Polyethylene and chlorinated polyethylene thereof

A polyethylene and chemical formula technology, applied in the field of polyethylene and its chlorinated polyethylene, can solve the problems of low chlorine distribution uniformity, insufficient impact strength, etc., and achieve short relaxation time, excellent chlorination productivity, and glass transition temperature excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

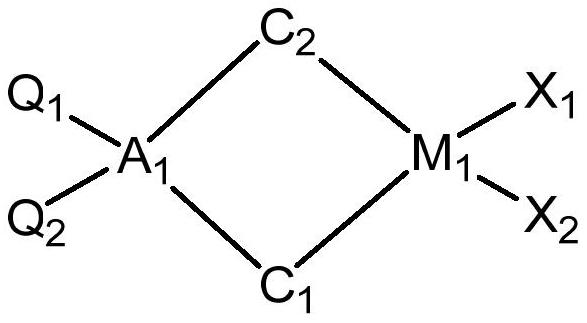

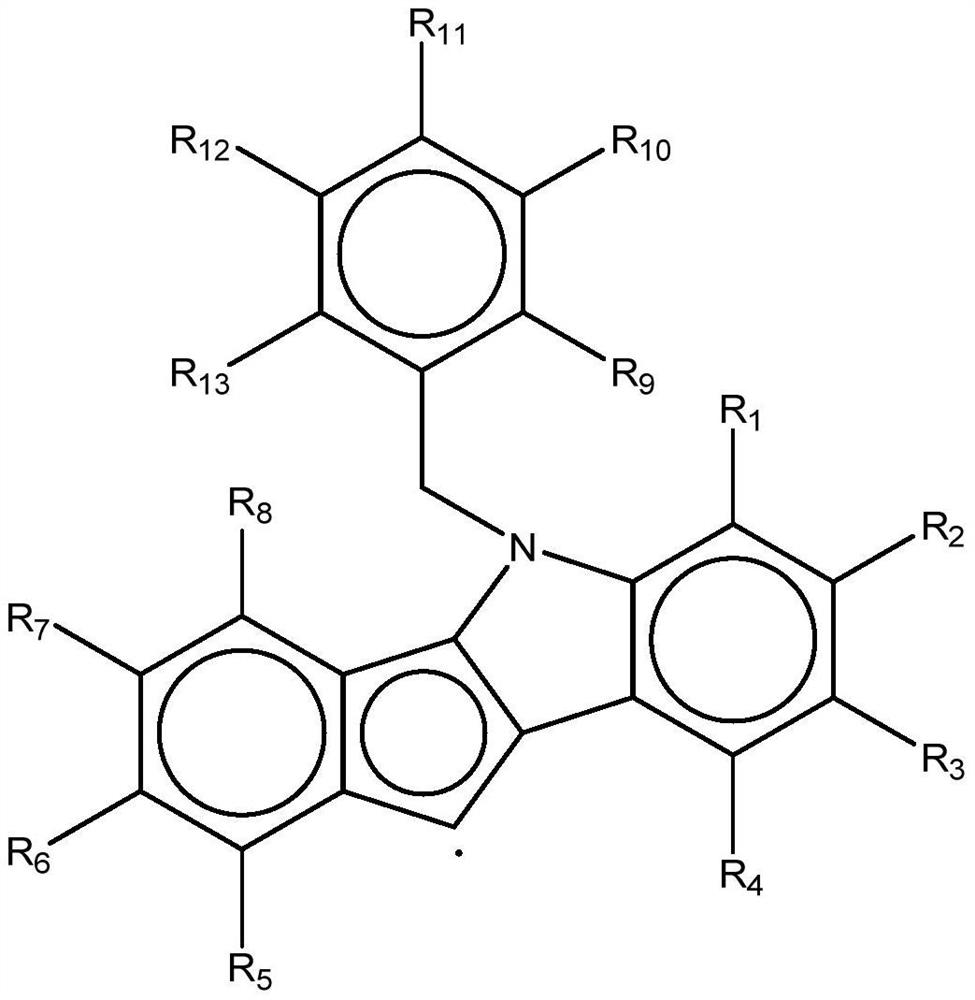

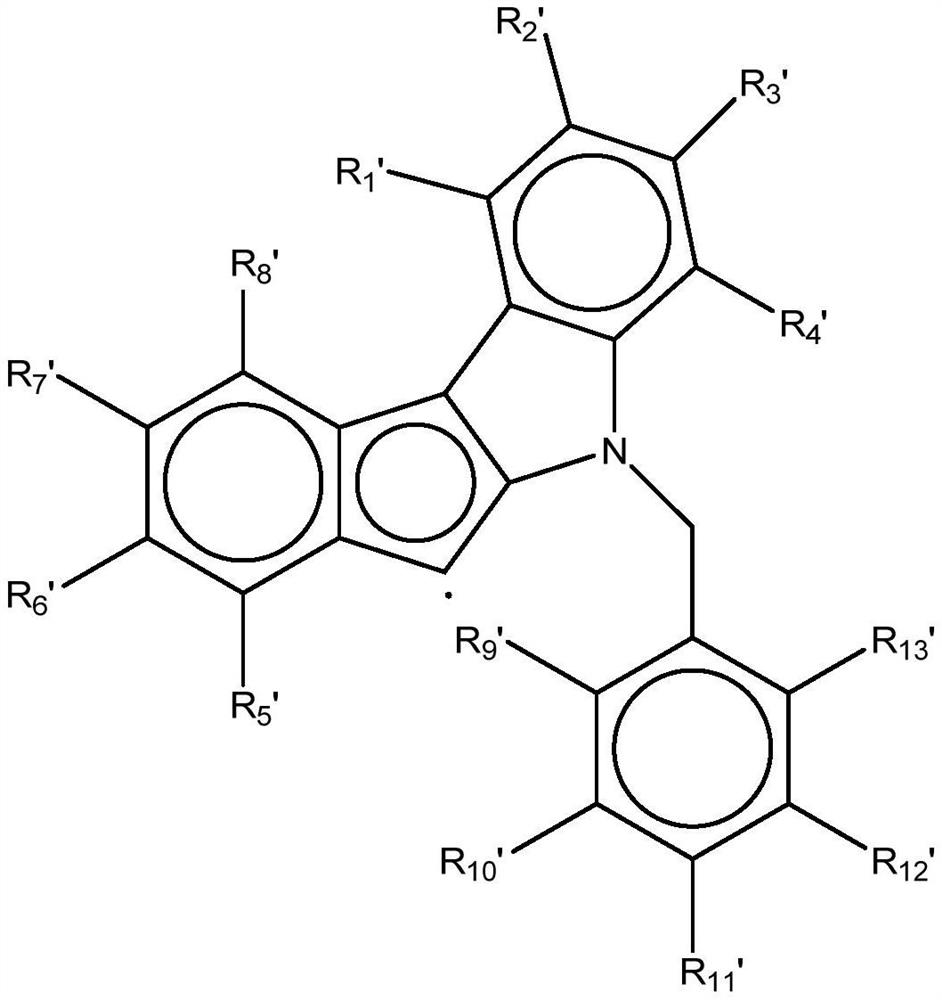

[0073] The method for preparing polyethylene according to the present disclosure may include the steps of: at least one first metallocene compound represented by the following Chemical Formula 1; and at least one second metallocene compound selected from the compounds represented by the following Chemical Formula 3 Polymerize ethylene in the presence of:

[0074] [chemical formula 1]

[0075]

[0076] In Chemical Formula 1,

[0077] Q 1 and Q 2 The same or different from each other, and each independently hydrogen, halogen, C 1-20 Alkyl, C 2-20 Alkenyl, C 2-20 Alkoxyalkyl, C 6-20 Aryl, C 7-40 Alkylaryl or C 7-40 Arylalkyl;

[0078] A 1 is carbon (C), silicon (Si) or germanium (Ge);

[0079] m 1 is a Group 4 transition metal;

[0080] x 1 and x 2 are the same or different from each other, and are independently halogen, C 1-20 Alkyl, C2-20 Alkenyl, C 6-20 Aryl, nitro, amino, C 1-20 Alkylsilyl, C 1-20 Alkoxy or C 1-20 sulfonate groups; and

[0081] C 1 an...

preparation Embodiment 1

[0249] Preparation Example 1: Preparation of Supported Catalyst

[0250] 5.0 kg of toluene solution was added to a 20 L stainless steel (sus) high pressure reactor, and the temperature of the reactor was kept at 40°C. After adding 1,000 g of silica (SP948, manufactured by Grace Davison) dehydrated at a temperature of 600° C. in vacuum for 12 hours to the reactor, and fully dispersing the silica, 25 g of the ethylene oxide of Synthesis Example 2 was dissolved in toluene. A metal compound was added thereto, and then reacted at 40°C for 2 hours while stirring at 200 rpm. Thereafter, stirring was stopped, followed by settling for 30 minutes, and then the reaction solution was decanted.

[0251] 2.5 kg of toluene was added to the reactor, and 9.4 kg of a 10 wt % methylaluminoxane (MAO) / toluene solution was added thereto, followed by stirring at 200 rpm at 40° C. for 12 hours. Thereafter, stirring was stopped, followed by settling for 30 minutes, and then the reaction solution was...

comparative preparation Embodiment 1

[0255] Comparative preparation example 1: the preparation of supported catalyst

[0256] In addition to using the metallocene compound of Comparative Synthesis Example 1 instead of the metallocene compound of Synthesis Example 1, and the weight ratio of the metallocene compound of Comparative Synthesis Example 1 and the metallocene compound of Synthesis Example 2 is 50:50, with A supported hybrid catalyst was prepared in the same manner as in Preparation Example 1.

[0257] [Preparation of polyethylene]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com