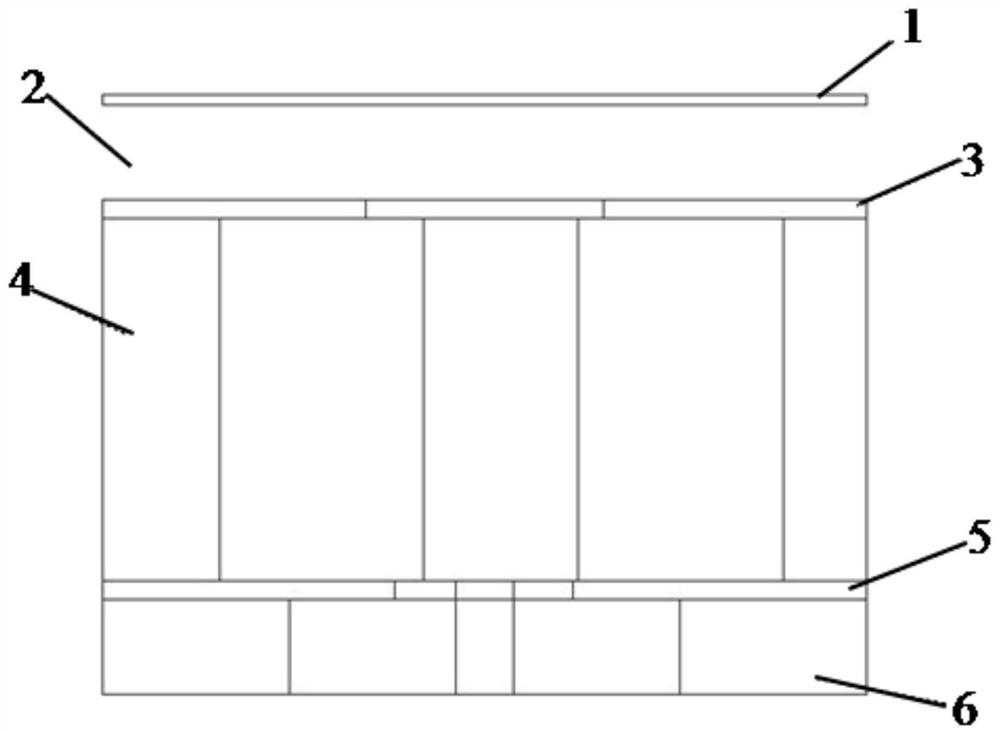

[0025] see Figure 1 to Figure 7 As shown, this embodiment provides a cavity filter antenna with high gain, high selectivity and low loss, including a dielectric plate 1, a first metal block 3, a second metal block 4, and a third metal plate arranged in sequence from top to bottom. Block 5, the fourth metal block 6, the distance between the dielectric plate 1 and the first metal block 3 is kept 5mm, an air layer 2 is formed, the first metal block 3, the second metal block 4, the third metal block Both the block 5 and the fourth metal block 6 are cuboid metal blocks;

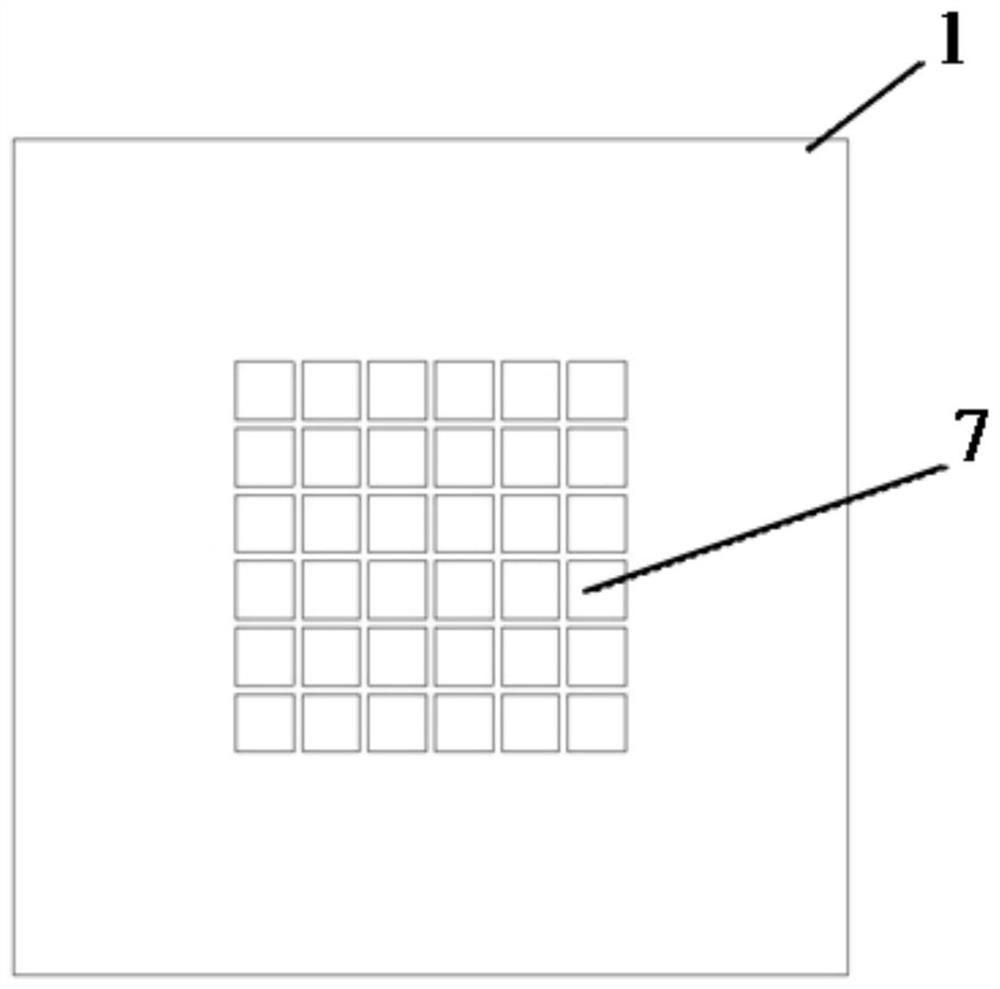

[0026] Wherein, the grid slotted patch 7 is provided on the dielectric board 1, and the grid slotted patch 7 is a 6×6 square patch for improving the gain of the antenna; the first metal block 3 The thickness is 1 mm, and the middle part of the first metal block 3 has a radiation hole 8, which is a rectangular h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com