Preparation method and application of feed additive

A technology of feed additives and materials, applied in applications, animal feed, animal feed, etc., can solve problems such as increased feeding costs, threats to human health, and single functions, so as to reduce the use of antibiotics, improve immunity, and increase egg production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

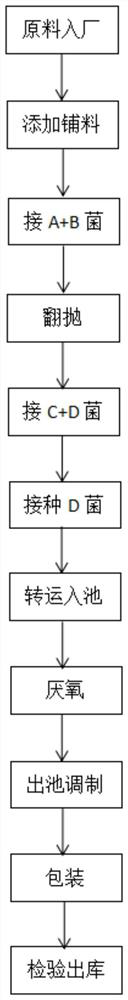

[0050]A preparation method of a feed additive, the production process is as follows figure 1 As shown, it specifically includes the following steps:

[0051] S1. Main material treatment: use cassava residue as the main ingredient, take samples to measure the moisture and starch content of cassava residue, require moisture ≤ 73%, starch (dry product) ≥ 50%, when the moisture exceeds the standard, add cassava flour or cassava granules To adjust to meet the standard; cassava residues enter the factory after reaching the standard, and inoculate within two days after entering the factory;

[0052] S2, aerobic fermentation:

[0053] (1) The main material is put into the tank: the main material is transferred to the aerobic tank, and the height of the material is 50-55cm;

[0054] (2) Adding auxiliary materials: using soybean meal and sodium dihydrogen phosphate as auxiliary materials, the above auxiliary materials are evenly sprinkled on the main material and pre-mixed to obtain t...

Embodiment 2

[0100] A preparation method for a feed additive, specifically comprising the steps of:

[0101] S1. Main material treatment: use cassava residue as the main ingredient, take samples to measure the moisture and starch content of cassava residue, require moisture ≤ 73%, starch (dry product) ≥ 50%, when the moisture exceeds the standard, add cassava flour or cassava granules To adjust to meet the standard; cassava residues enter the factory after reaching the standard, and inoculate within two days after entering the factory;

[0102] S2, aerobic fermentation:

[0103] (1) The main material is put into the tank: the main material is transferred to the aerobic tank, and the height of the material is 50-55cm;

[0104] (2) Adding auxiliary materials: using soybean meal and sodium dihydrogen phosphate as auxiliary materials, the above auxiliary materials are evenly sprinkled on the main material and pre-mixed to obtain the pre-mixed material; The percentages are as follows: soybean...

Embodiment 3

[0114] A preparation method of a feed additive, the production process is as follows figure 1 As shown, it specifically includes the following steps:

[0115] S1, main material processing: take cassava as the main material, take samples to measure the moisture and starch content of cassava residue, require moisture ≤ 73%, starch (dry product) ≥ 50%, when the moisture exceeds the standard, add cassava flour or cassava granules to Adjust to meet the standard; cassava residues enter the factory after reaching the standard, and inoculate within two days after entering the factory;

[0116] S2, aerobic fermentation:

[0117] (1) The main material is put into the tank: the main material is transferred to the aerobic tank, and the height of the material is 50-55cm;

[0118] (2) Adding auxiliary materials: using soybean meal and sodium dihydrogen phosphate as auxiliary materials, the above auxiliary materials are evenly sprinkled on the main material and pre-mixed to obtain the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com