Water-based antibacterial coating

An antibacterial coating, water-based technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of poor dispersion, toxic and side effects, and short service life of organic antibacterial agents, to achieve inhibition of survival, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

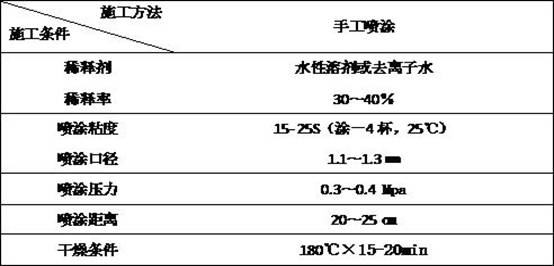

Image

Examples

Embodiment 1

[0012] A method for preparing a water-based antibacterial coating containing polyolefin carbazine siloxane compound. At 20°C, 10 parts of water, 5 parts of ethanol and 1 part of diethylene glycol butyl ether (solvent) are mixed and dropped into the water, then add 1 part of polyolefin-based carbazine and 1 part of siloxane compound to the mixed water, and then drop 0.1 part of diethylene glycol monomethyl ether, 0.3 part of polyacrylate, organic silicon oxide into the mixed water 0.1 part of alkane defoamer, 0.1 part of hydroxyethyl cellulose, 0.1 part of polyurethane rheology modifier, 0.2 part of silicone oil, 0.2 part of polyether polyester modified organosiloxane, and 0.1 part of acrylate. 1.2 parts of water-based additives, and then add 40 parts of water-based fluorocarbon resin to the mixed water and stir for 1 hour to obtain a water-based antibacterial coating.

Embodiment 2

[0014] A method for preparing a water-based antibacterial coating containing polyolefin carbazine siloxane compound. At 40°C, 15 parts of water, 7 parts of ethanol and 3 parts of diethylene glycol butyl ether (solvent) are mixed and dropped into the water, then add 2 parts of polyolefin-based carbazine and 2 parts of siloxane compound to the mixed water, and then add 0.2 parts of diethylene glycol monomethyl ether, 0.3 parts of polyacrylate, organosiloxane 0.1 part of alkane defoamer, 0.1 part of hydroxyethyl cellulose, 0.2 part of polyurethane rheology modifier, 0.2 part of silicone oil, 0.2 part of polyether polyester modified organosiloxane, and 0.1 part of acrylate. 1.4 parts of water-based additives, and then add 50 parts of water-based fluorocarbon resin to the mixed water and stir for 1 hour to obtain a water-based antibacterial coating.

Embodiment 3

[0016] A method for preparing a water-based antibacterial coating containing polyolefin carbazine siloxane compound. At 60°C, 20 parts of water, 10 parts of ethanol and 5 parts of diethylene glycol butyl ether (solvent) are mixed and dropped into the water, then add 4 parts of polyolefin-based carbazine and 4 parts of siloxane compound to the mixed water, and then add 0.2 parts of diethylene glycol monomethyl ether, 0.3 parts of polyacrylate, organosiloxane 0.2 parts of alkane defoamer, 0.2 parts of hydroxyethyl cellulose, 0.2 parts of polyurethane rheology modifier, 0.2 parts of silicone oil, 0.2 parts of polyether polyester modified organosiloxane, and 0.1 part of acrylate ester. 1.6 parts of water-based additives, and then add 60 parts of water-based fluorocarbon resin to the mixed water and stir for 1.5 hours to obtain a water-based antibacterial coating.

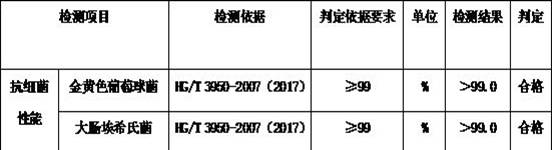

[0017] Table 1: Performance Test Data Sheet

[0018]

[0019] The water-based antibacterial coating of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com