Three-proofing finishing agent and preparation method thereof

A three-proof finishing agent, polyethylene glycol technology, applied in fiber treatment, textiles and papermaking, and liquid-repellent fibers, etc., can solve the problems of difficult cleaning of stains, and achieve good waterproof and oil-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

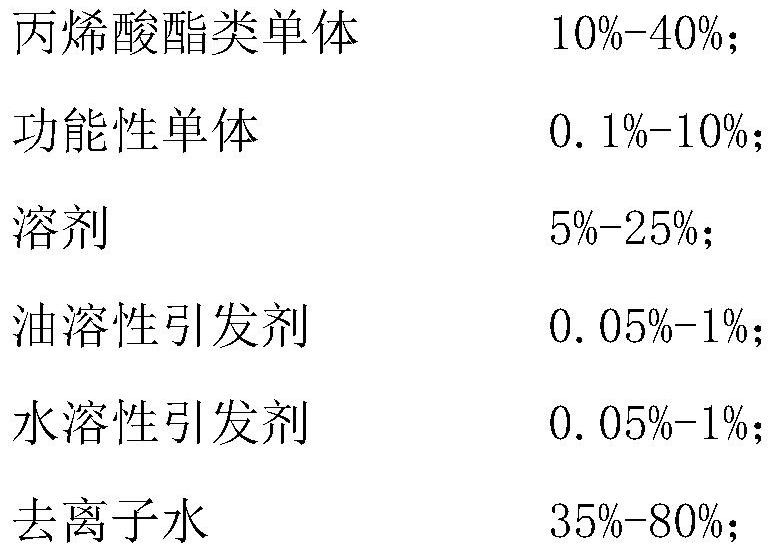

Method used

Image

Examples

Embodiment 1

[0019] A three-proof finishing agent is provided in the embodiment of the present invention, and its components include 21% of acrylic monomers, 2% of functional monomers, 10% of solvents, 0.1% of oil-soluble initiators, and 0.1% of water-soluble initiators. Agent 0.2%, deionized water 66.7%. The three-proof finishing agent is used to improve the waterproof, oil-proof and stain-proof performance of the fabric.

[0020] Wherein, the polyethylene glycol diacrylate material used in the functional monomer is polyethylene glycol 200 diacrylate. The acrylate monomers include about 51.4% of fluorine-containing acrylate monomers and about 41.6% of fluorine-free acrylate monomers. The fluorine-containing acrylate monomer is perfluorohexyl ethyl acrylate. The fluorine-free acrylate monomers include butyl acrylate, glycidyl methacrylate, hydroxyethyl acrylate and methyl methacrylate. The solvent used is N,N-dimethylformamide. The oil-soluble initiator is azobisisobutyronitrile. The ...

Embodiment 2

[0028] A three-proof finishing agent is provided in the embodiment of the present invention, and its components include 21% of acrylic monomers, 2% of functional monomers, 10% of solvents, 0.1% of oil-soluble initiators, and 0.1% of water-soluble initiators. Agent 0.2%, deionized water 66.7%. The three-proof finishing agent is used to improve the waterproof, oil-proof and stain-proof performance of the fabric.

[0029] Wherein, the polyethylene glycol diacrylate material used in the functional monomer is polyethylene glycol 400 diacrylate. The acrylate monomers include about 51.4% of fluorine-containing acrylate monomers and about 41.6% of fluorine-free acrylate monomers. The fluorine-containing acrylate monomer is perfluorohexyl ethyl acrylate. The fluorine-free acrylate monomer includes butyl acrylate, glycidyl methacrylate, hydroxyethyl acrylate, and methyl methacrylate. The solvent used is N,N-dimethylformamide. The oil-soluble initiator is azobisisobutyronitrile. The...

Embodiment 3

[0037]A three-proof finishing agent is provided in the embodiment of the present invention, and its components include 21% of acrylic monomers, 2% of functional monomers, 10% of solvents, 0.1% of oil-soluble initiators, and 0.1% of water-soluble initiators. Agent 0.2%, deionized water 66.7%. The three-proof finishing agent is used to improve the waterproof, oil-proof and stain-proof performance of the fabric.

[0038] Wherein, the polyethylene glycol diacrylate material used in the functional monomer is polyethylene glycol 600 diacrylate. The acrylate monomers include about 51.4% of fluorine-containing acrylate monomers and about 41.6% of fluorine-free acrylate monomers. The fluorine-containing acrylate monomer is perfluorohexyl ethyl acrylate. The fluorine-free acrylate monomer includes butyl acrylate, glycidyl methacrylate, hydroxyethyl acrylate, and methyl methacrylate. The solvent used is N,N-dimethylformamide. The oil-soluble initiator is azobisisobutyronitrile. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com