Gold-coated silver bonding wire and manufacturing method thereof, and semiconductor device and manufacturing method thereof

A bonding wire and semiconductor technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of not disclosing the composition of gold-covered silver bonding wires, not considering Au entering the Ag wire, and not implying ions Migration and other problems, to achieve the effect of suppressing ion migration, suppressing insulation deterioration or short circuit, and improving manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~44

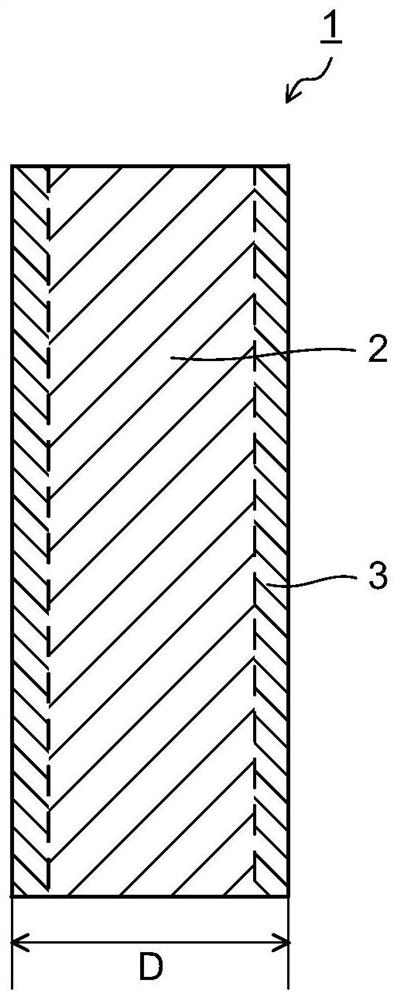

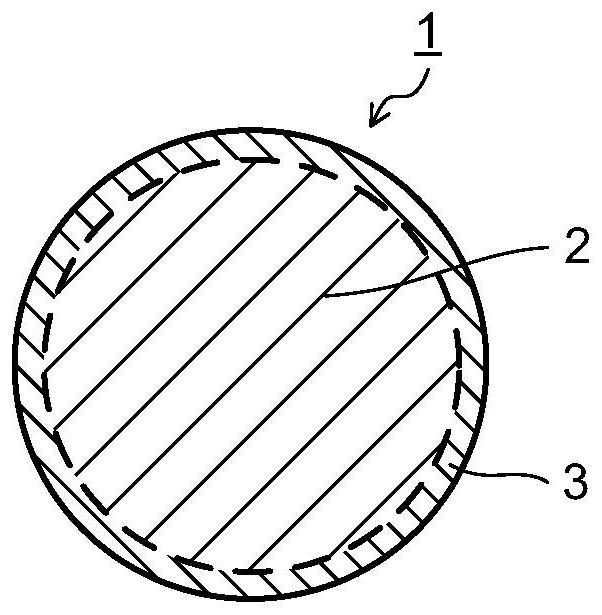

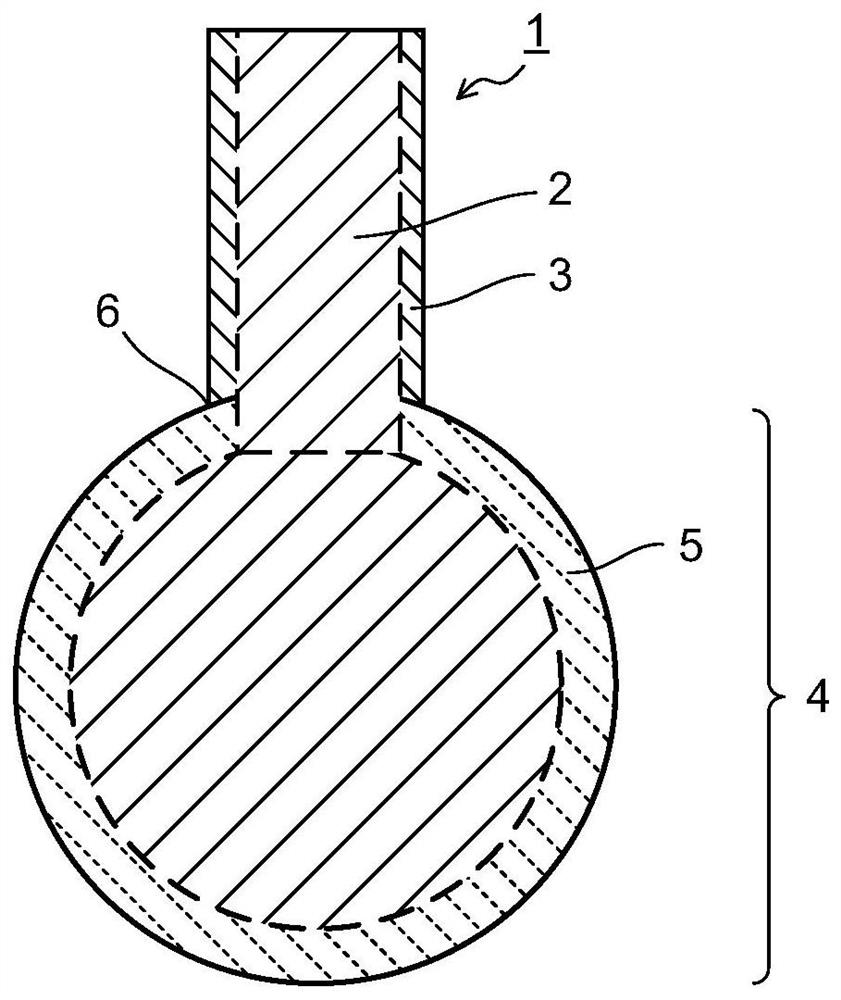

[0085] As the core material, a silver core material with a purity of 99% produced by continuous casting was prepared, and processed by continuous wire drawing to a median wire diameter of 0.05 mm to 1.0 mm. Furthermore, a gold coating layer was formed on the silver wire rod of intermediate wire diameter as follows. In a gold electrolytic plating bath to which additives such as sulfur, selenium, and tellurium have been added in appropriate amounts, the silver wire is dipped while being fed continuously, and the current density is 0.20A / dm in the silver wire. 2 ~1.0A / dm 2 A current is passed to form a gold capping layer containing chalcogen elements. Thereafter, the final heat treatment was performed on the wire drawn to a final wire diameter of φ20 μm, and the gold-coated silver bonding wires of Examples 1 to 36 were produced. These gold-coated silver bonding wires were used for the characteristic evaluation mentioned later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com